Classes >>3D scanning and printing

|

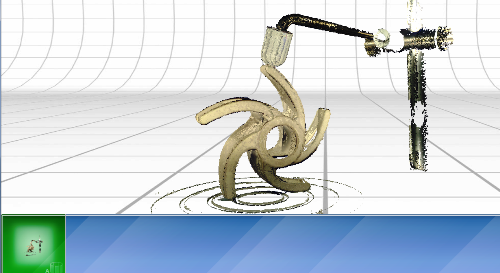

Here, using the NextEngine scan I am finding the best position for scanning |

|

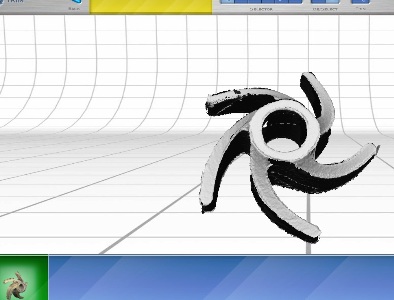

As you can see, for the laser reaches all the corners of the piece I wanted to locate it with the hole perpendicular to the laser beam because all the thicknesses were parallel but the results showed otherwise, not all corners of the element were achieved as the sufaces perpendicular to the laser beam |

|

After scanning we need to edit the impeller but by now it was imposible to correct and fill all the imperfection. Really I need to scan it on more than one position to solve this problem |

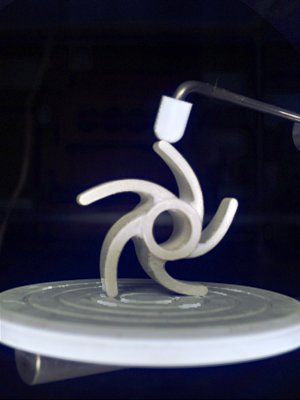

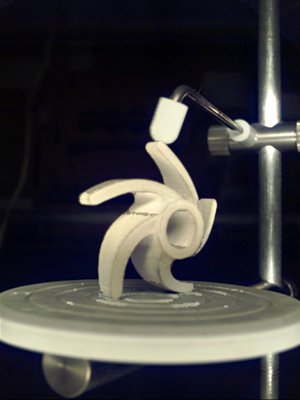

Well, to complete my task I am printing my impeller designed from Rhino usin he 3 UP 3D printer. The idea to choosing this element was to manufacture it with a material different from metal as the ABC material (used in the task) or PVC or another high strength polymer materials.

I was pleasantly surprised at what they were perfectly smooth surfaces of the blades as you can see in the pictures which makes it unnecessary to use later for the finish machining.