Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog

07. Computer Controlled Machining

This weeks assignment is to 'Make Something Big' on the

shopbot. So we have available a 3-axis CNC milling machine

with an 8 foot by 4 foot bed and as much 12mm plywood as I

need. As I'd designed my press fit 'Castle Construction Kit'

from week 3 parametrically I decided to simply scale it up for this

weeks task, so I'm aiming for a castle construction kit that a 5

year old could use as a playhouse.

07.01 Design Tests.

My first task was to get to grips with the tools and workflow for

using the shopbot. So I used this as an opportunity to do a

couple of design tests of joints hinges and sizing.

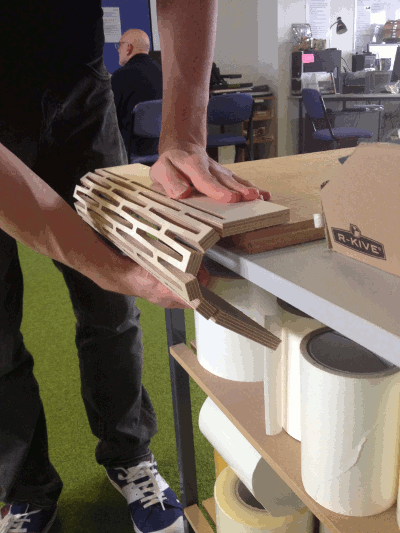

07.01.1 Hinge Test

One of my fellow students was testing a hinge design on the shopbot

for his project. The initial test was very stiff and had less

flex than he had expected. As I wanted hinges to allow my

castle towers to wrap around into shape, I decided to examine the

design, try to understand what was wrong and then improve it.

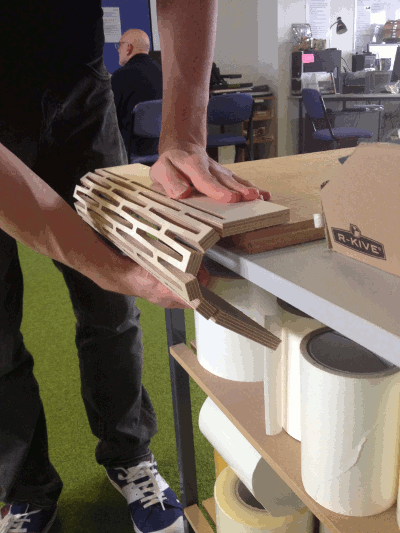

Below is a picture of my improved hinge design marked to show where

the flex in the hinge comes from.

By maximising the length of the section marked in red you can

maximise the flexability of the hinge. I designed this test

part completely in 'Partworks3.5' as a test of this tool path as the

rest of my design was in kokopelli. CRV file here.

07.01.2 Koko Toolpath Test / Scale Test

Moving on from this I decided to do a quick test in kokopelli.

I wanted to see what the work flow was to get the files from

kokopelli onto the shopbot and check what scale my final part would

come out at.

I would like to test using the CAM panel direct from kokopelli,

however our shopbot computer doesn't currently have fab modules or

kokopelli installed, I've started to rectify this, but more time is

required to get Ubuntu updated to a suitably current version.

I also want to test Neils prefered method of CAD->PNG->Shopbot

vai fab modules. My kokopeli test file is here.

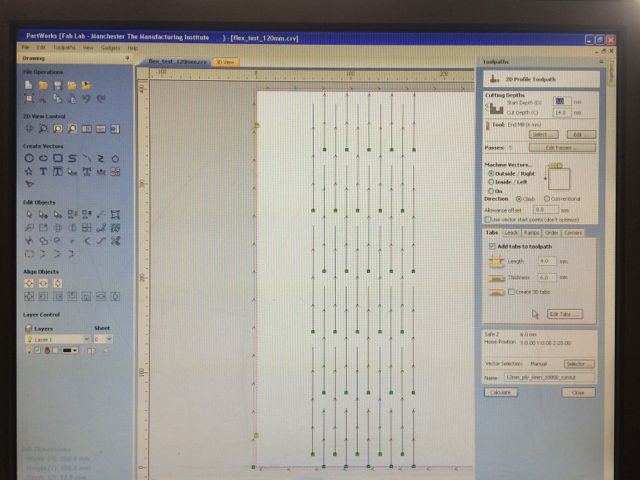

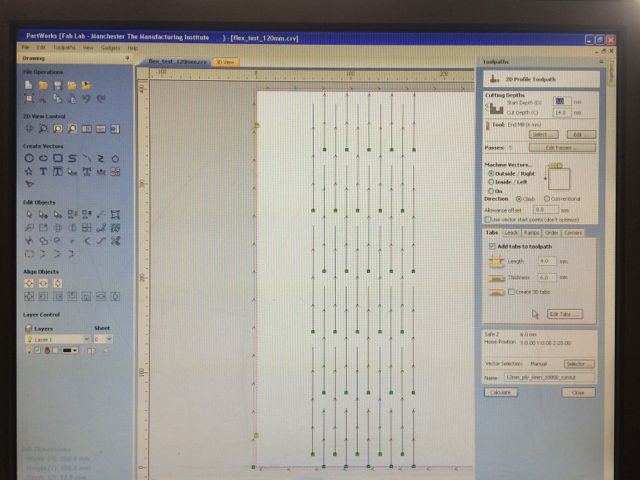

- So I decided to export my files from kokopelli into Partworks

and go from there.

- I exported to svg from kokopelli. Resolution default of

10 pixels/mm.

- I imported the svg into Inkscape.

- Export from Inkscape as a pdf with no modifications.

- Open this PDF in Partworks.

Once in Partworks I noticed that the vectors in this file were

'fragmented' into smaller sections and that I had some extra vectors

across tabs etc that I needed to delete manually. I created

the tool paths as before but when I previewd the part some vectors

in the origional design were not being cut. I had to add

another step and 'join' all of the vecotrs into one continuous loop

once I had imported the PDF into Partworks to fix this.

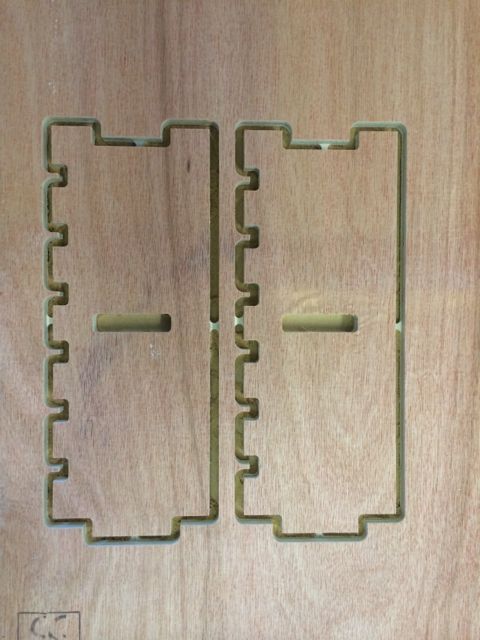

It took a couple of iterations to make sure that I had the scale

factors correct and that the part was going to come out at a

sensible test size. Once I was happy with this I cut two

copies on the shopbot.

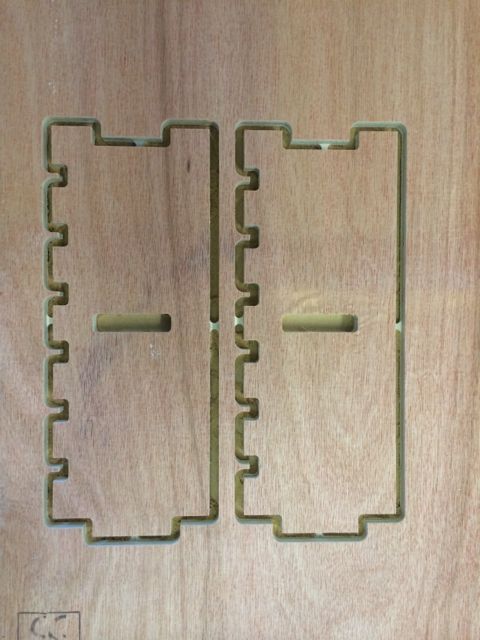

My first test part was to check scales and tolerances of the end

tabs, so it had no dog bones on internal corners and the joints

(particularly the center slot) wouldn't work.

07.01.2 Joint Test

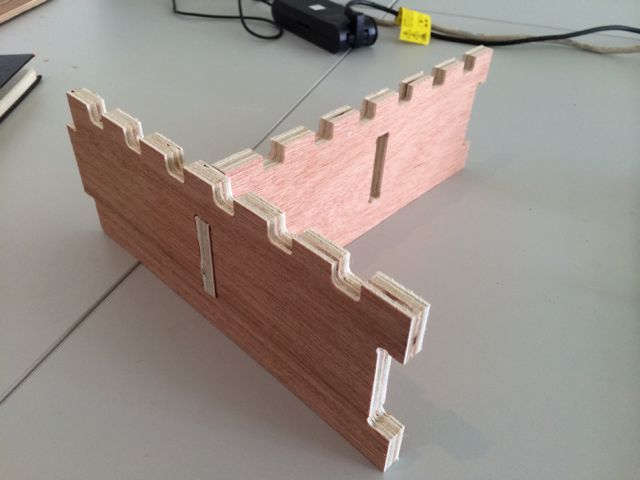

So I went back to kokopelli, added dog bones, and re-cut to test the

joints. I could have added these dog bones manually in

Partworks. However I wanted to reduce the number of additional

manual operations required in each design itteration, so I made them

part of the kokopelli design.

The external / internal dimensions of the tabs work OK, but I'd like

to cut a series of test slots to correctly gauge the tolerances

required for a good interferance fit. I also noted that my

12mm ply was actually only 10.8mm thick.

07.02.3 Joint Test 2

I then moved on to creating a variant of the MTM snap joint in 10mm

ply. This uses the same design file as

week 3 'Press fit kit', just set the machine type to 'shopbot'.

This joint works, but in order to get the flexibility required the

'tangs' need to be longer than in the 3mm ply version. Also

the 10mm ply used is lower quality than our 3mm ply. It's full

of discontinuities in the internal material layers that create weak

spots. This joint design regularly snaps in this material.

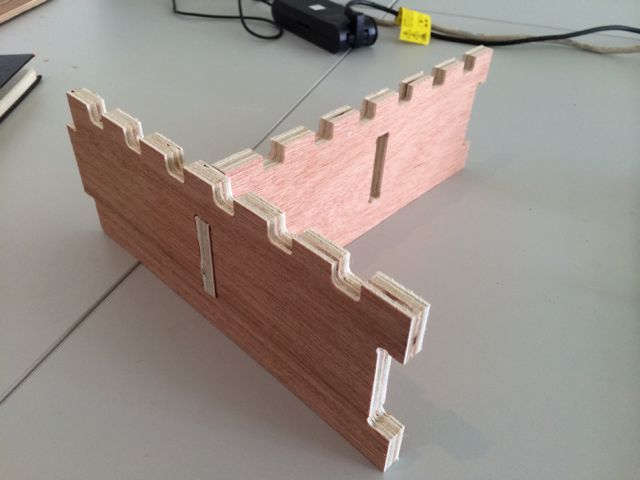

07.03 Cut Real Thing

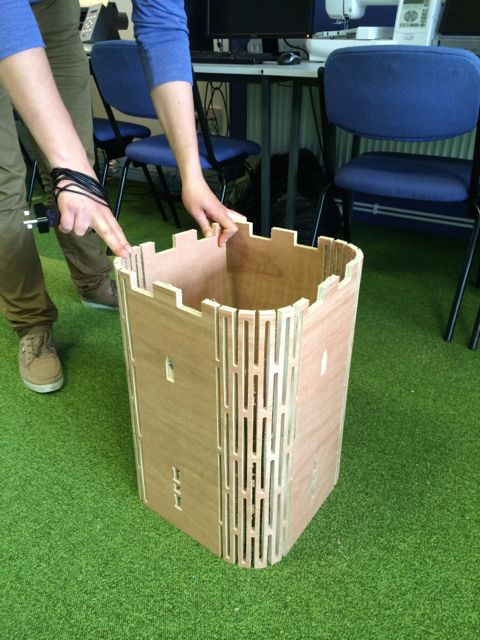

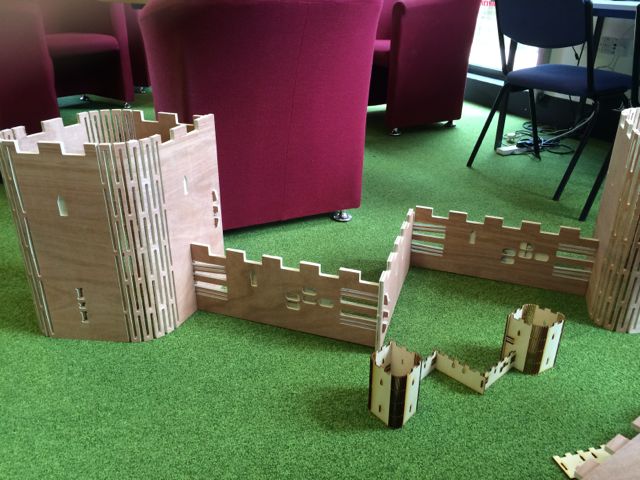

Again the same design file

was used as week 3 'Press fit' but with the machine type changed.

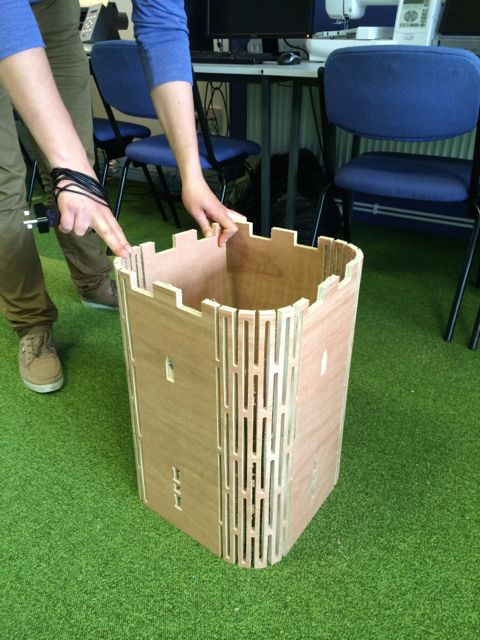

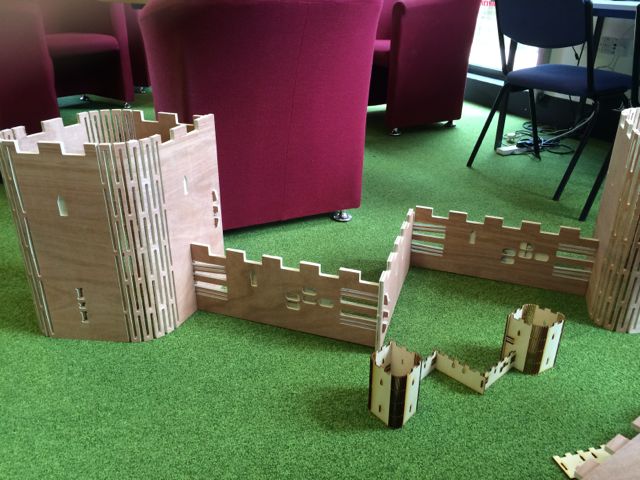

Above left - tower section before assembly. Above right - wall

sections.

Above - tower section folded into shape.

Above - The big and little versions of the castle together.

Further Unordered Thoughs...

Cut a 3D profile in foam, to test the 3D tool paths.

Try one in thicker laminated wood?

Fab modules and Kokopelli onto shopbot PC or drive shopbot direct

from my mac.

Test CAD->PNG->Shopbot vai fab modules.

Tabs are great, you can easily remove them with a craft knife.

Test cut with different slot sizes. Koko export error...

Test cuts with 6mm down cut and 0.25inch compression cut

compression:

no space to ramp in?

tool gets very hot and whilst no problem do get

'burning smell', also cut surfaces are 'blackened'. Tool

blunt?

really glowing embers, see photo, so stopped job. turns

out speeds and feeds for tool into tooldb were wrong! Tool

going too slow!

corrected and cuts really quick and well.

measured with calipers:

test tab cut with 6mm down cut 50.1mm

test tab cut with 0.25inch compressiion 51.5mm, even though

tool size was correct. Surface internal to material is much

rougher!

Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog