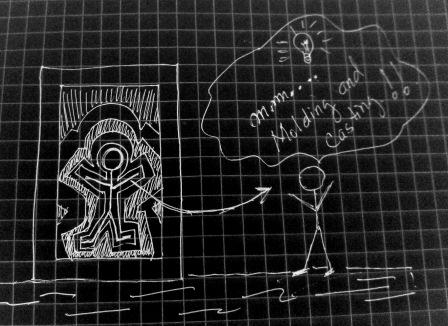

| Week9 | Molding and casting |

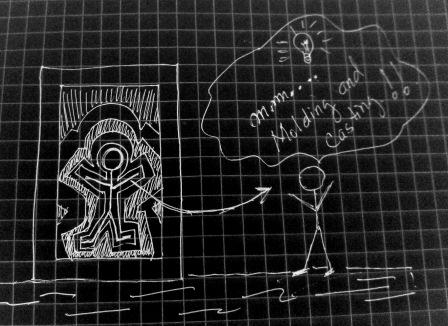

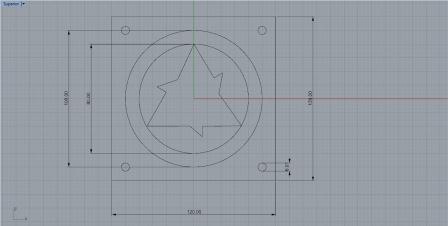

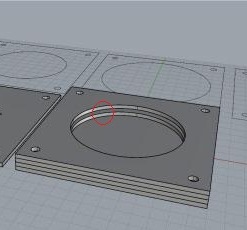

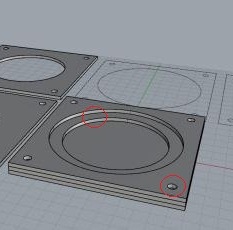

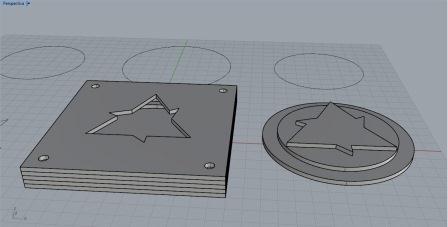

Design in 2D model |  Separation in 2D model levels |  3D Molds considering a thickness of 3mm |  Armed with two levels of mold |

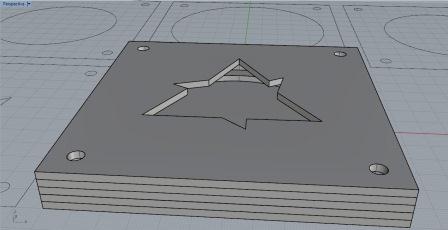

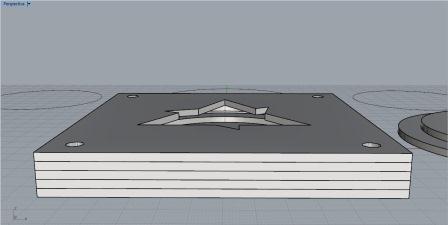

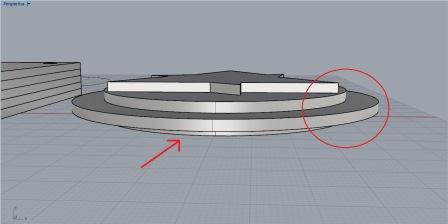

Armed with 4 levels of mold |  Full cast |  Interior detail of the mold |  Mold and Model |

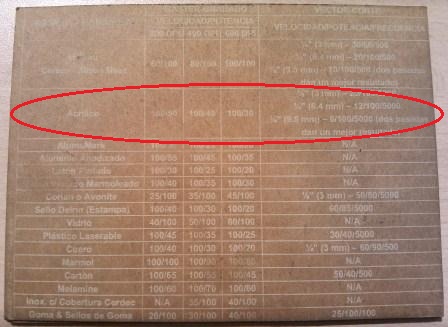

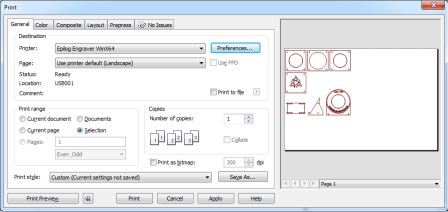

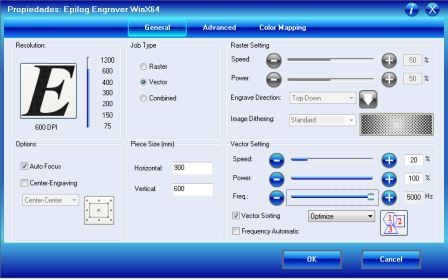

Setting the printing of models for laser cutting. |  Configuration parameters for laser cutting. |  Results of using laser cut acrylic 3mm thick. |

Mold levels are fixed by screws, and are filled one by one. |  After waiting about 24Hours and moistening every 6 hours, proceed to unmold level by level. |  The results of stripping allows us to observe that at the time of pouring the material into the mold air bubbles are generated that prevented the material covered the entire volume. |  Unmold second level |

Unmold the third level |  Unmold the fourth level |  Side of the model where all levels are appreciated . |  Details imperfections generated by the air bubbles. |