Shopbot week!!!

Last summer I worked on the shopbot for almost 3 weeks. From before 8 in the morning until late in the evening. I loved it and cutted out more than 40 plates of wood. So this week sould be easy for me...

Yeah right. Never take somehting for granted. I had an idea to make a chair but changed that quite fast to a shelf. Not a boring one like the ones you find in IKEA but one you can play with.

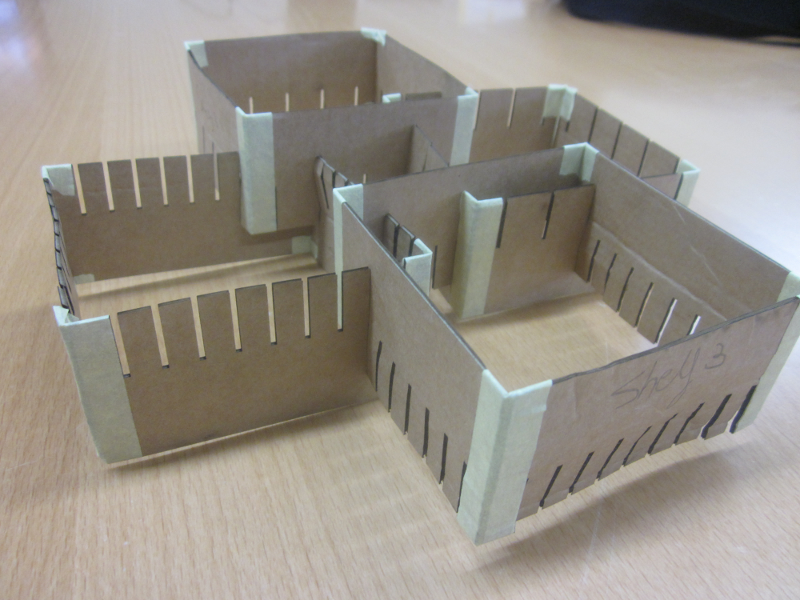

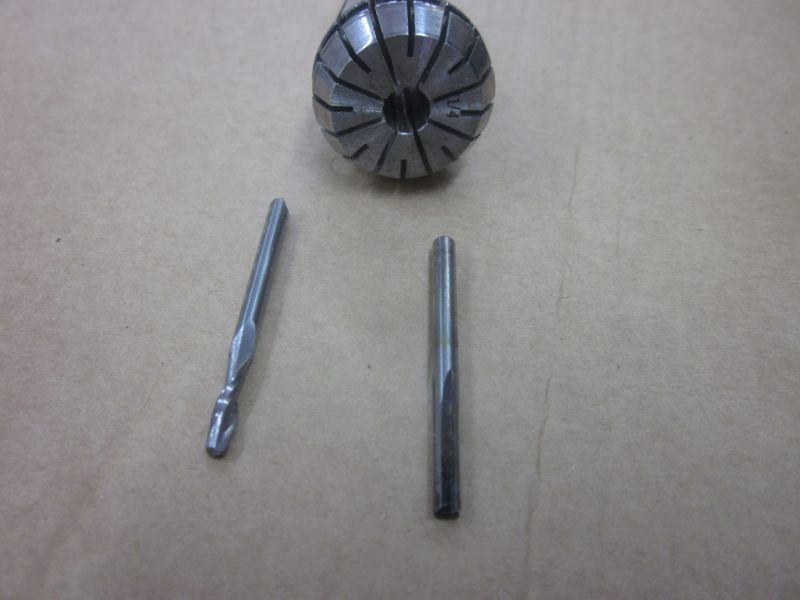

I've been spending my weekend making prototypes of of my idea in carboard. One, and another, and another one... I wasn't familiar with how deep the insicions had to be to make it fit. And then on monday, when you are with 2 in the lab; you want to mill it out and you figure out that none of the drils works, since that they are all thicker than 3mm and we didn't trust the very fine ones, they look so fragile for such a big machine. Another thing was that a lot of the mills weren't in their boxes anymore. So we could messure the thickness but we didn't know wich one was for wood or wich one for arcyl. The fine one looked far to fine for wood and, we did't have a part that fitted on it. I've told a friend and my mom about my idea, and they both like it, so I'll be making a small version for candles. But still, you worked on a design and it doesn't fit in the shopbot, and you start redesigning. Since you just want to finish the homework you go for a box.

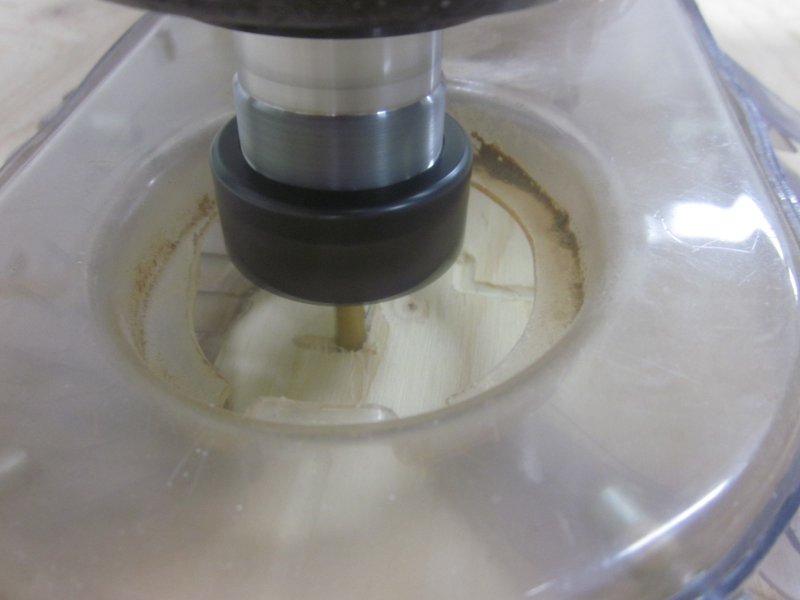

But even that didn't go without problems. 6 months of living my other life in Belgium made me forget how to opperate the machine. The shopbot didn't cut throug the material. A problem I've had last summer to. Frosti told me then that you alsways need to go a little bit deeper than the thickness of the material. So I did, but without result. I've deseided to let the file finish, see how much deeper I should have gone and then changed from cutting dept 1cm to 1.3 cm and starting at a depth of 9. A bad desicion so it looked like. Because now it cutted to deep.

On the left side it didn't cut totaly through and on the right side my mistake between cm and mm.

I had one file left and putting it on 12 there didn't cut throug neighter, so I had to let it go for one round extra to cut through the material. After kicking it out of the wood and sandpapering it it looked quiete ok.

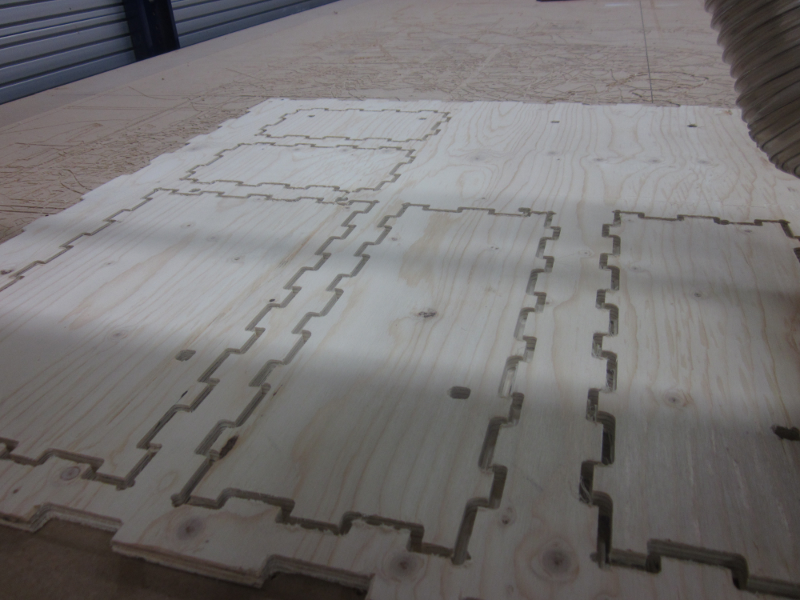

By then I already fixed the other plates of the box to eachother. Since the pressfit didn't work, I've used some screws. What happend in the shopbot was that whe the plate was cut loose, the shopbot still had to go a few more rounds. The plate was loose and everytime the shopbot touched the plate from my box, I lost some of the blocks from the pressfit. So maybe, when I saw the first time what the outlines would be from the box, I've could have put one or two screws in it so it wouldn't move.

What I said about the outlines. I mixed cm and mm the first time. I would say it was a good mistake, since I could really see how it was going to cut out everything. I just didn't use it to put the screws in.

What I learned this week is that you have working on a shopbot and working on a shopbot. The first working on a shopbot was like last sumer. Frosti took the right drill, fixed the program and I was just cutting it out. Plate after plate after plate without changing anything. And when I did break a bit, I called him and he changed it. It was good though, I learned working with an electric screwdriver but nothing more than that and to import files and make the machine run. The second working on a shopbot is like this week. Having to figure out everything yourself and fall down. Because learning goes with standing up and falling down. And I can say that I made an example on how it it not supposed to be.

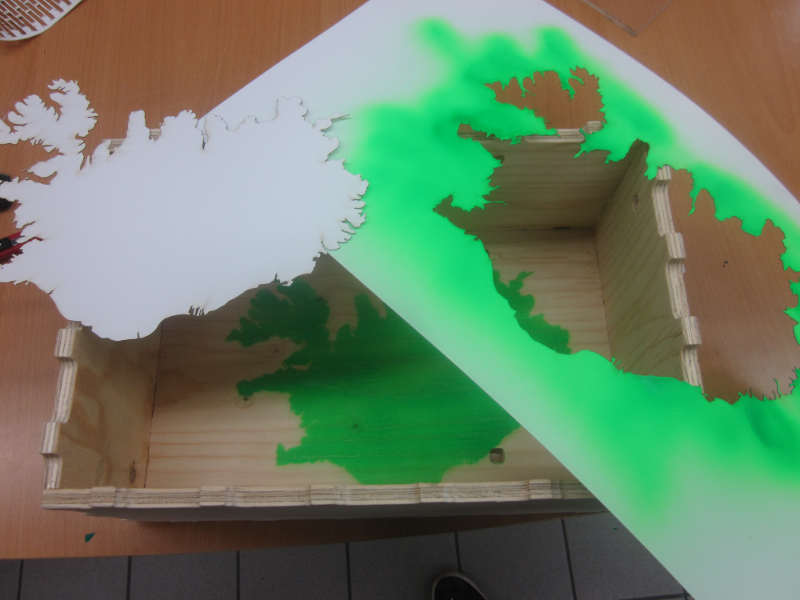

Because making a box looks probably easy to most of you, I stated working with something more familiar: stancils. And since I've always wanted to have a box to put all my Icelandic stuff in (from Icelandic christmasscards, to the booklets from a play I was itn, to a test from geography that I made here as an exchange student), I made a stencil from Iceland and put the grafity in the box (since I don't have a top because it was to big to fit on the other parts).

On tuesday Frosti came in and checked on the homeworks. He could anwer my question about 'when do you know wich dril you use?' It depends on the material, de speed, what it has to do... It depends on a lot of things. And of course you need to know wich bit is wich since they are not marked in our lab. He also told me that sometimes on the box they say that it's a 5 mm bit but when you really start cutting, it only is 4,7mm. To know that you need to do test lines. Something else that we noticed was that there were wrong calculations in the box. So that it couldn't fit.

This weekend I'll try to remake the box, or a new design so that atleast I can show a good result on the webbage.

to be continued