Fab Academy 2014

The assignment this week was to create a press-fit

construction kit and try something out on the vinyl cutter as well if possible. Due to my hectic travel schedule last week, I missed the live

lecture and had to tune in expo de facto with the uploaded version on vimeo. I have some experience using

a laser cutter, but was excited to get a more in depth introduction to the tools.

The assignment this week was to create a press-fit

construction kit and try something out on the vinyl cutter as well if possible. Due to my hectic travel schedule last week, I missed the live

lecture and had to tune in expo de facto with the uploaded version on vimeo. I have some experience using

a laser cutter, but was excited to get a more in depth introduction to the tools.

I also got in touch with Aser back in Egypt and he summed up the assignment very succinctly with these three points:

- Joint Design

- No Glue (ANYWHERE)

- Reconfigurable

While teaching in the Bronx, I started an FLL team called the Boogie Down Bots. Our website and blog were both fully maintained by students on the team. I'm still so proud of the robot we made our second year that I've got to insist you check out this video of the robot in action.

Did you check out that video? Good. As part of our team effort, some particularly industrious members of the Boogie Down Bots silkscreened hundreds of shirts, dozens of hoodies, and innumerable flags. We used this logo for most of our branding:

I decided that a fitting tribute would be to make a sticker for my laptop. I removed the gears to get a simpler skull image, and created this .png file. After a few attempts (one of which involved using the wrong transfer material!) and some fiddling to get the curves right, I ended up with this beauty for my laptop (I've got a black case on the laptop and I thought the red sticker was a nice contrast.

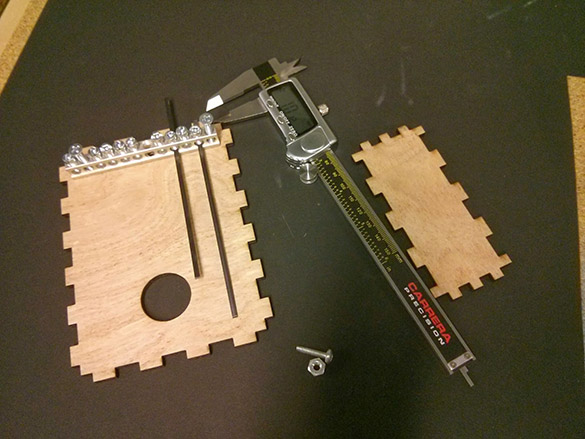

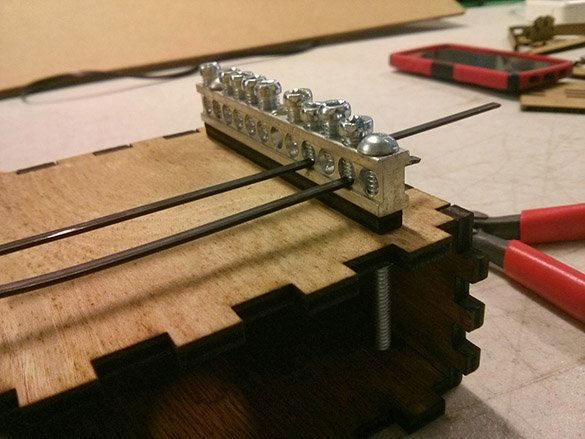

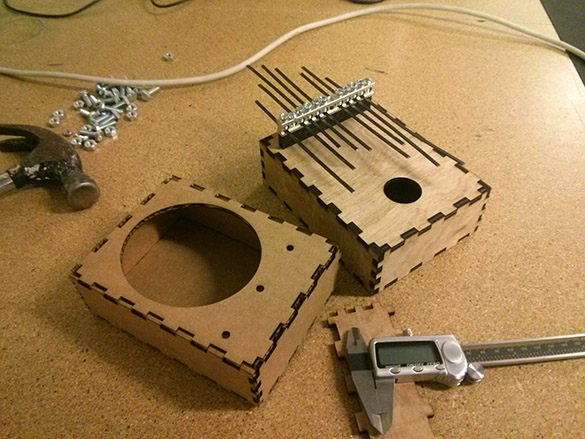

For my laser cutting project this week, I had planned on creating a kalimba which would be mounted on tracks to create a train similar to this. Unfortunately, I only had one day in the lab, so I decided to focus on creating the kalima first. I found this tutorial on Make, so I ran to Home Depot just before heading to Providence, and picked up an electrician's grounding bar and a roll of electrician's snake.

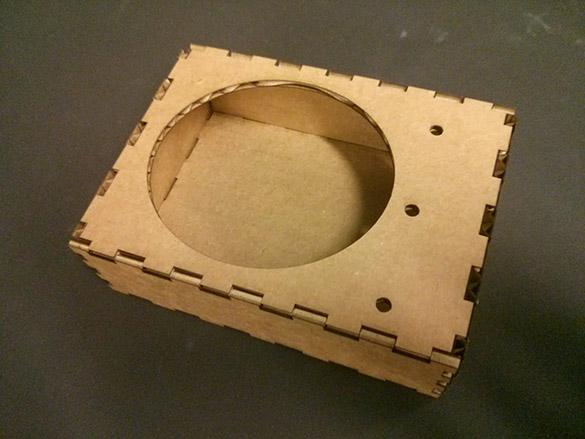

After a few attempts using Inkscape, I decided to try installing a parametric box script. However, I ran into some issues with python that didn't seem worth the trouble of sorting out for a box, but I got a great browser based version from some classmates - "Magic Box". This allowed me to quickly get a box prototype ready to cut out of cardboard so I could have a 3D model to check my measurements with.

From here I moved on to trying to cut something out of plywood. I also realized that giving the time constraints I probably was not going to be able to cut a track system that would work, so I decided to focus on producing the kalimba itself. I've linked to a track design in the tutorials section which could be a possibility for further expansion.

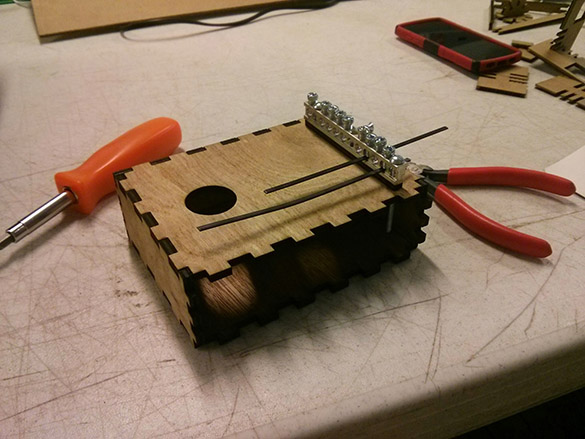

The fit was a little too loose after my first pas, so I needed to adjust my tolerances a bit after my first test. Since I had used Magic Box I wasn't able to adjust tabs via cloning in Inkscape. So, I broke the path, and increased the tab section by about 6 percent to get a tighter fit. Since this would have caused the corners to stop fitting properly, I only adjusted the tabs along the edge rather than any of the corners. I also opted to leave the side panels slightly looser so they could be removed to adjust the tines as necessary. Not exactly reconfigurable, but close I guess.

The first two tines went on nicely, and I hoped I could test to see how the kalimba sounded. However, I needed to have the box assembled first, and it seemed like it needed to be on a larger surface to resonate properly and produce louder pitches. So, I finished putting it together, cutting and adding additional tines... and it worked!

(which allowed me to adjust laser strength for a single pass

Lessons learned:

- Make a pressfit tool to check tolerances

- Try experimenting with other joints like these