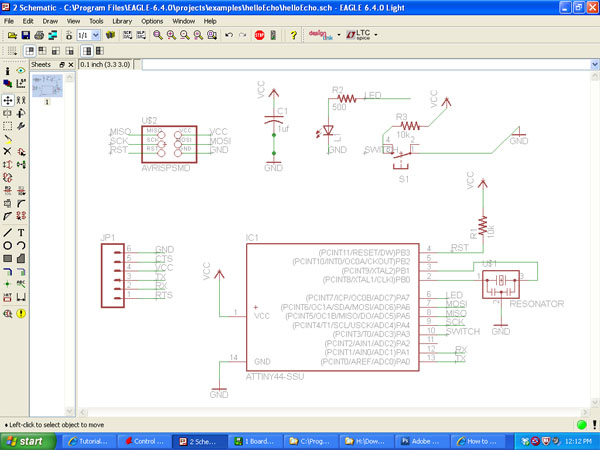

This week our goal is to add a button and a LED to the hello-world board design and make it.

This week we will learn to use Eagle to modify the design of a PCB and then use the Modela milling machine to remove the excess copper from a FR1 PCB leaving the traces from the new design, and then adding surface-mount components (stuffing).

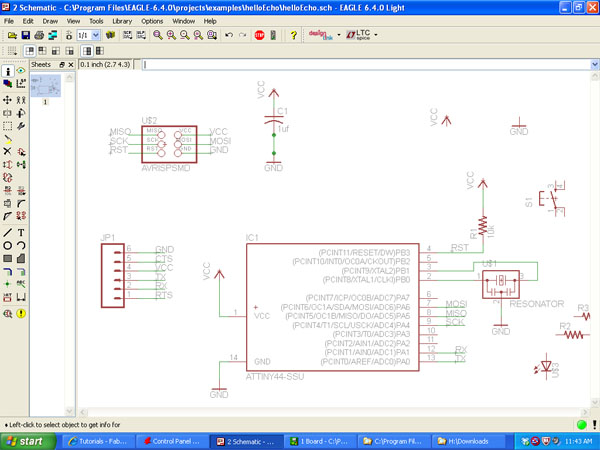

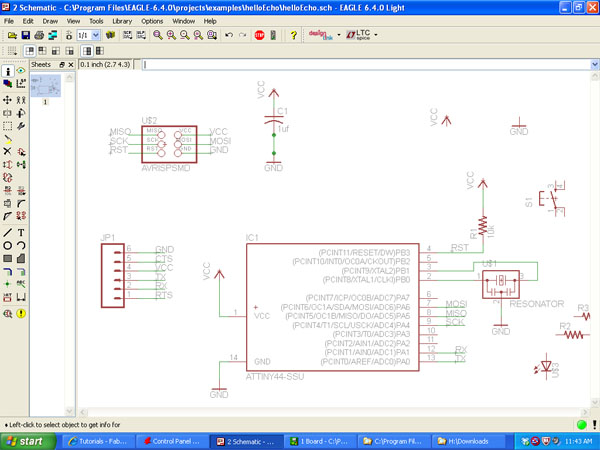

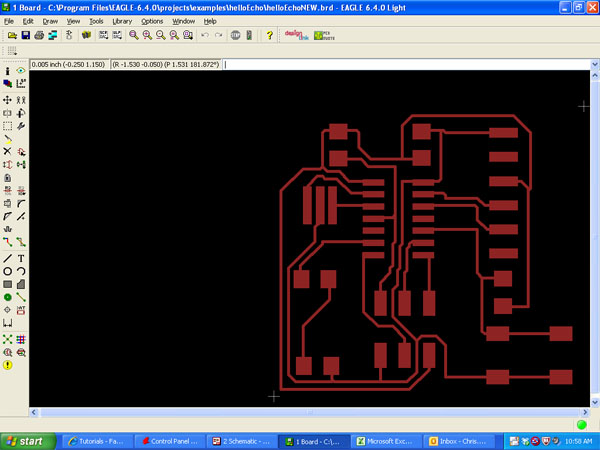

The first half of the week was spent learning Eagle. I began with the hello-world schematic.

Adding the components took a bit of time to understand, but once it made sense, it went fairly quickly. The difficult part for me was creating the traces without crossing the traces and leaving enough room for the parts to fit. I used the automatic feature and eventually managed to get all of the parts to work. I ran the ECC check - passed.

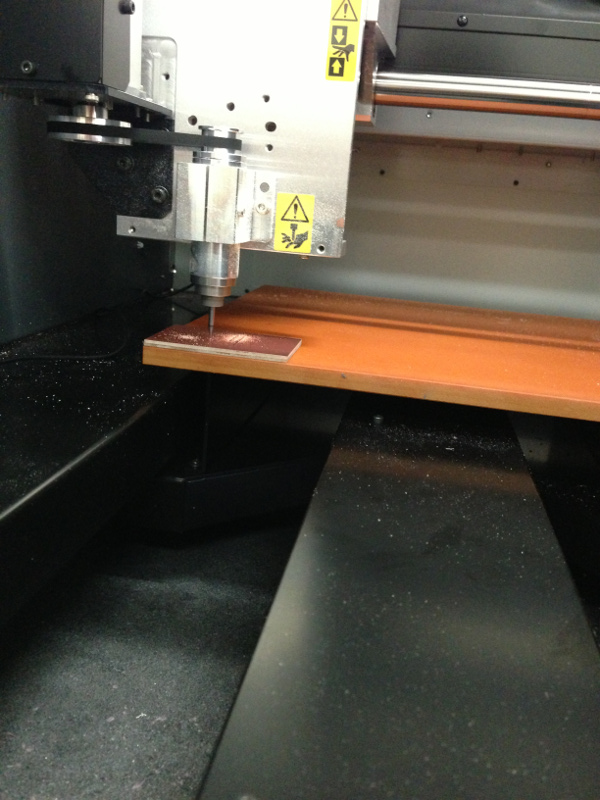

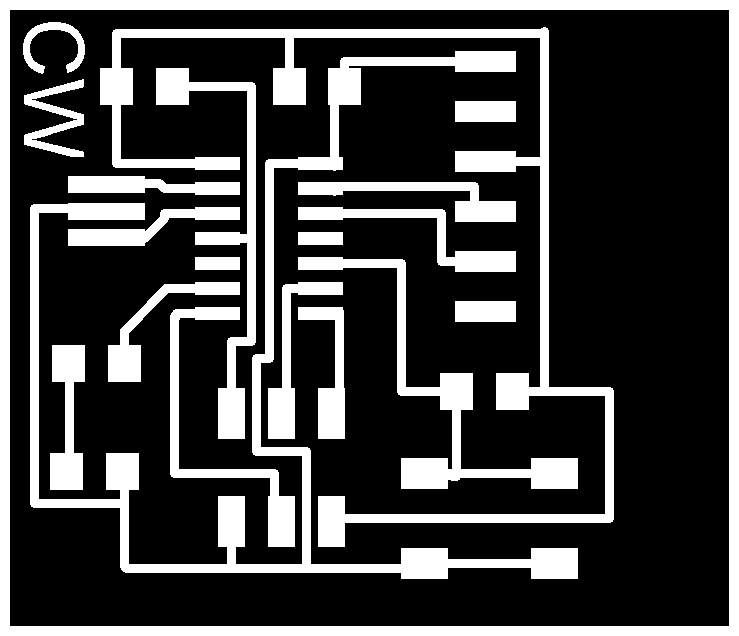

I created the .png file of the traces and moved over to the milling machine.

I placed the board on the cutting surface (with a sacrifical board underneath just in case) and zeroed the bit on the surface to the board. This is getting much easier. The first attempt of cutting the board failed, but only because a part of the board must have been a bit lower than the rest of the board. Without removing the board, I zeroed the z-axis on the poorly cut portion (the lowest) and recut the board. I cut out the outside and removed my board.

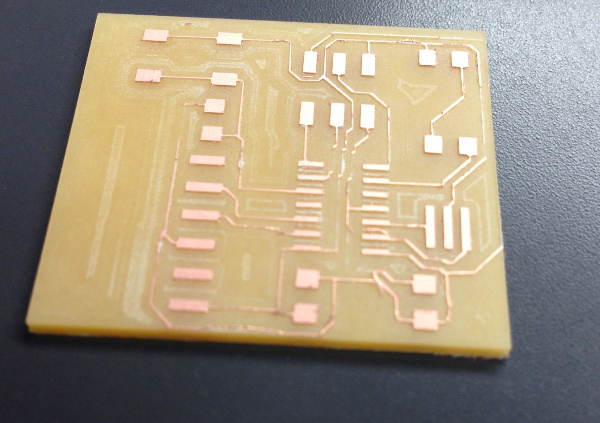

Disaster! The traces were much too small and flaked off when I washed the board. Even my initials came off. I suppose in retrospect, I don't really want my name on a board that poor anyways. I went back to the (Eagle) drawing board.

This time I managed to get the traces to fit without the need to make them as small. I made the board a bit larger to give myself more space to solder and also took that into consideration in placing components.

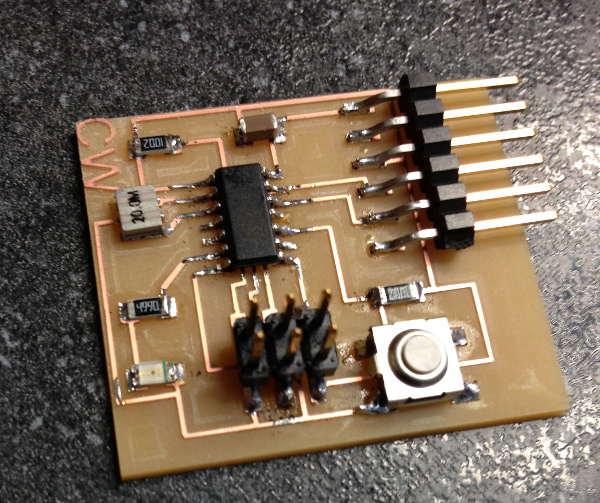

I milled the board - Success! It is so much better this time.

Now came the time to stuff the board. I began to solder the parts onto the board. The soldering became much easier this time. I even used the braid to make my connections look better. I had a bit of trouble with the resonator, but eventually placed my solder on the traces and then used the heat gun to place the component on the board.