For this week’s assignment I am expected to:

1. 3D Scan an object or body and 3D print it2. Or 3D Scan an object and 3D print another object.

I choose to go with the first one.

In order to implement this exercise I did the following things as a preparation:

1. I choose to work with xbox 360 Kinect

2. I downloaded software called “Kscan 3D 1.0” software. Since I only manage to get the trial version and the version limits all kinds of exporting. I decided to change my software choice to “Skanect” http://skanect.manctl.com/ . On this software, even if you manage to download the trial version, you will gate a chance to export or share a 3D scan from the software. There are options you choose while using the software. There are settings for Body scanning, Object scanning and Room scanning.

3. Since I chose to scan a body, I get a cooperation from a chilled who was taking a fablab workshop for kids at our lab and our instructor Bereket nesh and managed to get a scan of the child as shown in the picture.

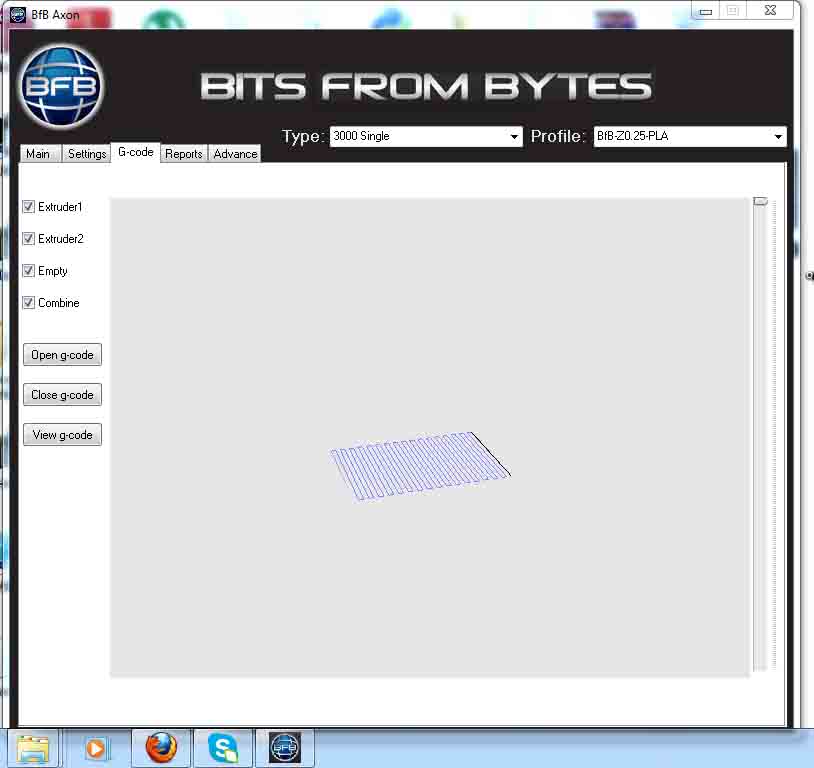

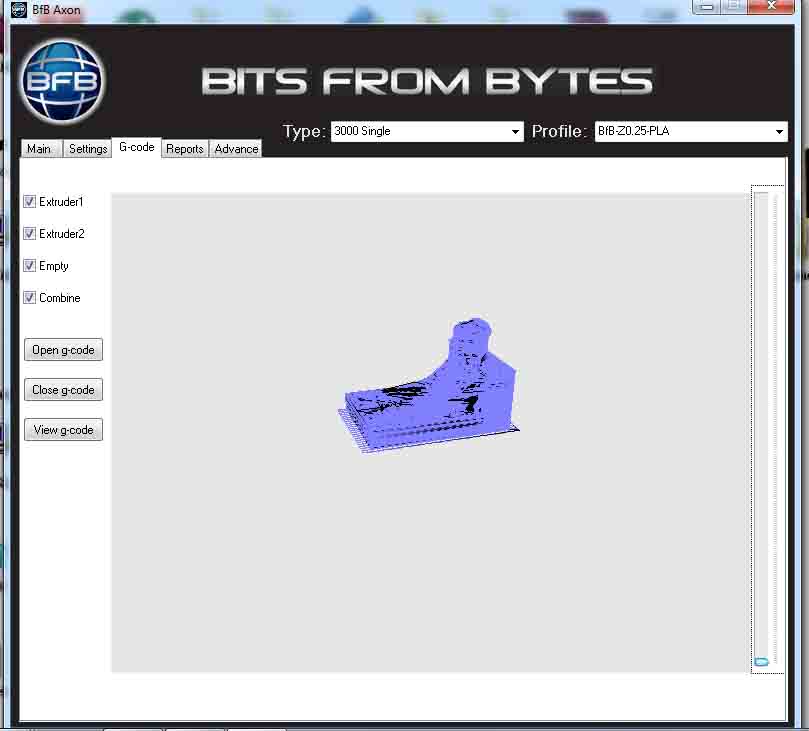

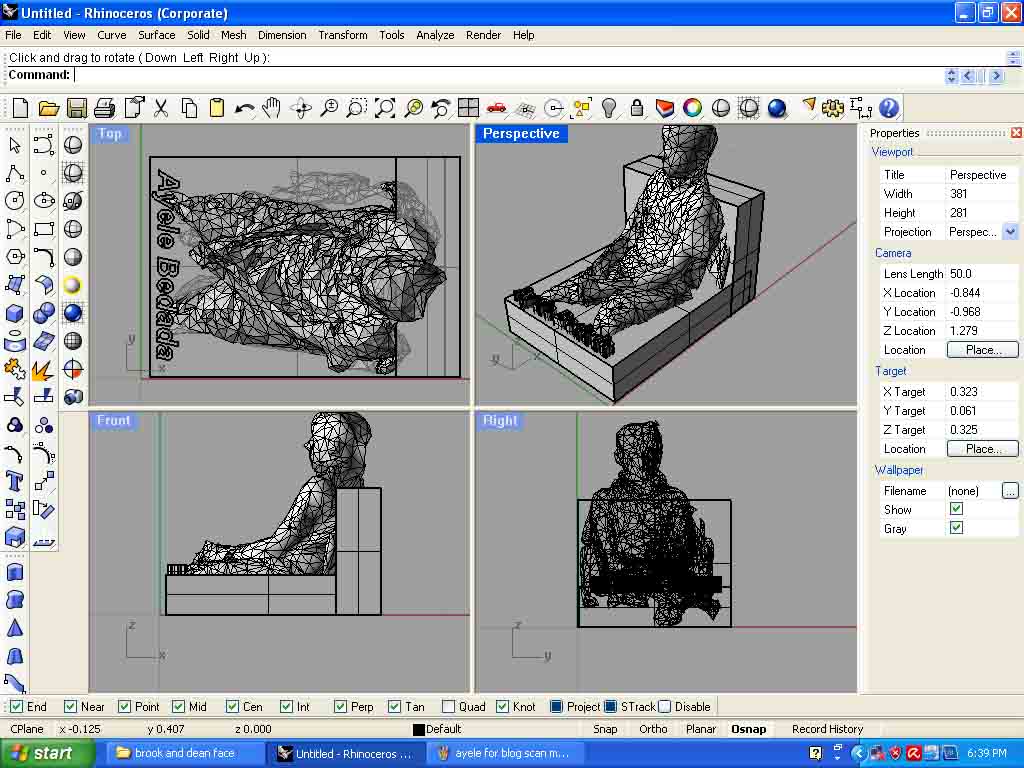

4. After the scanning is completed, I shared or exported a .ply file of the 3D scan to my computer and made a modification of the file on Rhinoceros. See the following picture.

5. After the modifications, I exported the 3D file in .stl format for the BFB. 3D printer.

6. The 3D printer we have at fablab addis is BFB 3D Torch Dual Head. I prepare .stl file for BFB axon.

7. After building my model on the bfb axon, I took the file on a flash card and started printing it on the BFB torch dual nose 3D printer.

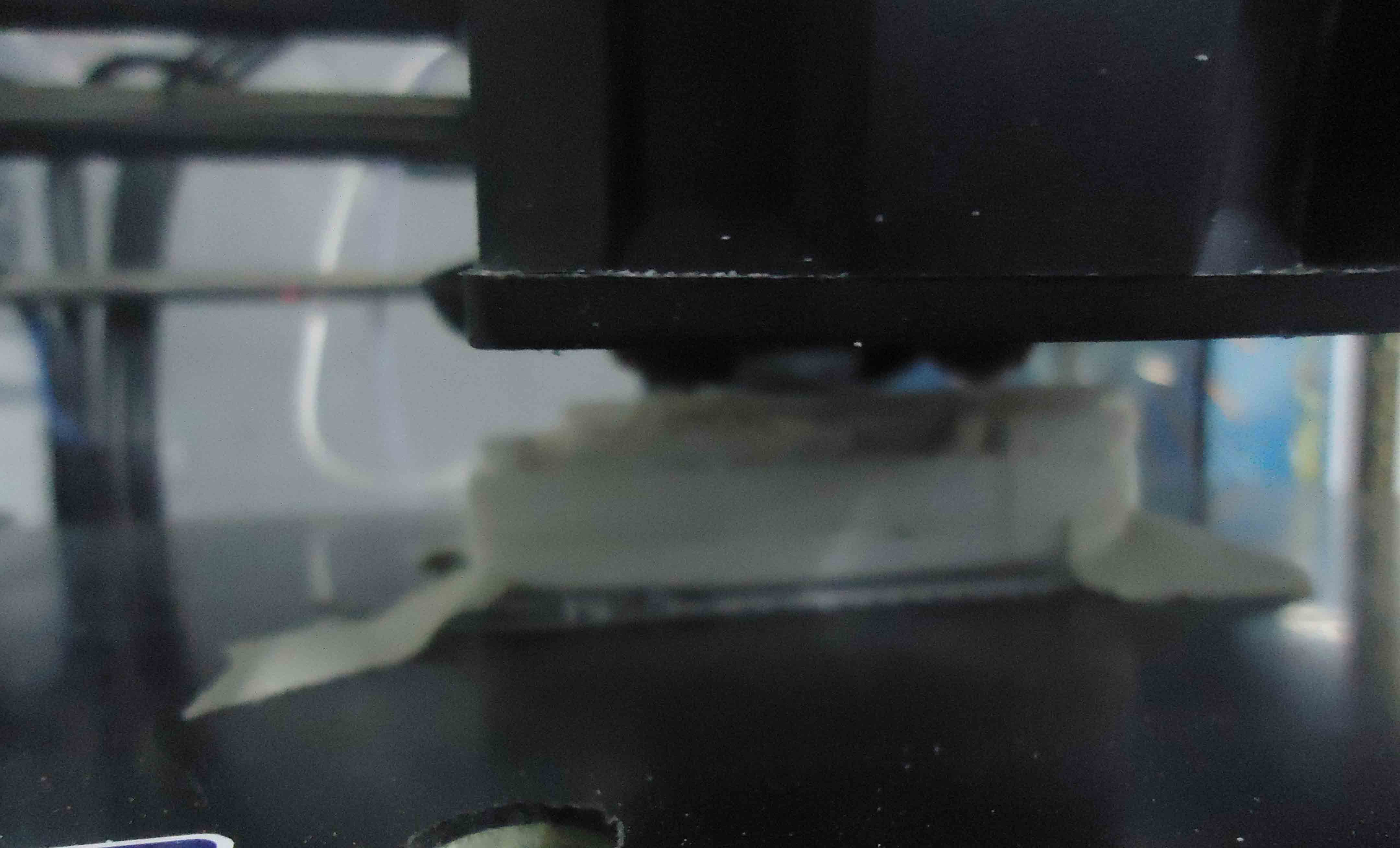

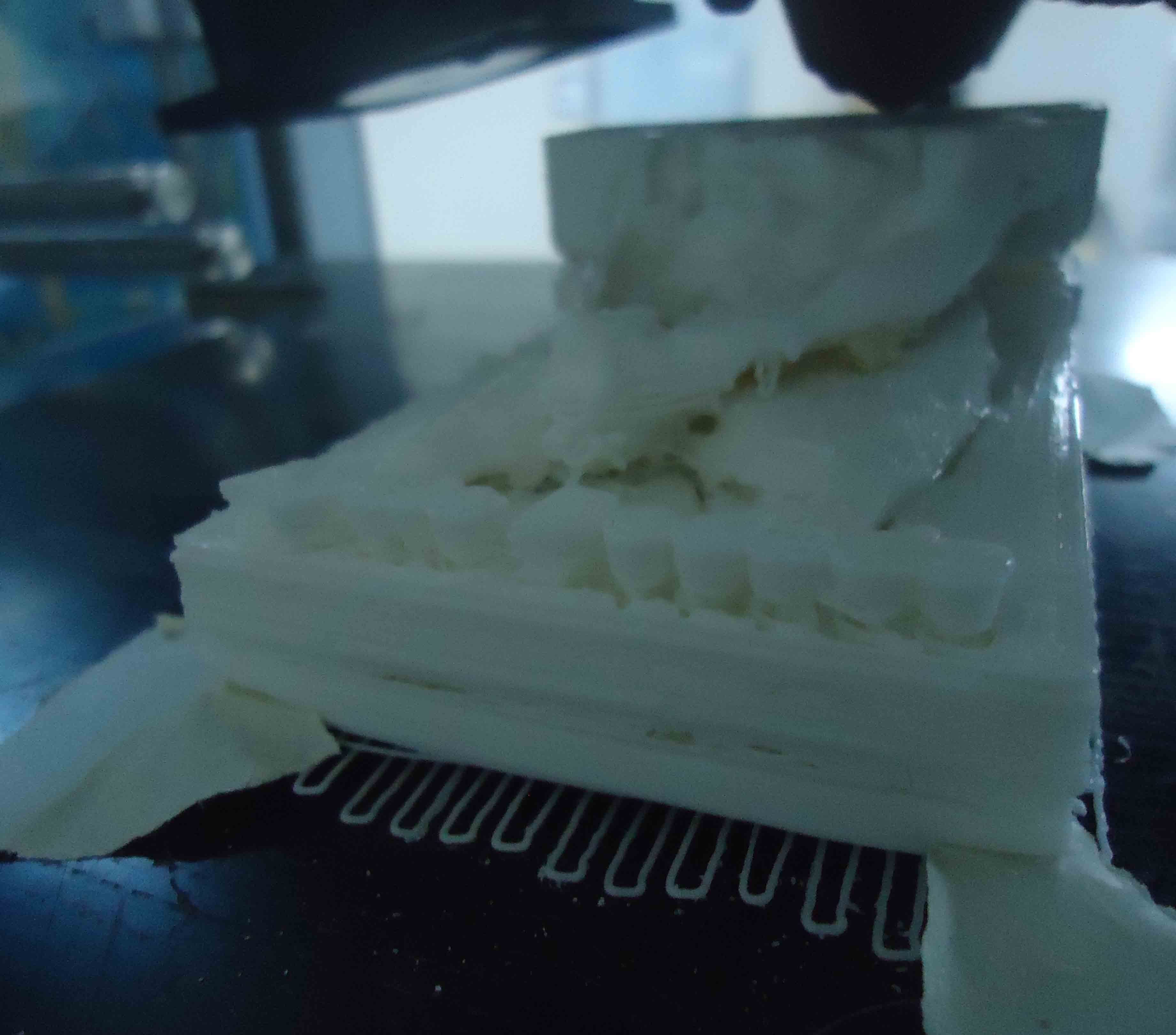

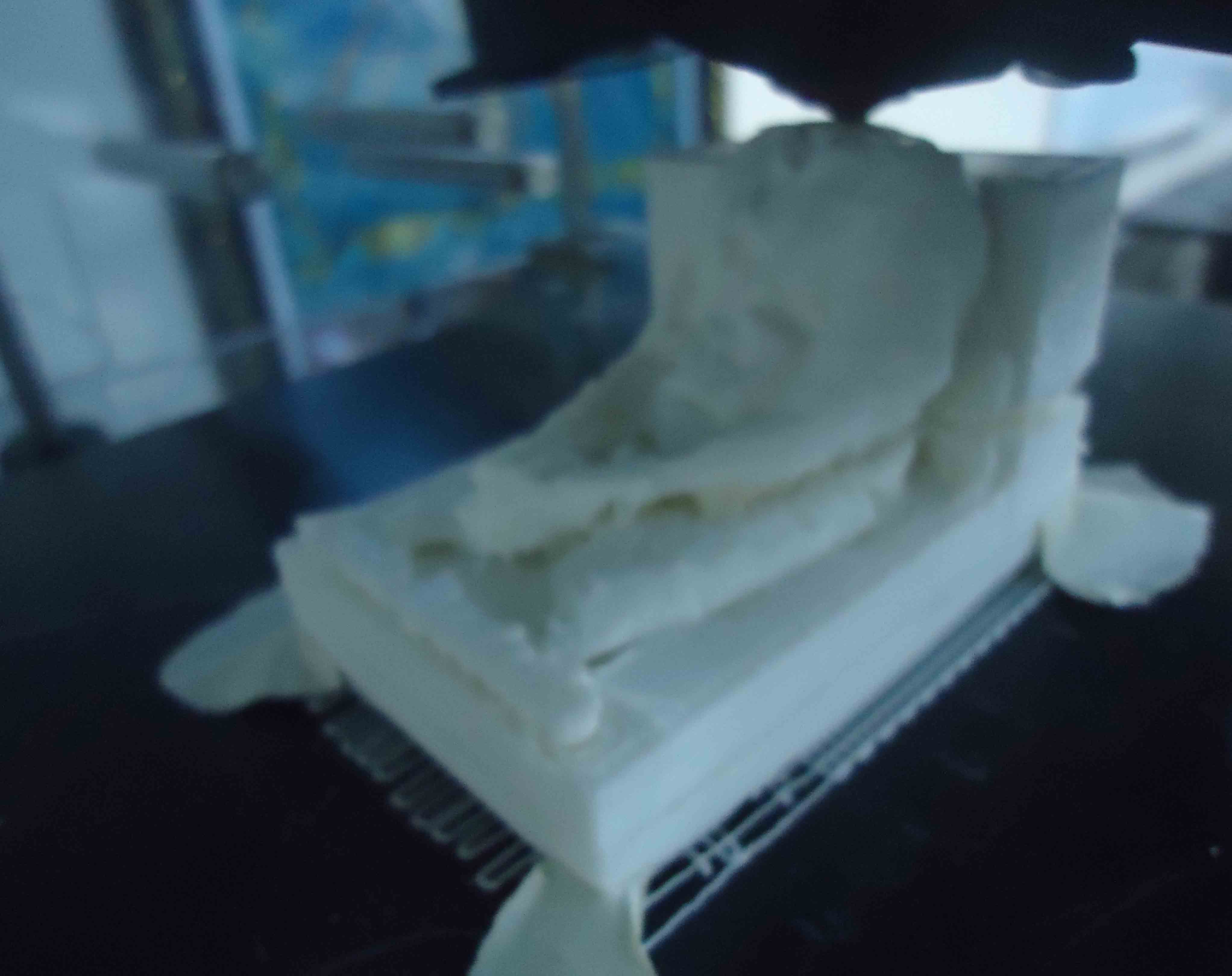

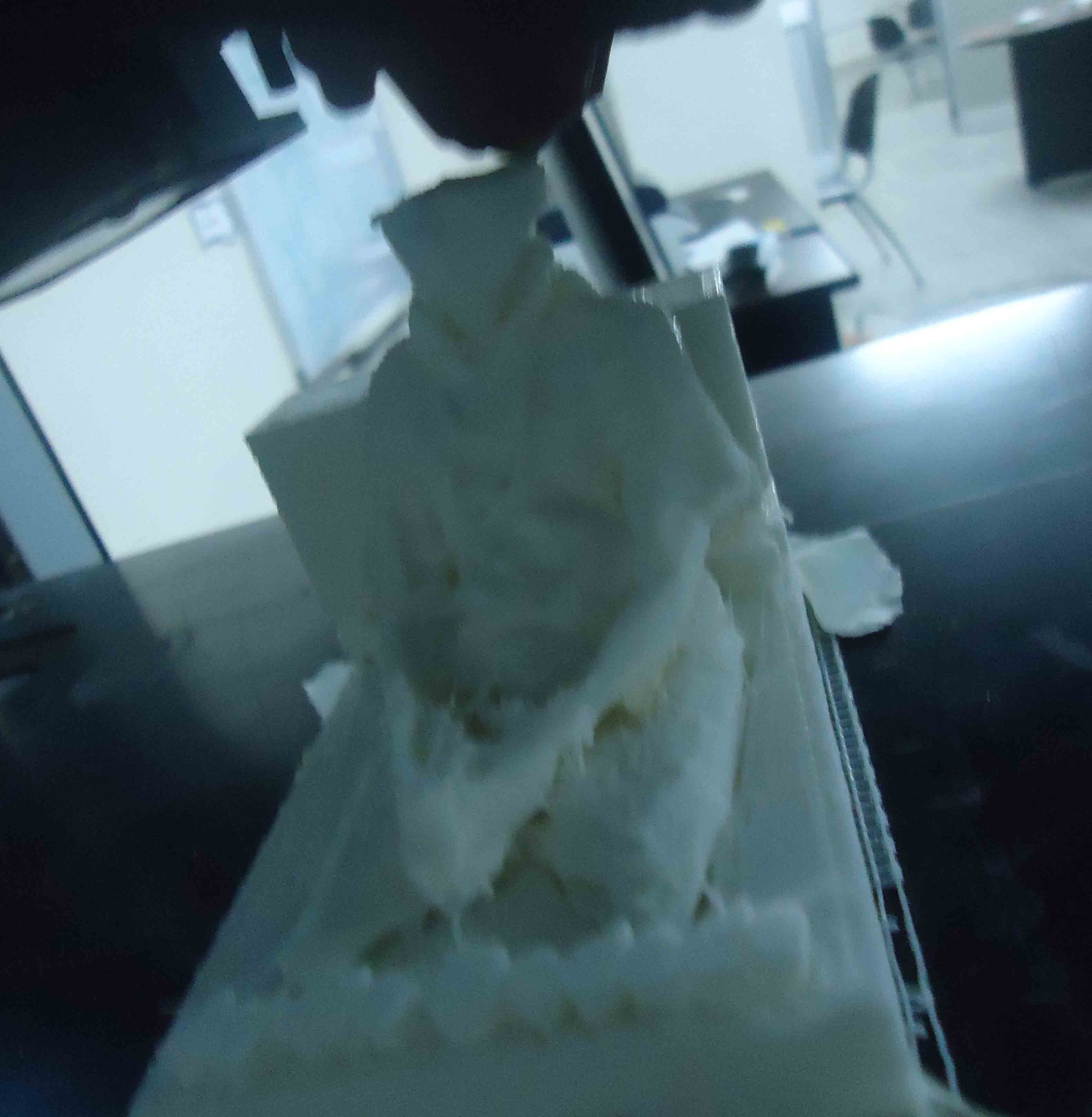

8. The printed out result looks like this:

Challenges

- The scanned models usually need further modification before printing. Getting a professional license for the software one is using might reduce the extra work one needs to put in to the modification

- On 3D bfb torch printer, sometimes once you already started printing the ongoing printed object might move. The object becomes concave from its bottom and around its edges the top surface will touch the nozzles. That is when it moves. There for one should find a way to make it stick permanently to the base.

In my case I used a masking tape plastered on the model and the base as shown on the pic - The BFB 3D torch dual nose 3d printer might sometimes stop pulling the material it is melting to make the printing in the middle of the print process. Therefore one needs to check the print process regularly. To increase the temperature, to replace material, to pause if there is a problem, etc.