-This week i designed

a table out of recycled material got

them from the trash on the heavy

garbage collection day. I fought for a

heavy

MDF sheet, which didn't suit my first

design, the material was too heavy for

it so i had to change the design to

this one.

i started the model in RHINO4.0

designing the layout of the mass. Then

with the help of 123D make i managed

to slice it into interlocking

layers.

With 123D Make i

managed to slice the mass into 4 horizontal layer which

acts as shelves in my design and two vertical ones which

will be the

supporters. You can rotate the slices or move them on

the 123D make as u wish till your satisfied with the

design, you can also control their

count and control the spacing distance between them if

needed

After that i exported the 123D proposal as a DXF i

edited the layout outline of the layers to make the mass

more dynamic, this step is only for

the design in other words i didn't need it, i went for

it only for the final looking mass

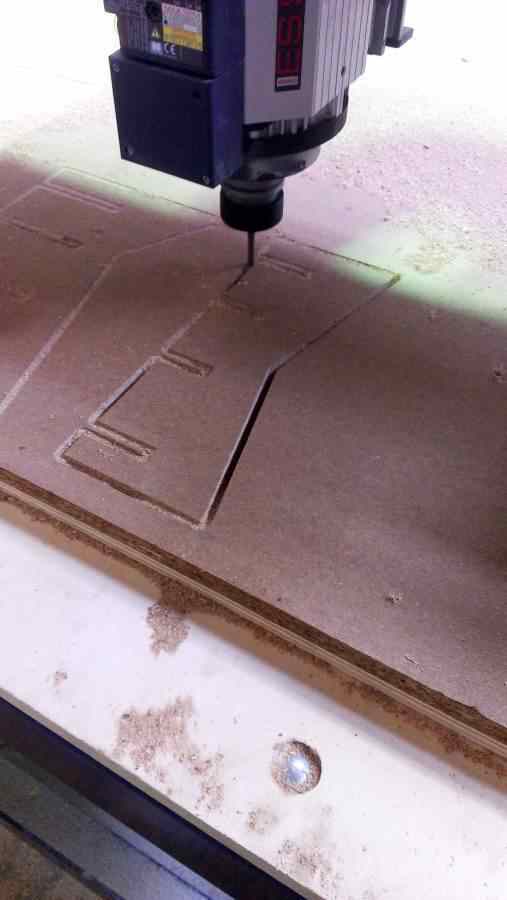

After that came the

machine calibration. Since its a milling machine so it

works with the basics. you have to calibrate XYZ

according to

your file where both the X,Y done manually with

the left and right buttons of the computer while in Z

the machine has to calibrate it

itself using a metal sheet and a sensor by placing this

pad below the pin it keeps on going down till the sensor

feels the pad and it stops,

after that it automatically subtracts the pad's

thickness from the Z calibration. you also get to choose

this to be the Z above or below your

surface it's your call while celebrating

Also choose the suitable pin according to your design

(smooth or edgy/thin or bold) while milling the machine

mill in layers each is deeper

which you previously set while the calibration, one

option this machine does is that it can drill though a

slope which you also previously set it

The machine moves in three types of motion INSIDE

OUT, OUTSIDE IN or ON THE LINE. you have to

separate your design lines into consideration

to that order, also into consideration to the pin's

radius so as not to eat much from your design

CALIBRATION

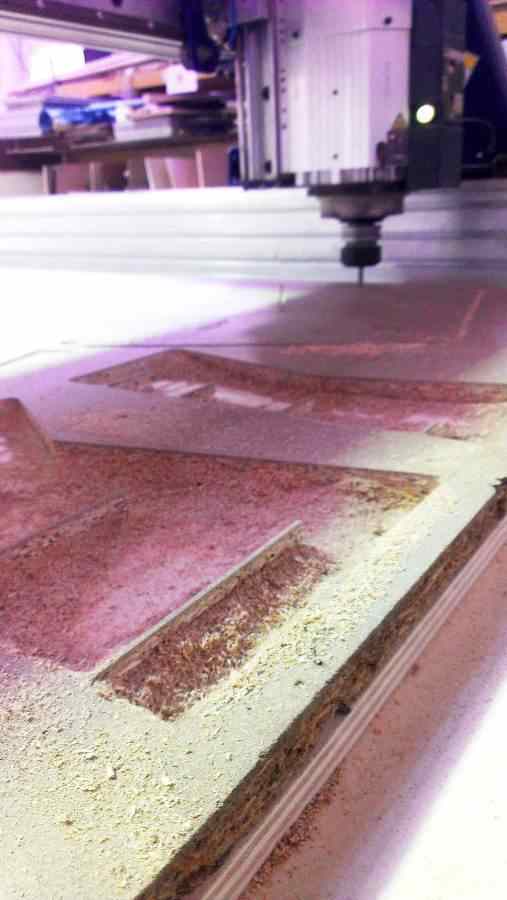

You will use screws to hold the pad while milling it

has to be in certain places where the

machine will not move through while milling your

design because THE MACHINE CAN NOT

DRILL THROUGH METAL BODIES, and in

case the pin met a metal body while moving BOOM

the machine will crash so MAKE SURE

YOUR BOARD IS CLEAN AND CLEAR OF ALL METAL

BODIES second thing the machine will drill

the inside out then the out side in respectively.

during the job you can accelerate the drilling

speed from the board on the side of the machine

you can also click on the RED button to stop the

job at anytime

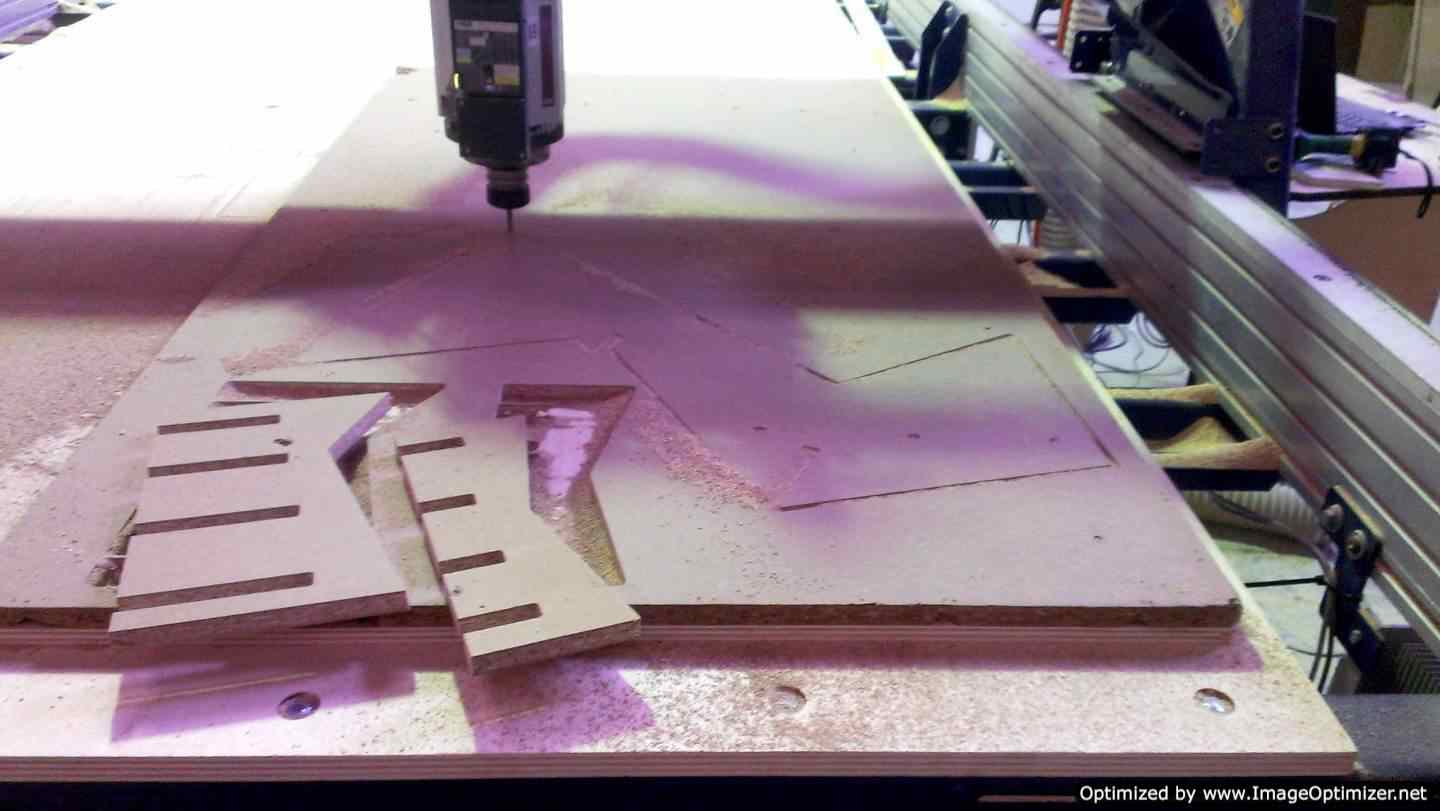

ERROR

The

machine wasn't cutting through although we did the Z

direction more than the material

thickness still it didn't cut through. i had to

stop the design and re-measure my board more

than once from different sides and edges and

found out that the board wasn't flat i took average

of the heights and changed the slots thickness in the

design so as the depth of the drilling.

AS LONG AS YOU HAVE A SACRIFICE MATERIAL SHEET

below your material it's okay to go 3

to 4 mm more than your material's depth so as to get a

clean cut and avoid not cutting through jobs

After that the job went just fine, TIP don't remove the parts while the

machine is working it's better to wait till the end

of the

job it helps balancing

the material while working

After

finishing un-drill the fixing screws then remove your

board clean all the mess, the start cleaning your

parts edges before

the assembly

>Proposal

>Digital model

>Laser Cutting

>Electronic

production

>3D Scanning

& Printing

>Electronic Design

>Molding & Casting

>Embedded programing

>Computer

controlled

machining

>Input devices

>Composites