Press fit kit in laser.

Luckily, I have had some experience with blender, but I am not proficient in it right now. I am actually getting help with it right now. I have a blender tutor whom I have set up an informal meeting with every weekend. We only covered how to draw simple shapes in Blender. I know that Neil did not mention Google Sketch Up as one of the softwares to use, but I understand that it is possible to convert a Sketch Up file and import it to other platforms. My project right now is a smart entertainment/ambient lighting system that can follow subjects on stage or in an environment. It is called HALO (High Adaptive Lighting Orbiters)

On Friday (Valentine's day!) I worked at the Lorain County Community College (LCCC) making a cardboard press fit kit for my assignment. It was frustrating, but the finished product was pretty fun! I got to take home my own little perishable K-nex set. Scott Zitek from the Lorain Fab Lab was (and is) a HUGE help in my process. I was fortunate enough to meet him last year as the head instructor of the Fab Lab Boot Camp.

I used Corel Draw to make the shapes. Each piece has a .125" gap for connecting. The cardboard was .125" thick. The edges are slightly chamfered. I made some very basic shapes in a verity of sizes and put press fit joints in the corners and edges of the pieces. For printing I used the Epilogue lassr. I applied a vector setting of 26 Speed / 100 Power / 5000 Frequency. Two pieces cam out slightly scorched but were still useable.

Press fit kit in laser.

One sheet from the press fit kit.

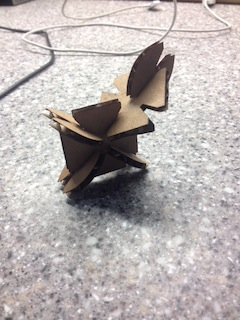

A press fit "animal"!

Several play structures!

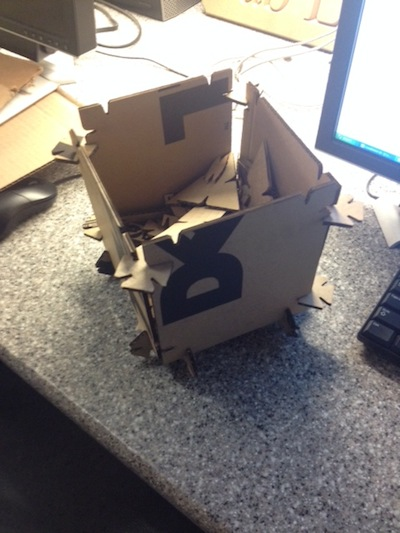

A pressfit box to take my kit home!