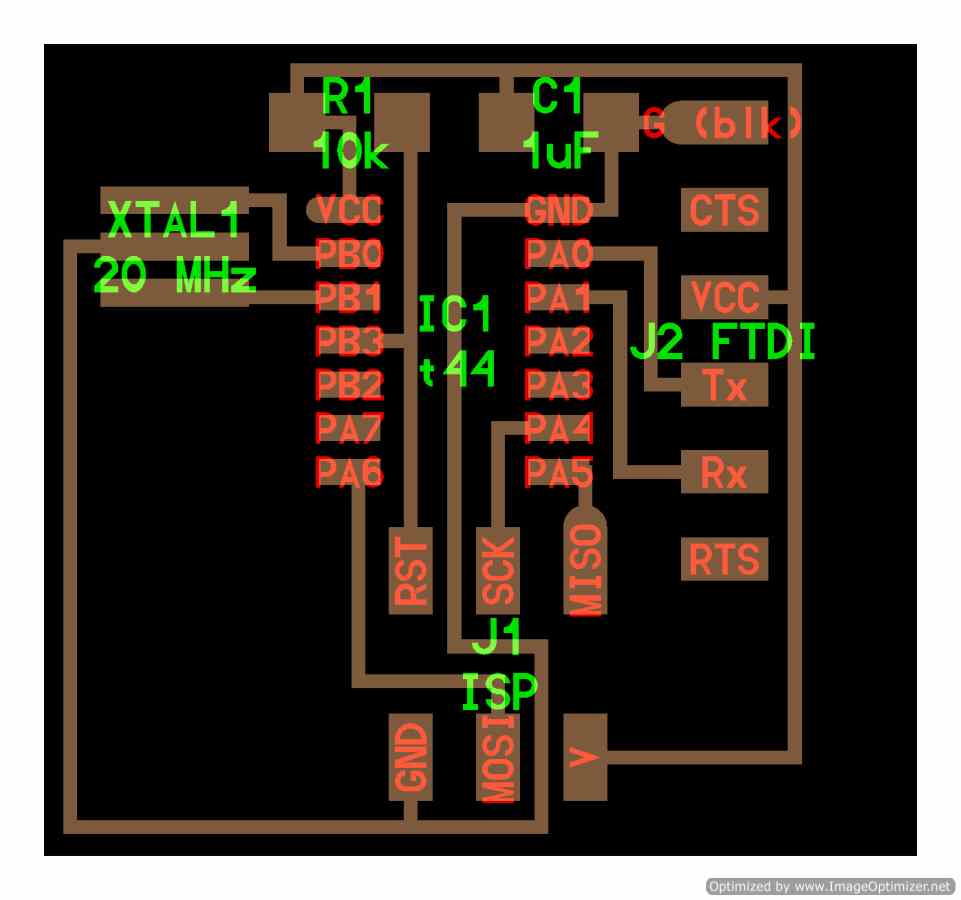

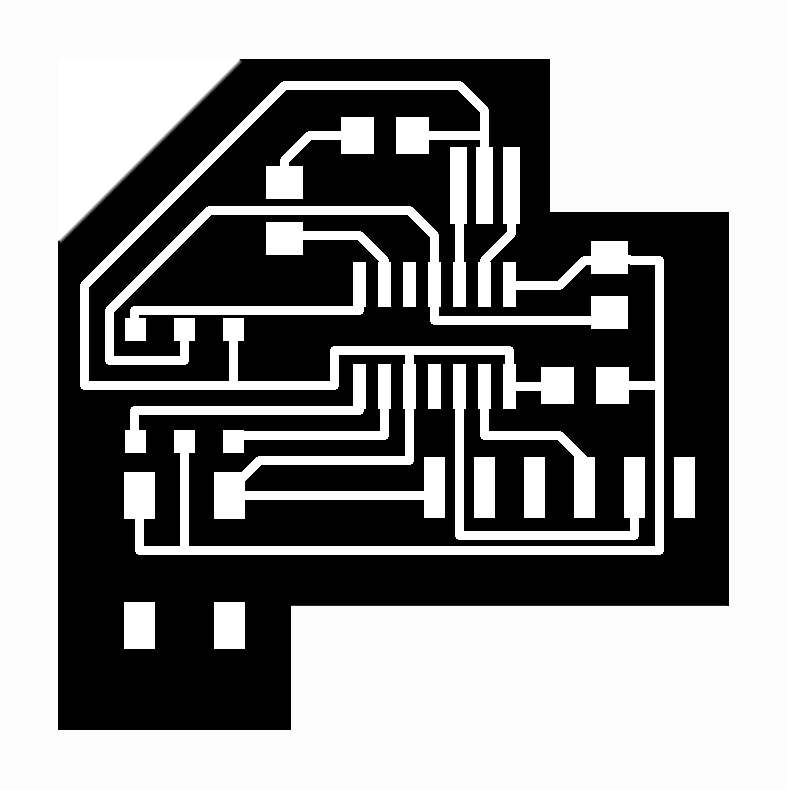

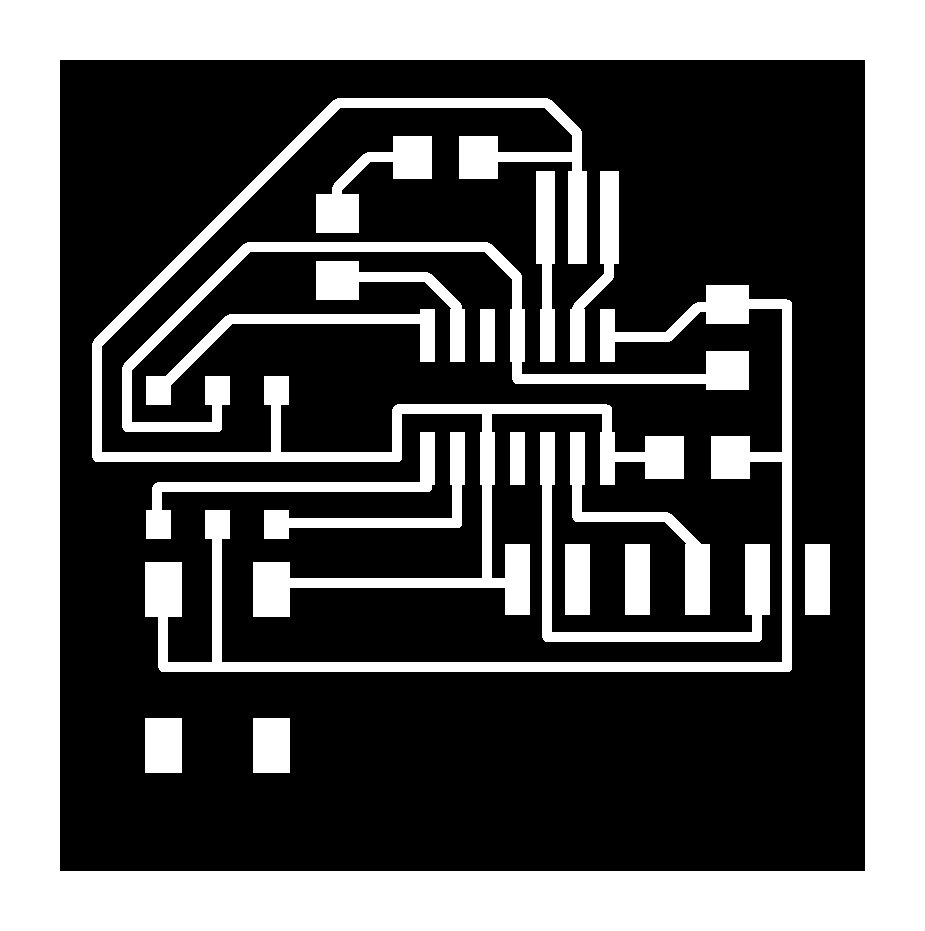

Schematic

-If

you have been following my blog, you would know I'm an

architect who has nothing to do with electronics at

all. it took

me sometime at the beginning it took me a while to

understand circuit basics

I started adding the components of the circuit one

Schematic Layout on EAGLE software following HELLO

board design

EAGLE the software, allows you to schematically connect

the components you have before converting this to a

board. the

assignment was to add a LED light and a switch to the

HELLO design, a friend advised to add resistors before

each of them

to control the flow of current

TIP

if you are new to EAGLE

there

TIP

if you are new to EAGLE

there

are tutorials, available

on you-tube are

helpful and easy.

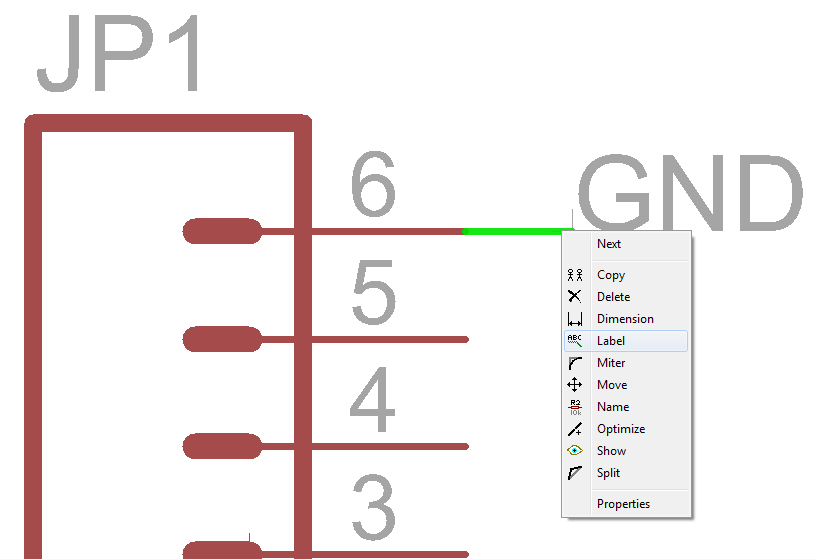

also during working

connections

might get confused as some

of them don't have names so make sure

to re-name and label them to notice

them easily

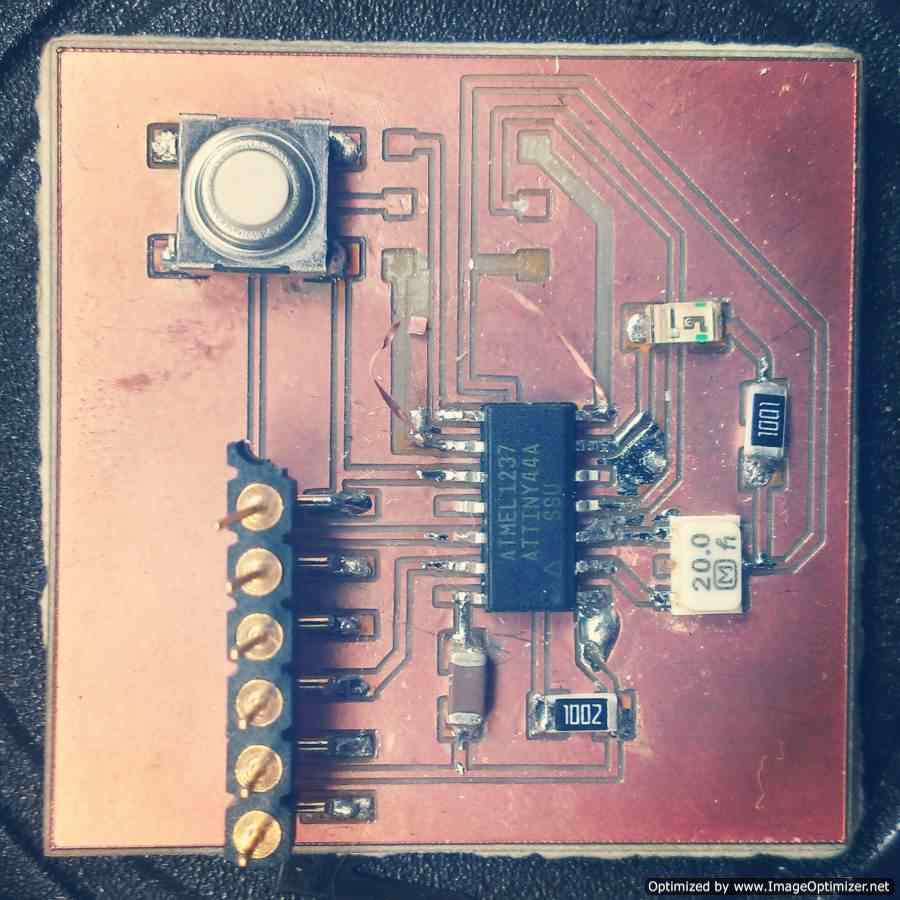

The board

When you convert the schematic

design to a board, it will give you the board with

proposal connections between the components you will

then have to replace them with what's called

"route" where current is supposed to flow

in the beginning it will be chaotic, all the

schematic lines are intersecting. You have to keep

rearranging it so as not to have connections

crossing each others.

Also to avoid having long connections

By clicking on the component the software highlights

all it connections, so you get to connect them one

by one. When you connect them the

schematic connection will disappear. REMEMBER

if you did any mistakes while

connecting you can always click on "rip up",

select the

route and it will convert it back to a schematic

connection

Also if any time you used the wrong component, you

can right click on it and click replace pick the new

one, it will replace it but with the

same connections the previous had, so that you don't

have to do them all over again

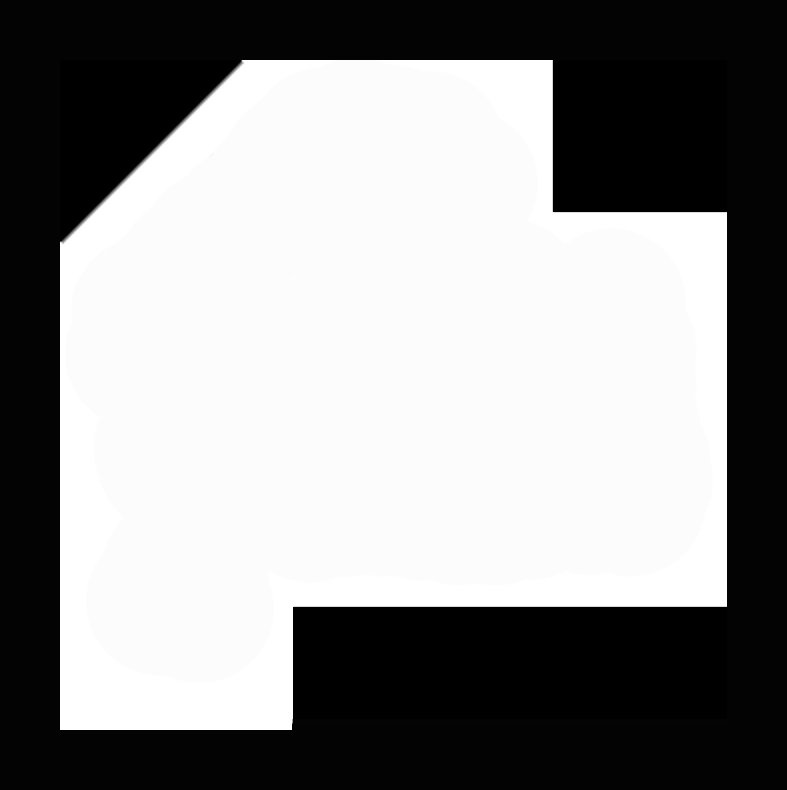

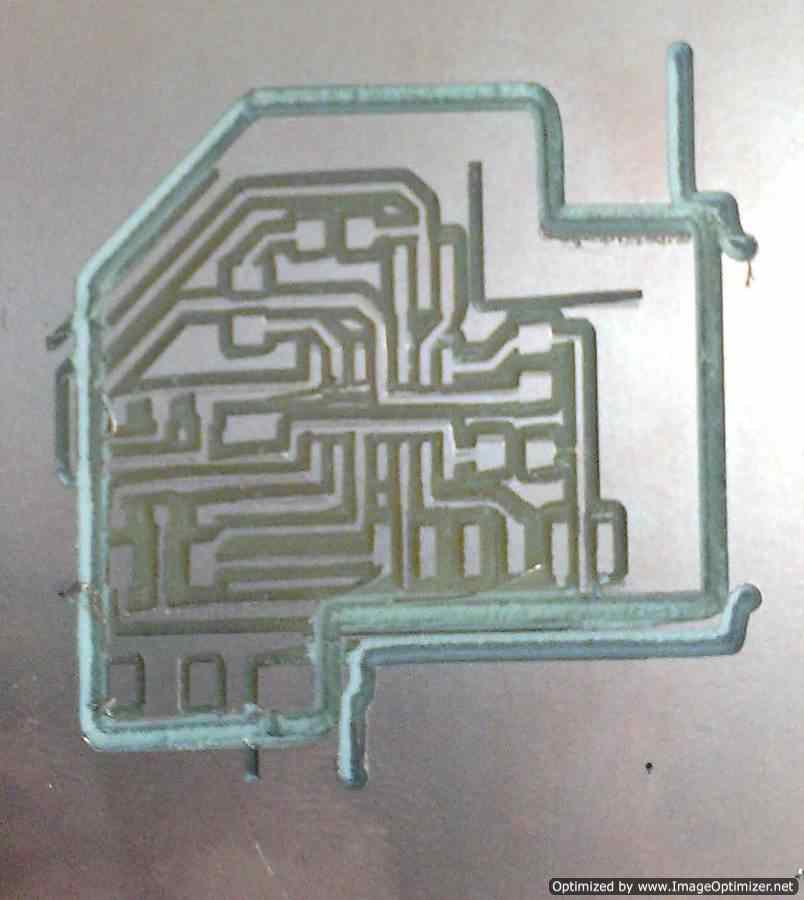

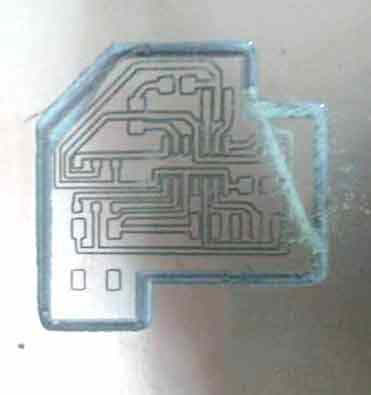

Saving &

Editing

After that go

ahead and save only the top

layer of your design for the

circuit and the dimension

layer for the border as a PNG

image then

start editing the outer

boarder as you wish

for me i used Photoshop its

easier, after i finished

designed the outline i stroke

the boundary with 60PX. Now

its ready for the milling

machine

ERROR

make

sure both

ERROR

make

sure both

PNG'S have the

same

(0,0,)

coordinates

otherwise it

prints will

shift

And

out

of

no

where

i had to Redo all

the milling again, so i had a chance so simplify some

of the connections so as the outline,

honestly i don't know what happened to the milling

machine BUT you have to live with it

>Proposal

>Digital model

>Laser Cutting

>Electronic

production

>3D Scanning

& Printing

>Electronic

Design

>Molding & Casting

>Embedded programing

>Computer-controlled

machining

>Input devices

>Composites