Electronics Composites Assignment

Week of April 9, 2014:

This week's assignment is to: design and make a 3D mold (~ft2), and produce a fiber composite part in it.

Electronics Composites Assignment Week of April 9, 2014: This week's assignment is to: design and make a 3D mold (~ft2), and produce a fiber composite part in it. |

|

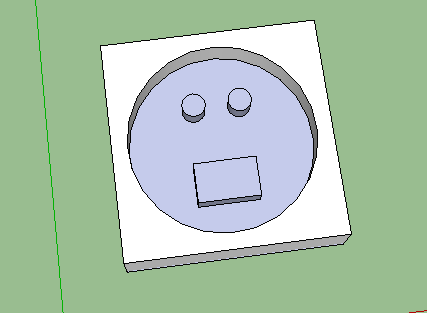

| 1. My lion/scarecrow face designed for the Molding/Casting assignment was too big for the Modela. I think this project was destined for a foam mold created with the ShopBot and then filled with epoxy applied to burlap. First step was to design a mold in SketchUp. The rectangle is 14 x 14 inches. The face is 12 inches in diameter. I have located old bicycle reflectors for the eyes and mouth. |  |

2. Remembering the lessons with my molding and casting

project and universal mold release, I had an experiment with

silicone spray and epoxy-laden burlap and foam. The burlap

did not "release" from the foam. I went with vegetable oil

for my release agent. After the epoxy cured, the good news

was the single strips of burlap released from the oil coated

foam. The epoxy however pooled thickly through the burlap in

multi-layered regions and did not release from the mold. I

resorted to the ultimate release agent for the foam:

acetone. |

The single strips of burlap were too thin, brittle, and

broke easily. The overall end product was very different

looking than my original plan. However, I learned about

composites and I learned about epoxy. That's progress.  |

3. 6/14/14 The Guardian of the Geese is glued onto his

dogloo outpost. |

Mickie Flores Home |