This week stands for working on our final project. And so I did. I've learned a lot. A lot of things that might be logic for other people. And I made progress. Not as much as I wanted though. But my problem solving is getting better and faster.

As said before, I'm making an educational model of automata. Wich basicly means that everything will be visible.

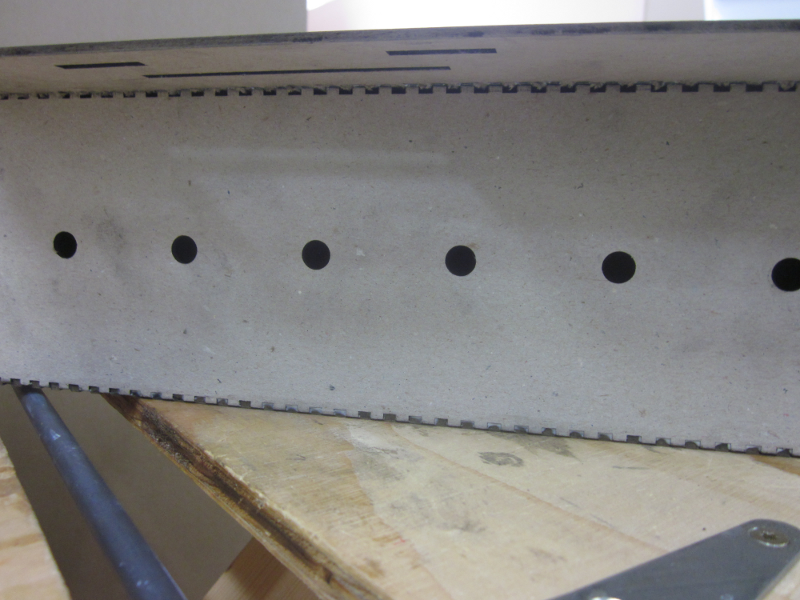

I have a box in wich there are 7 holes to each side. Inside there are gears connected to each other that will take the movement on them.

Every gear will be connected to a kind of automata. I've stayed with the basics since this is 1) new for me and 2) new for the kids that might be teached with it.

On top of the box there are letters, figures, boats... moving. Though with the lack of time that I have, I'll keep it simple and use a 5 - 7 letter word.

I'm thinking about making them in the shopbot, where all the rest is done in the lasercutter.

One of the problems that I had was that the gears in the box were the same seize as the ones outside of the box wich means that they were crashing into each other. A solution could be to change the seize of the gears inside. Or to do like I'm going to do now and and put them on two rows.

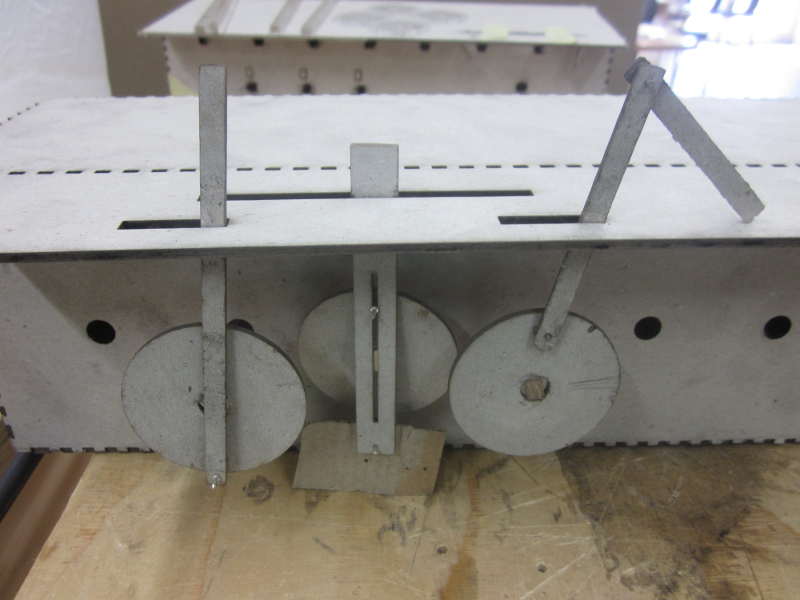

How it will look like with the 2 rows.

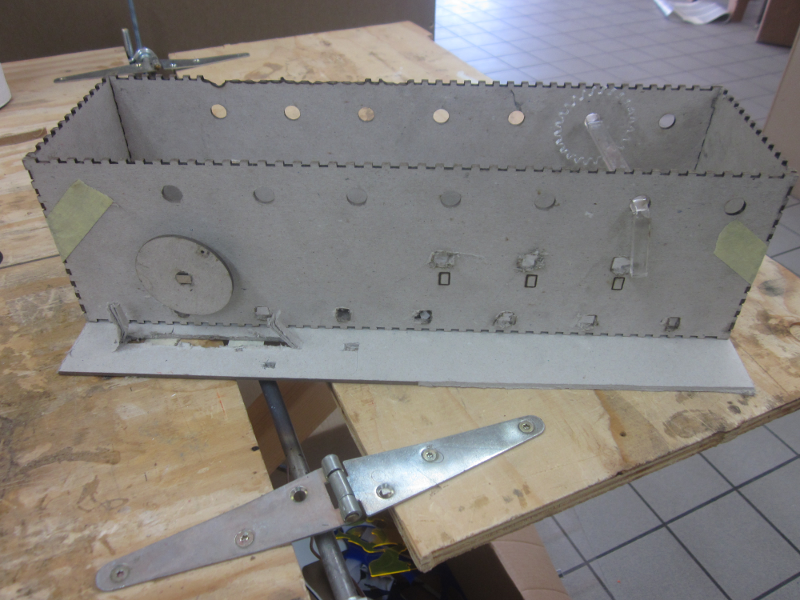

The back of the box. The ends will be bowed so they can't move while working.

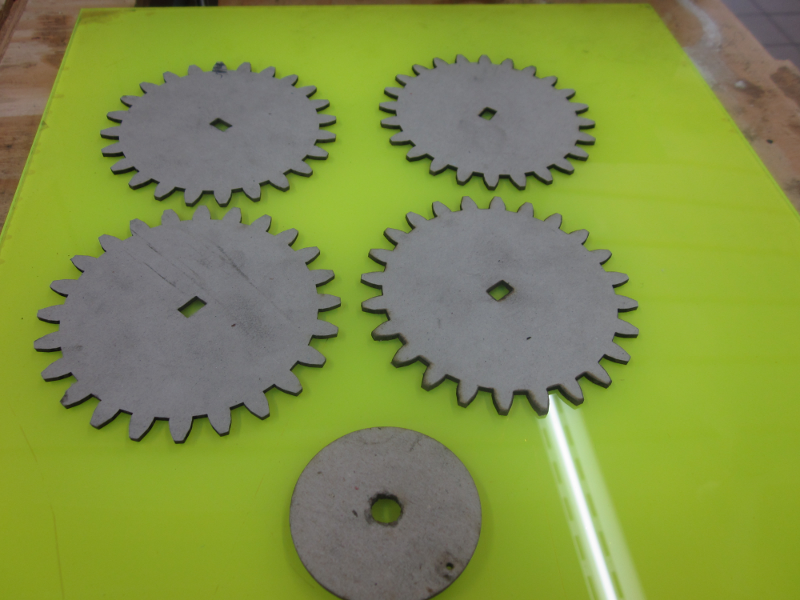

The new, bigger gears. With an old seized one next to it.

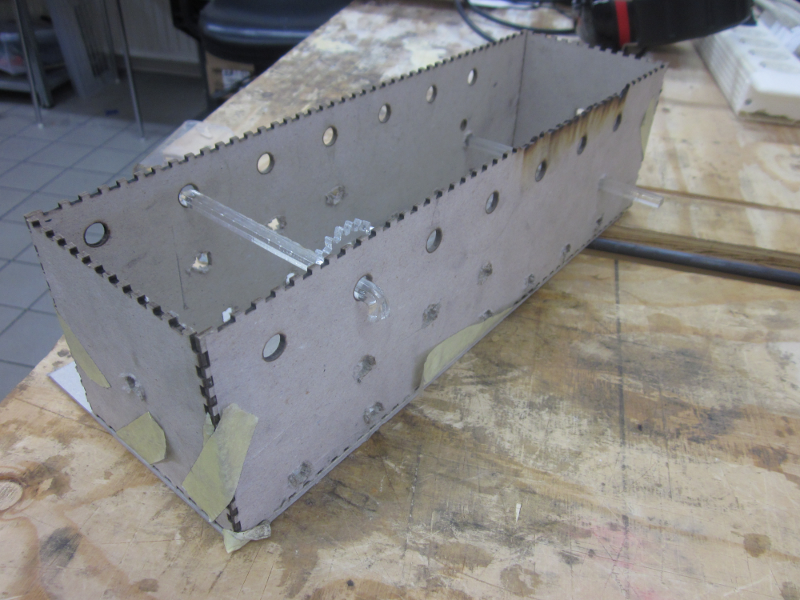

I've made all my tryouts first in carboard. which resulted in a box like this.

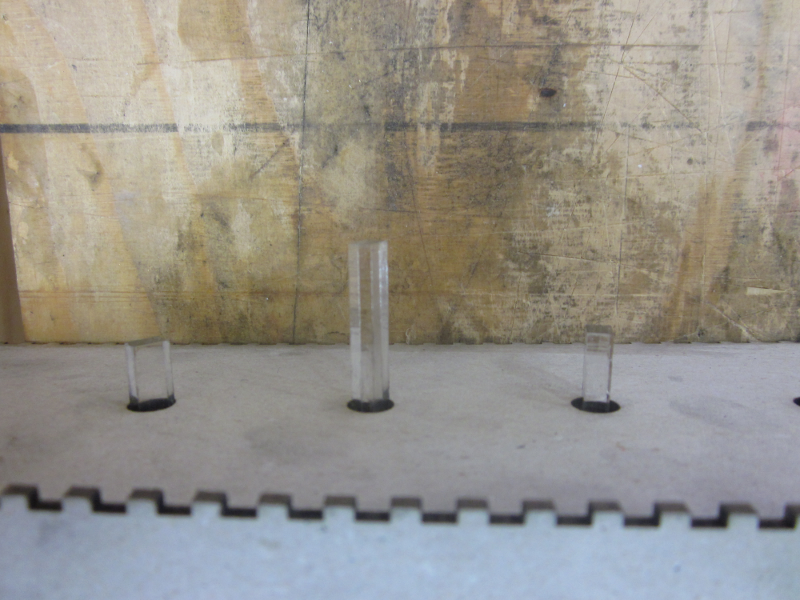

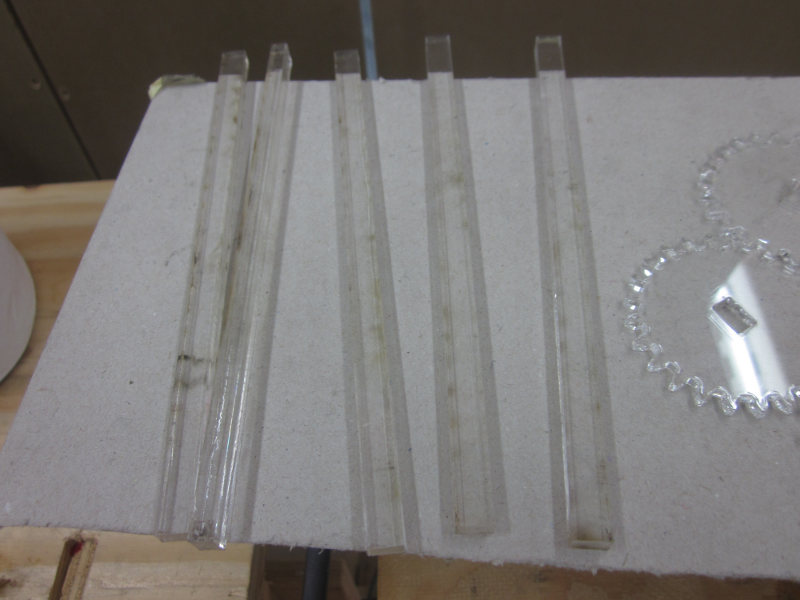

The settings that I used to cut it out were: (vector) speed: 40 / power: 100 / freq.: 5000 As you can see in the second picture I've done some tryouts in bending the plexiglas. This is to fasten the sticks with the gears on. I've tried an iron tube, headed up, as also the soldering device.

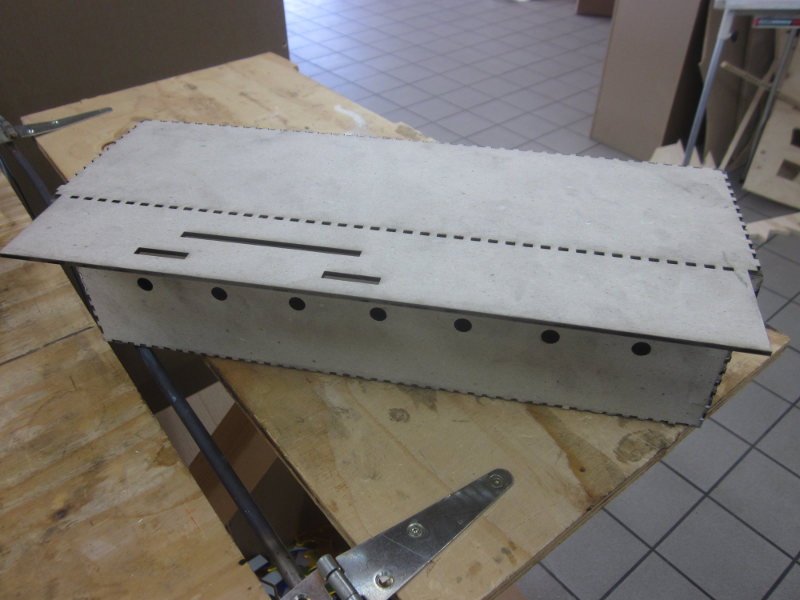

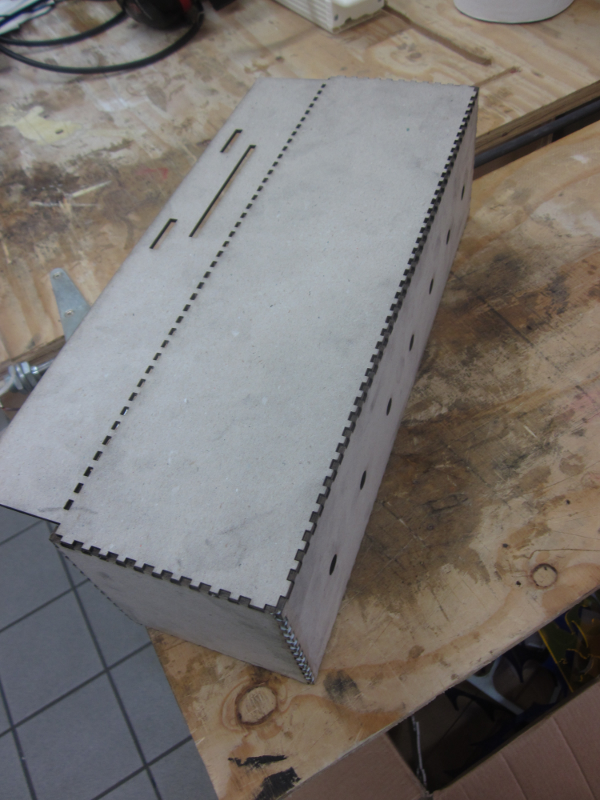

And the new box looks like this. I've made the top of the box bigger so that the automata itself will be visible.

About the holes. In previous tryouts I've always made the holes the same as the sticks. Wich resulted in not being able to turn.

Some of the inner gears:

The sticks that connect the gears with the automata:

And how much work do I have left? Lots of it. I still need to make the letters, finish making the automata, designing the electronics, making the circuit board, soldering it, programming it, changing the C/pyton file. And connect the motor to - of cource - the whole project. So, still lots of work to do.

And if you ask me what the most difficult part wil be, I'll answer you: designing the electronics in Eagle.