Project Sessions

WEEK 3 (6 February 2013)

[Computer-controlled Cutting]

In this class session me and my colleagues have designed a shelf model using wood and acrylic, after this first job we make a personal work and I designed a car mount holder.

(For this homework I used the Vinyl Cutter Machine and Laser Cutter machine.)

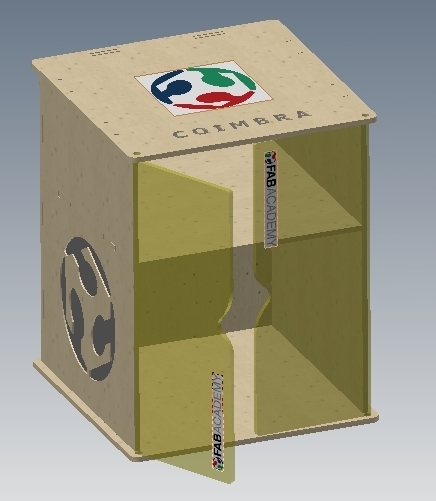

PRESS FIT CONSTRUCTION - First job was a press fit, I and my colleagues made a shelf model using wood and acrylic, we using the laser cutting machine and vinyl plotter to make the logo of the fab lab, we never used a laser cutting machine, so first we work together to understand the problems and then each of us will do its work individually. We also discussed about the best ways to do 2D, I personally use CAD and Archicad software.

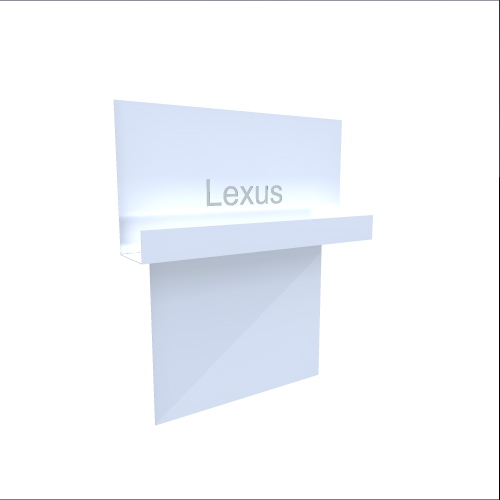

For my personal work I designed a car mount holder construction press fit for a Lexus 220D.

2. For modeling and Cading, I used the INVENTOR and ARCHICAD software. I used Parametric CAD tools to obtain the vectorial drawings needed for cutting the acrylic and for writting the logo.

3. Next step was to cut the acrylic using a laser cutter and also the assembly of the press fit.

4. The final result was the assembly process in the car, the object is quite simple but very functional for me.