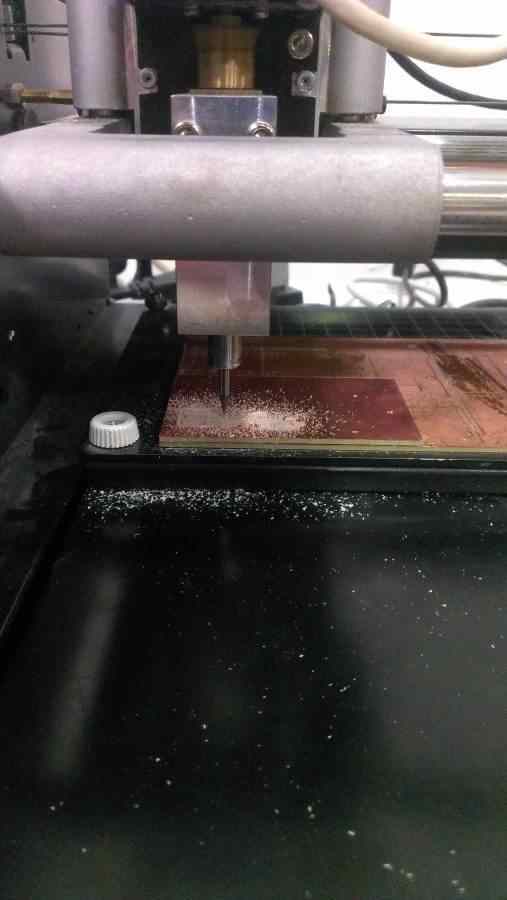

The Milling

-I

wanted it to be directly connected to the computer

through the USB stick

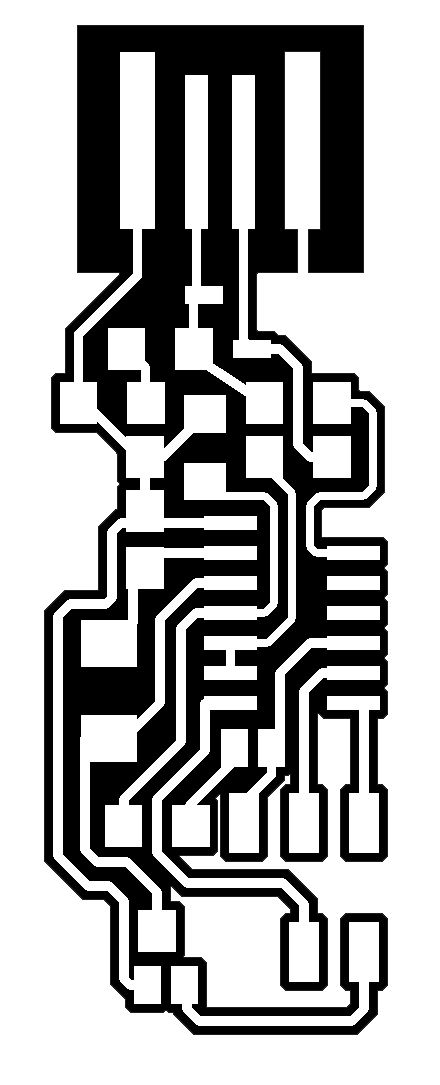

so i downloaded the JPG and the circuit drawing and

started milling the Grey scale

image you see on the milling machine

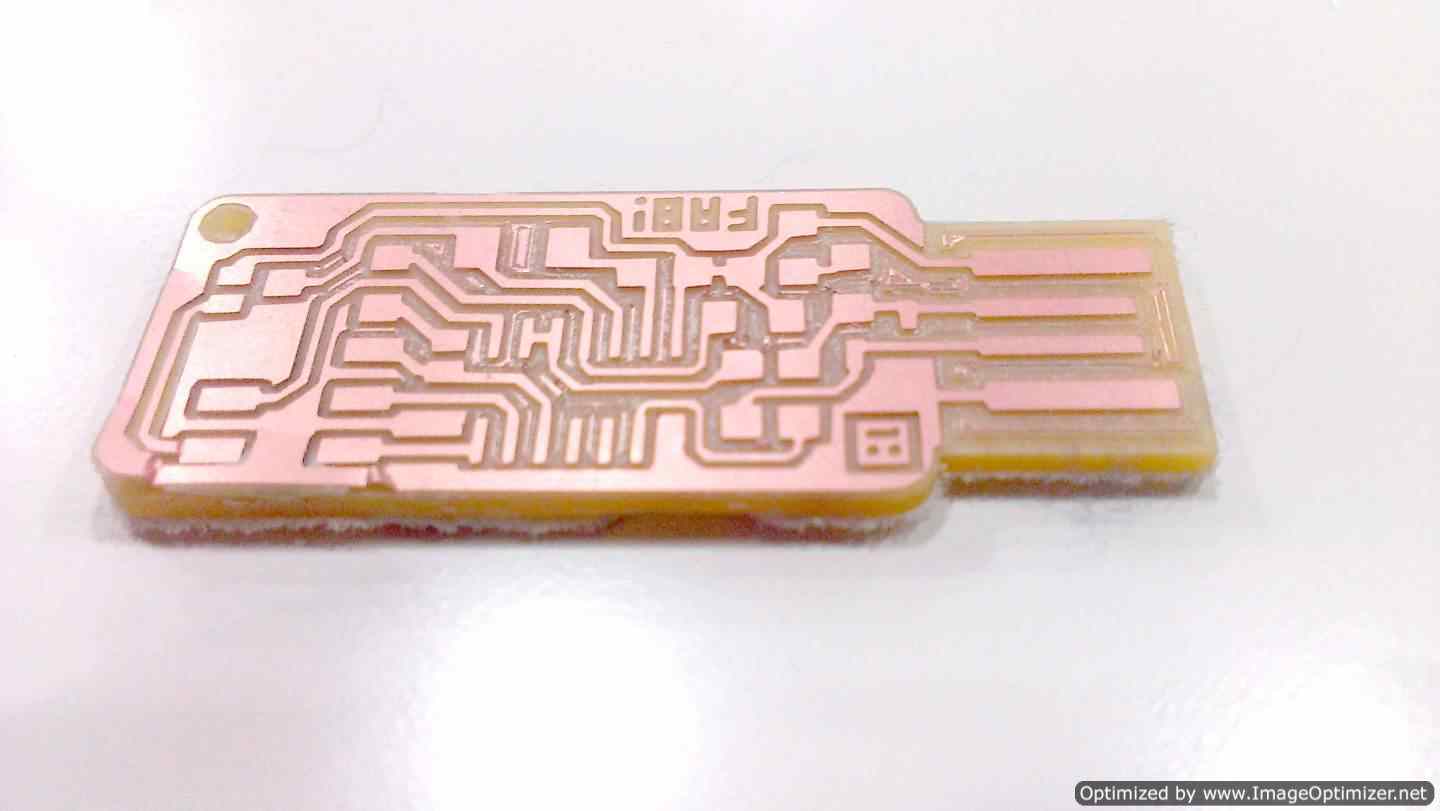

in this case, we used an acrylic board

covered with copper sheet, as the electrical

conductor material,as a body for the circuit.

then we used two different pins with

the machine the thick one is to cut the acrylic

board, and the thinner one is for milling

.the circuit itself

while changing the pins you have

to be careful not to fix the pin too low that it

breaks while milling, or too high that it don't mill

with

the proper depth. remember

that at any time if you doubted any thing about your

process, you can click VIEW it will pause the milling,

gets you your pad to view it, or adjust the pin's

height and then click view again to proceed

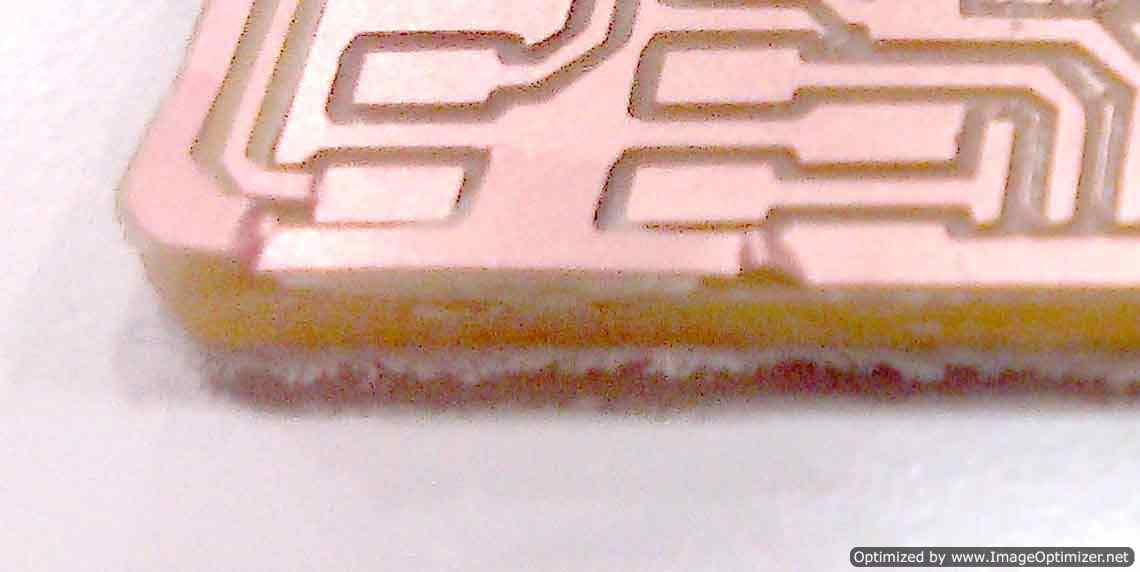

CAUTION

Be

careful while

removing

the

board after

milling,

if you did it

aggressively

it will ruin

the acrylic

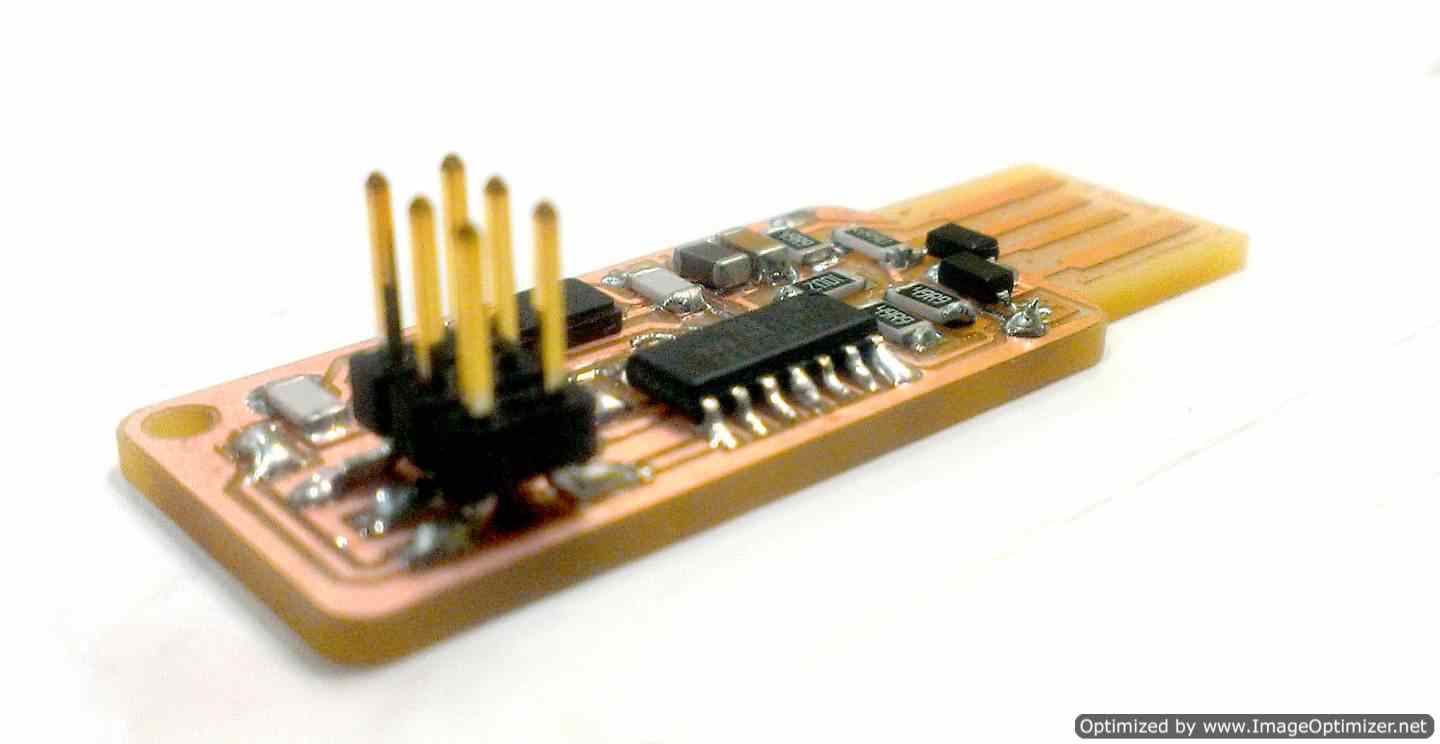

Assembly

-With Photoshop i merged

the circuit's image, with

the

schematic

and assembly drawing.

prepared all the

needed parts and

started

SOLDERING. while

soldering you have to

take care, you don't

heat the wire, you

heat the copper

surface first, then

after 3-4 seconds,

you touch the surface

with the wire. That's

when a little part

will melt. you then

remove the wire and

attract the liquid to

the hot point

before it dries.

-After finishing

you have to make

sure the

soldering

connected the

electrical part

(resistors,

diodes...etc) to

the copper

surface,

not just

physically but

also

electrically, so

you test it with

the

multimeter, if

it made sound,

then the

electricity can

successively

run through,

-

While soldering,

some parts has a

direction,

others don't.

Those who has,

has to be place

exactly with the

direction other

wise they

wont run the

current.

-Sometimes (in

my case) you

need jumpers

between copper

surfaces to

allow the

current between

them. you can do

it in three

ways,

First you can

just add little

part of soldered

liquid between

them, Second way

is to add a

pieces of

uncovered wire,

Third way is to

add a 0 resistor

it will let

current pass

through both

lines without

any resistance

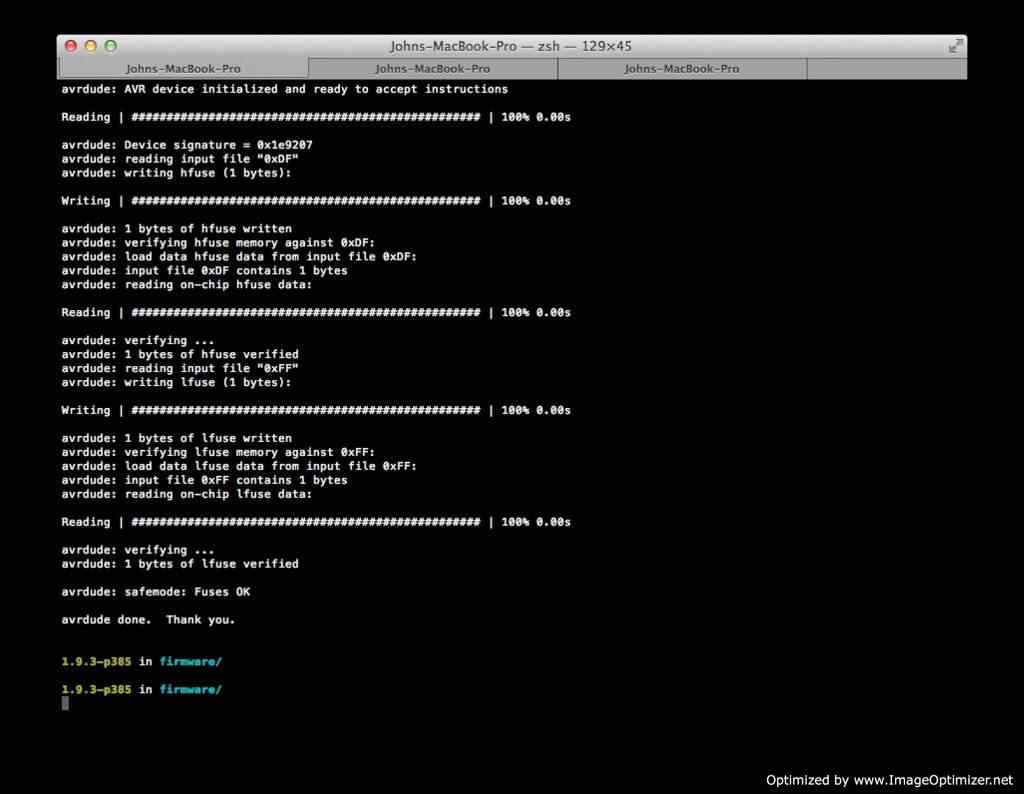

Computing !

-when your

soldering is

done, and

after making

sure with the

multimeter

that the

current can

run through,

you start

programing

with the USBtiny

Programer with

AVRDUDE & GCC you can easily program it !

THIS

GREEN LIGHT

MEANS

YOU

ARE

SAFE

NOW !!

>Proposal

>Digital model

>Laser Cutting

>Electronic

production

>3D Scanning

& Printing

>Electronic Design

>Molding & Casting

>Embedded programing

>Computer-controlled

machining

>Input devices

>Composites