mechanical design, machine design

Automated Composter

Myself and Wendy are working with some students on this project, this is Wendy’s brainchild and everyone we talk to about it gets excited.

More about the project on Wendy’s site linked below.

http://academy.cba.mit.edu/2013/students/neale.wendy/May.html

“We have a lot of waste PLA from our up!+ Printers so I'd like to start working on a machine that will recycle that waste. We have looked at the machine on thingiverse that does that. First we'll make one that munches the plastic into useful small pieces, not pellets, but that sort of size. Probably using a hand operated meat grinder, and then mechanising that. Otherwise Bas has suggested that we work with a couple of the Fab Academicians from Japan, so we've started conversations about that too.

So we've been researching our ideas about the PLA, and talked to the gardener at our University and she is very supportive of us setting up an industrial composting system, where we can deal with that waste, the green waste and end up with compost she can use. At the moment we send away our green waste and buy compost. We also have a lot of paper towels from the bathrooms, our clean wood dust, and any number of other recyclables that end up in the rubbish when they could go into a composting system. We'll do a small test composter in the first instance and then work with the Sustainability Trust and the Council to develop it further.”

Below you can see some of the parts I have been work on.

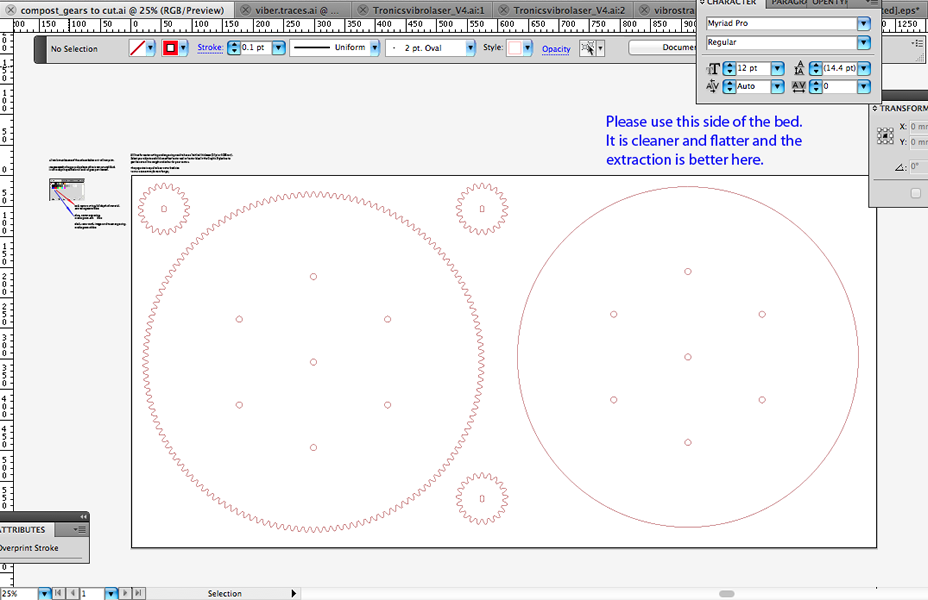

I have been working on the gears and the motor driver. We sourced a 12v Stepper motor from a old nissan truck, it is internally geared with lots of torque.

For the design of the gears I found a great online application here

http://woodgears.ca/gear_cutting/template.html it is a gear generator.

On OSX if you chose the option to print then save as PDF you get vector files for laser or CNC cutting. The problem I encounter with the application was the limit of size 400mm , my calculation was a 500mm diameter main gear for the project. Instead I used Vectorworks gear design function for wuch the same result to produce the small and large gears, which we cut out of acrylic on the laser cutter.

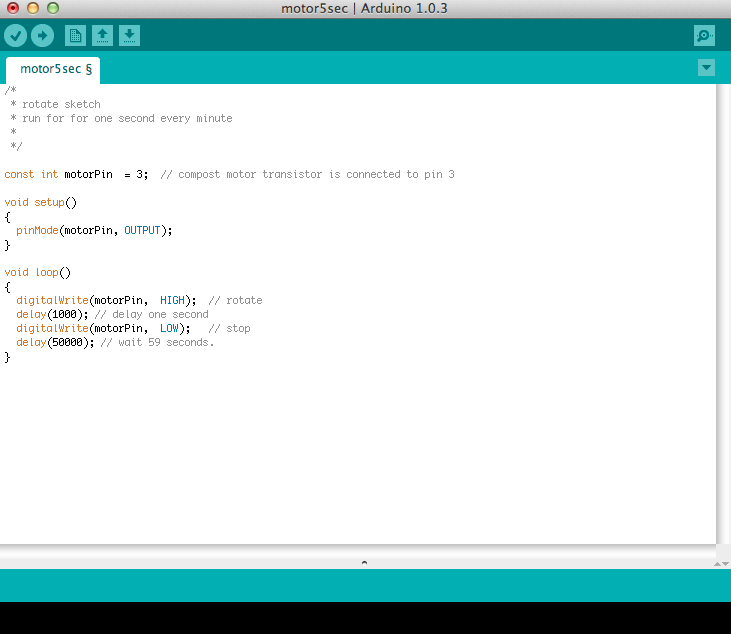

See the basic code below to get the motor turning for a set amount of time at intervals, I have the circuit working with a small motor, will need to take some time to upscale the voltage capacity of the circuit to 12v. We want to control rotation with both time and temperature, some more testing needed here.