Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog

Modifying a Tower Pro 9g Micro Servo for 360 Degree Rotation

The idea is to re-purpose a servo as a cheap alternative to a

gearhead motor. Note ince you have made this modification it

will be impossible to undo it and put your servo back to normal

operation.

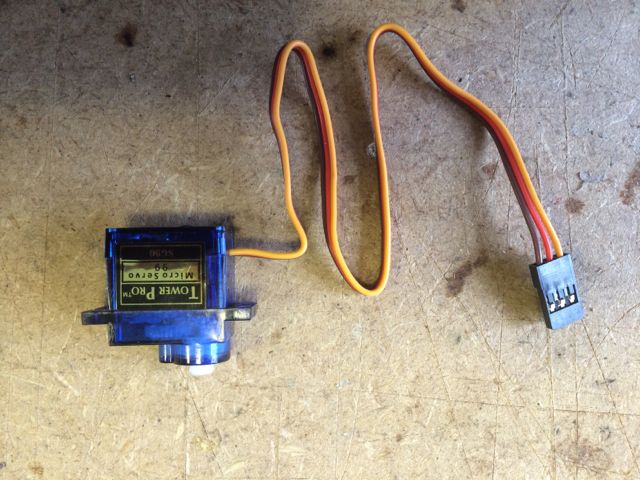

The Tower Pro 9g I've used here can be found for under £3 from many

different suppliers in the UK. It's a small, light (9 grams),

cheap, easy to get hold of all over the world and has a high torque

output (Stall torque: 1.2 kg/cm at 4.8V). The only real issues

are that the plastic gears are quite cheap and so the servo

longevity under high loads will be an issue. However at this

price they are ideal for prototyping and can be onsidered throw away

devices.

There are two ways that this can be achieved:

1. Keep the existing control electronics in the servo.

Pros:

- No need for extra driver elecctronics external to the

servo. A PWM signal can be used to drive the servo

forwards, backwards or stop it.

- Only a single output pins is required per servo.

Cons:

- Number of PWM outputs on the AVR is limited, so solution

doesn't scale beyond a couople of servos without scaling to

multiple AVR's.

- PWM signal must be generated exactly in the servo 'dead' zone

to stop the motor rotating.

2. Throw out the existing control electronics and connect directly

to the motor in the servo.

Pros:

- No need for PWM outputs.

- Can easily generate a 'stop' rotation.

- If a PWM output is used the motor speed control is possible.

Cons:

- Requires an H-Bridge driver on the host PCB.

- Requires twice as many output pins on AVR.

I've decided to go with option 2 for my servo modification.

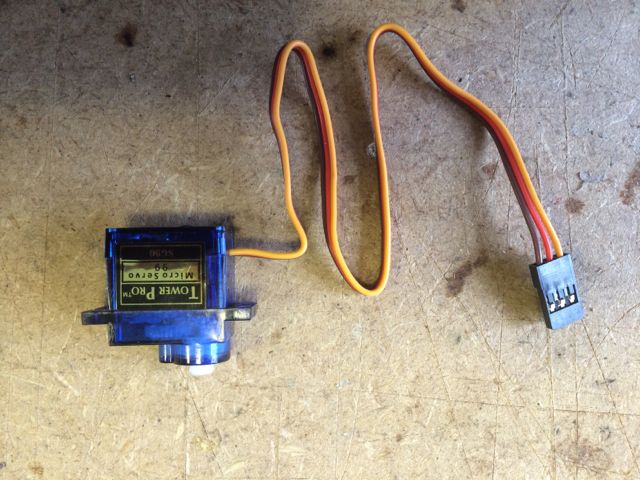

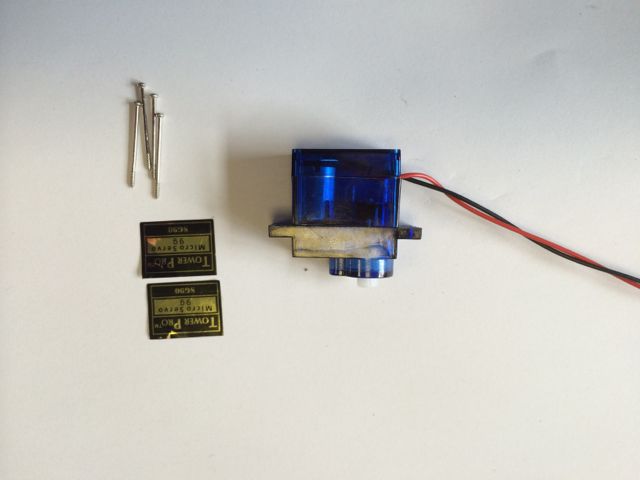

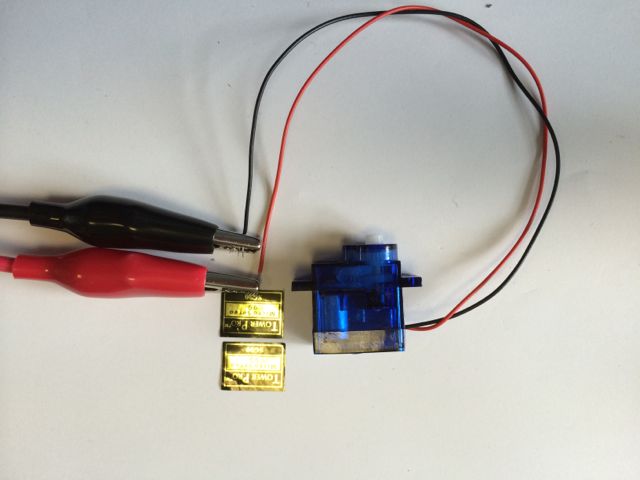

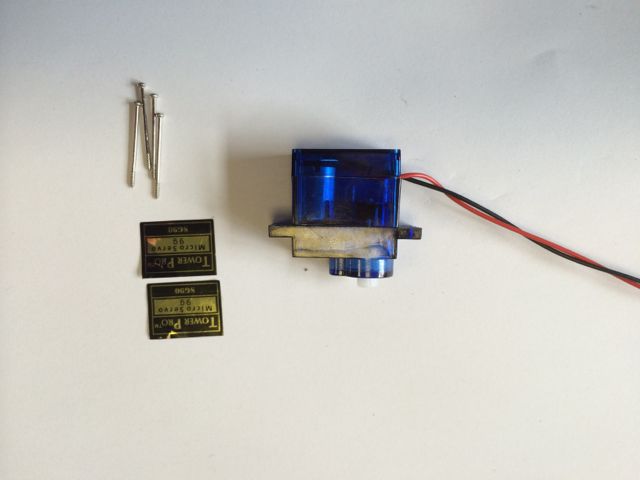

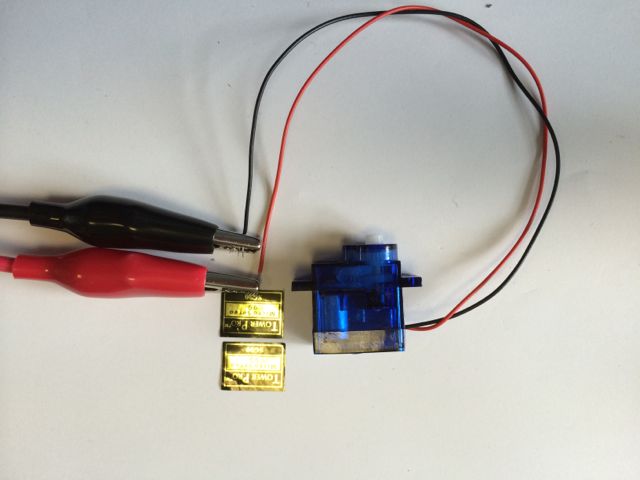

Tower Pro 9g servo before modification.

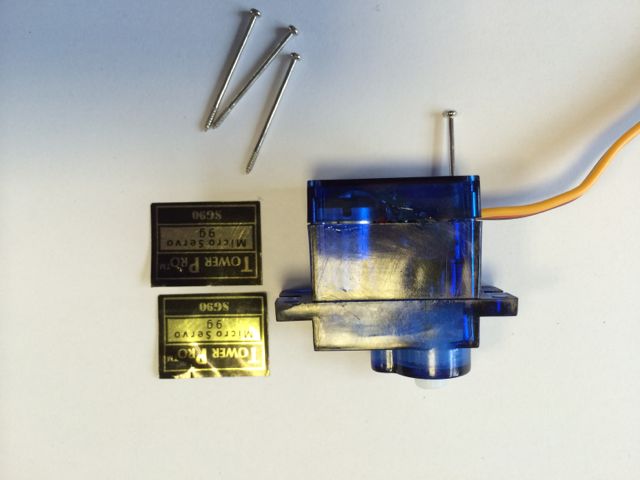

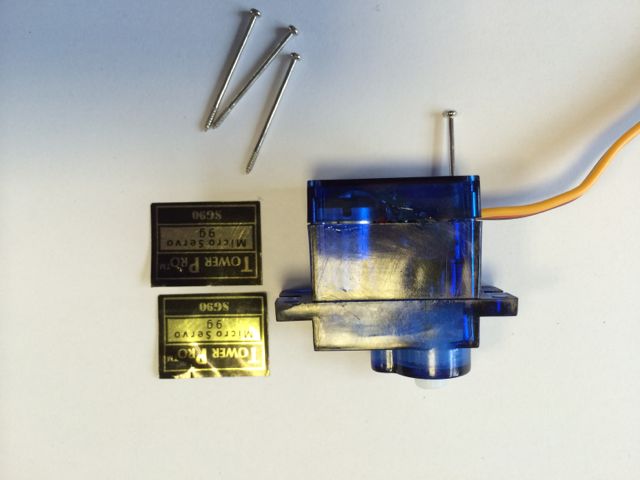

Step 1, Carefully remove the stickers and 4 small screws that hold

the servo together.

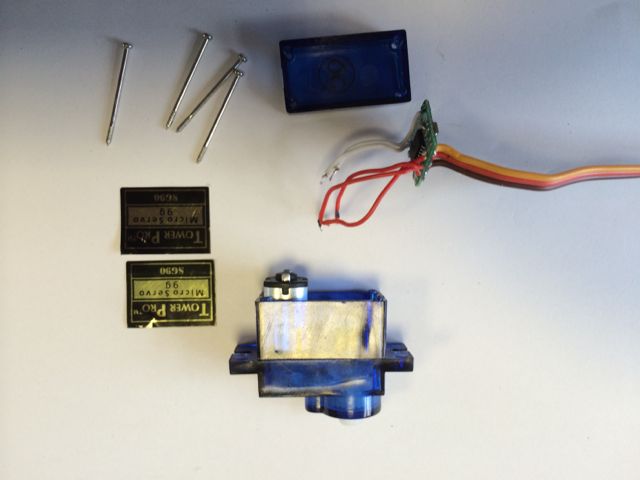

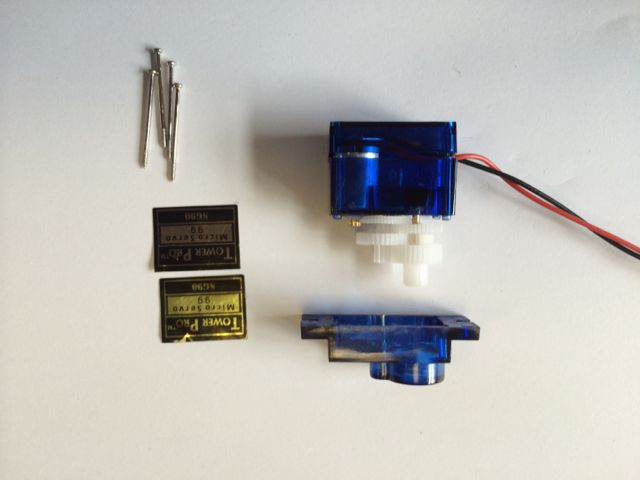

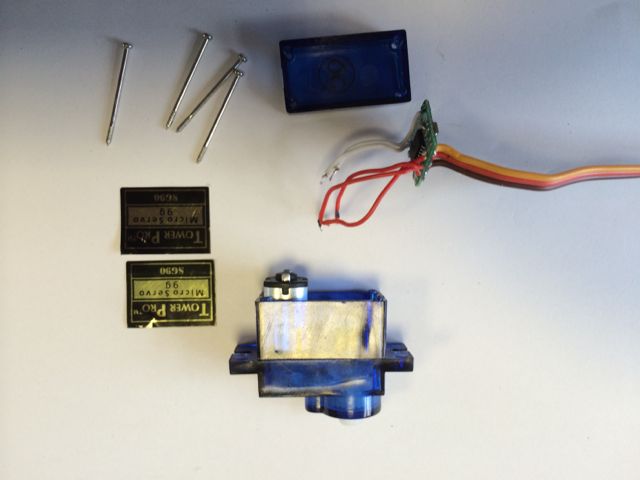

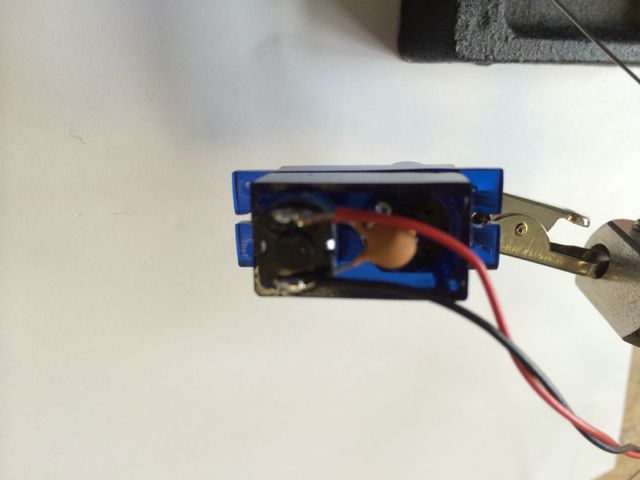

Step 2, Remove the base of the servo, de-solder and remove all the

internal electronics. Make sure to leave the potentiometer in

to servo as it acts as a spindle for the internal gears. The

electronics are mo longer needed, but the cable can be re-used for

later steps if required.

Step 3, Solder a 0.47uF capacitor across the motor terminals.

This just removes the electrical noise generated by the motor as it

spins.

Step 4, Solder a pair of wires to the motor terminals. You can

re-use the wires from the control electronics if you want.

Step 5, Replace the cover over the bottom of the servo, don't screw

in place yet.

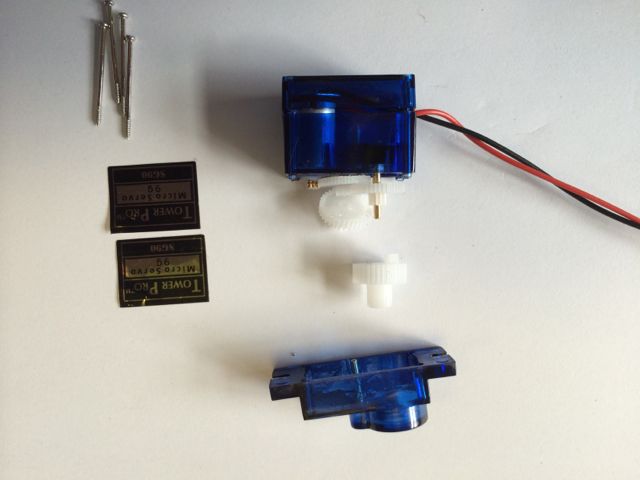

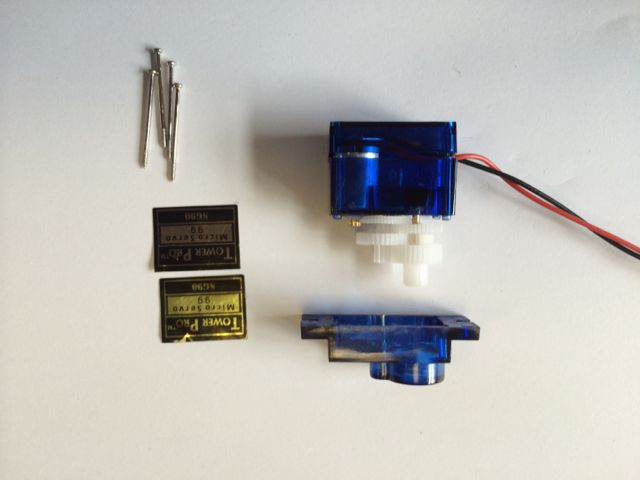

Step 6, Remove the top cover over the gears. Be careful to

note the location of the gears and not to disturb them. Note

that the metal spindle often comes away with the cover leaveing the

middle 2 gears loose. This isn't a problem, just be careful to

note where they go so that the can be put back correctly when

everything is re-assembled.

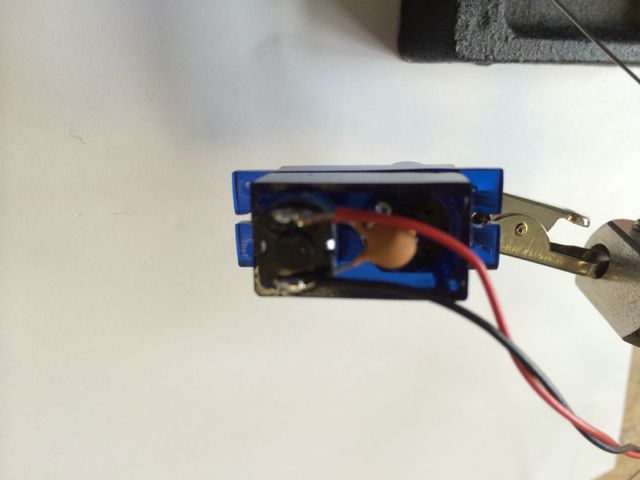

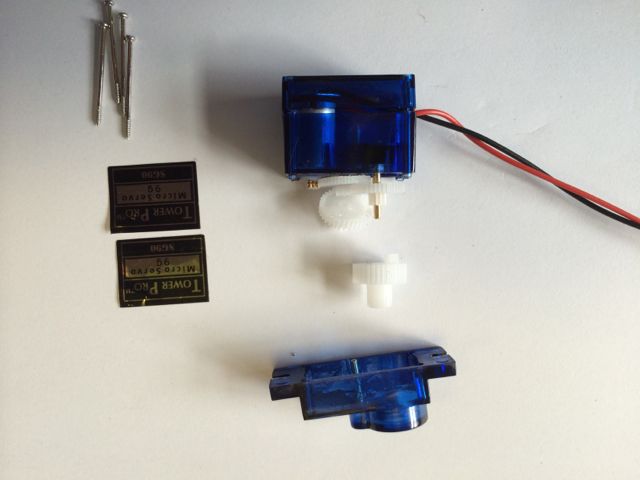

Step 7, Remove the final drive gear. This is press fitted to

the metal potentiometer spindle and requires slight 'persuasion' to

remove.

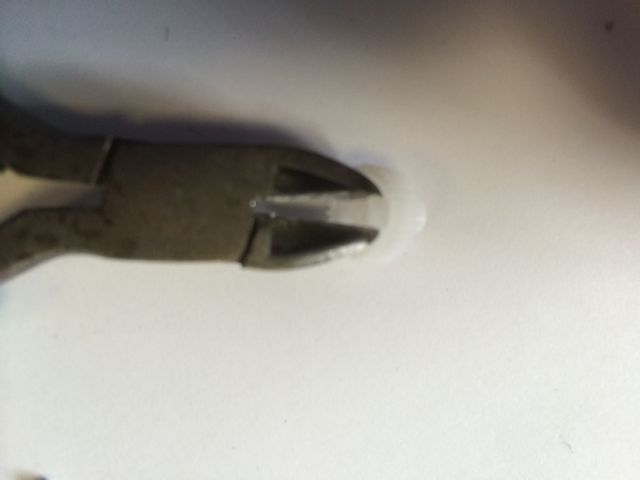

Step 8, Use a set of small side cutter snips to remove the plastic

'end stop' tab on the underside of the final drive gear.

Step 9, Manually enlarge the hole in the center of the final drive

gear with a 2mm drill. This will allow the gear to spin with

no resistance on the shaft of the potentiometer. There is no

need to make the existing hole any deeper, only to enlarge it

fractionally.

Step 10, Re-assemble and test.

Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog Fletch's Fab Academy 2014 Blog

Fletch's Fab Academy 2014 Blog