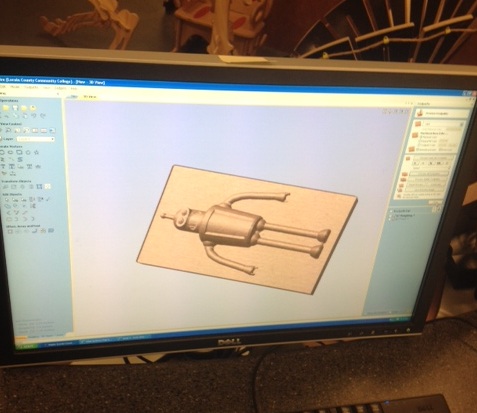

Bender robot in Aspire.

This week's project required very little physical work, but needed a lot of time and preparation. I couldn't decide on what to make a mold of. Then it just suddenly hit me that I could make something like a non-flexible action figure or refrigerator magnet. I decided to cast Bender the robot from Futurama. I found a very simple line drawing of Bender and simply extruded his features until he was 3-D and realistic to the cartoon.

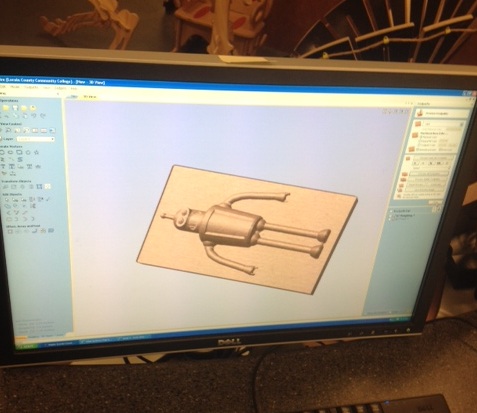

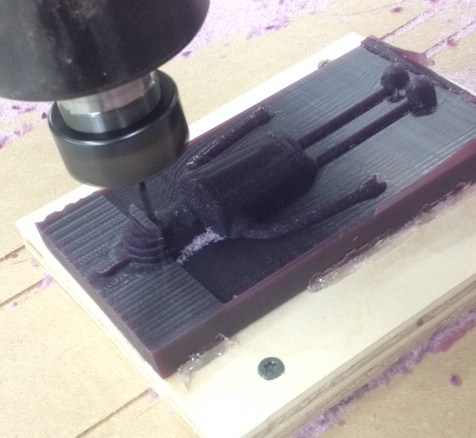

I took the 3D file and imported it to Aspire, where I am able to make a toolpath for the Shopbot. This was very simple since I was only making the front face of the robot. The actual time it took to mill out the robot wax mold was over an hour! It was only 4.5 inches long. I

I mixed the Smooth-On chemicals to create a cast of the mold. I surrounded wax Bender with cardboard walls that were covered with aluminum to avoid sticking. The Smooth-On leaked in a very small corner that was easy to clean up. It dried and solidified overnight.

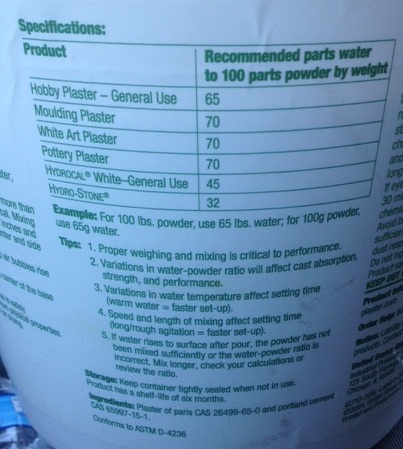

I then mixed the Hydrostone powder with the recommended amount of water to create the casting material. I tapped the plastic cup I was mixing in to allow air bubbles rise so as not to affect the outcome of the mold..

Bender robot in Aspire.

Wax mold of a mold being cut out.

Bender almost completed after over an hour.

Hydrostone mixing instructions.

The arms and legs were too thin and brittle. The separate pieces dried separate from each other. The extremities are .125" thick. I'd say that anything thinner than .50" will not last as a hydrostone mold.