This week our goal is design a part on the computer and create it using composite materials.

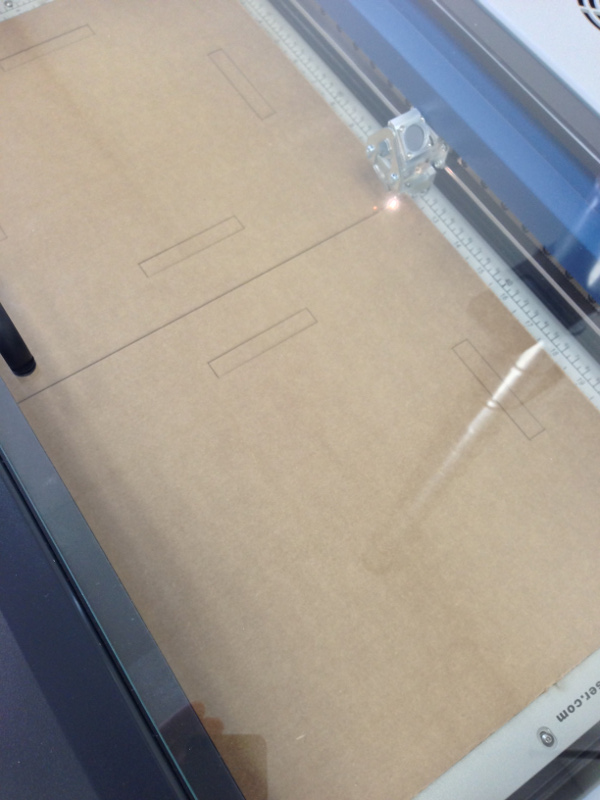

I decided to recreate the seat portion from my stool that I made in Week 9. I cut the framework out of cardboard using the laser and then added composite layers on top of the cardboard shell.

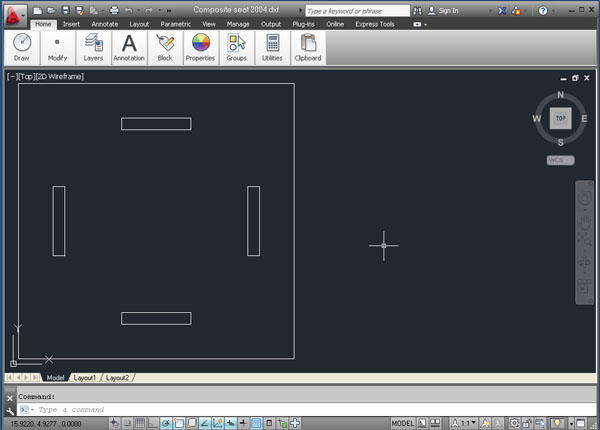

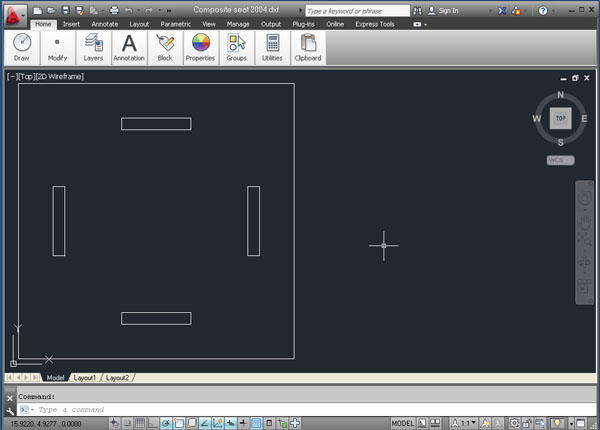

First I had to slightly modify the design to make it fit on the laser cutter - I could have done it by hand, but it only took a slight change in the outer border to make it fit cleanly.

I cut multiple layers so that I would have the proper thickness. While I was cutting this out on the laser, I also added the fabric underneath the cardboard so that I could have an accurately cut out piece of fabric.

I originally was going to add multiple layers of fabric to the composite, but it became too messy and I was afraid of wrinkles in my final result.

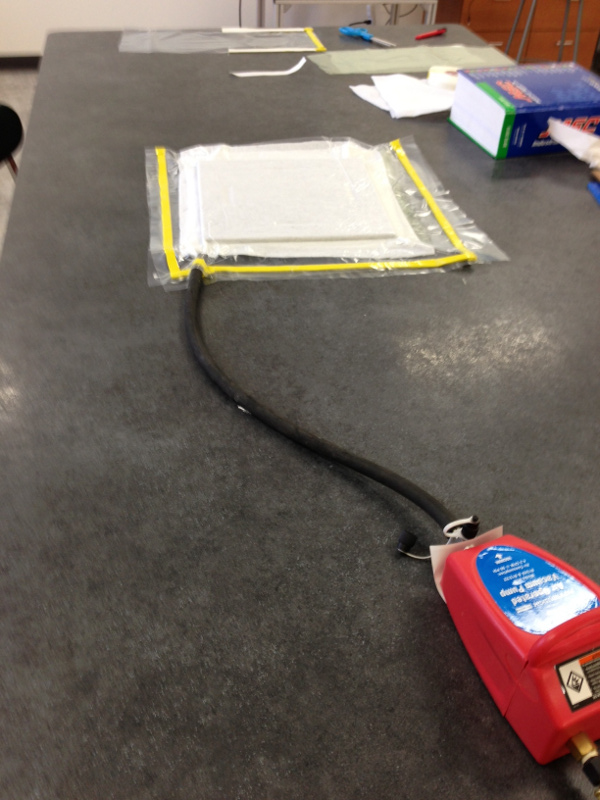

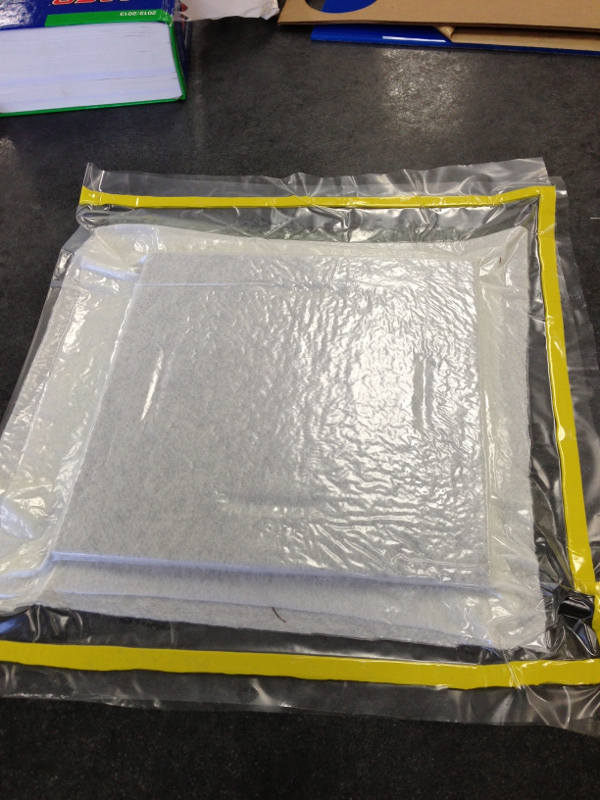

I created a sandwich of materials in preperation for the liquid layer. In the middle is the breather/release plastic, followed by the fabric that absorbs extra liquid and allows the air to be vented, followed by the airtight bag.

As it turned out, we did not have the proper fittings for the end of the hose that attached to the vacuum pump, but Fran had a hose that was the correct size and it worked fine.

The equipment did its job, and I soon had a nice seal.

I left the bag overnight and opened it up the next day.

Not bad, overall. I would like to have added more fabric to the top and sides, but it was a bit hard to work with and I was afraid of wrinkles and clumping. If I were to do it over again, I would take more care with the specific strips of fabric, making sure that they were large enough to stay put on the sides of the seat.