The build page for my final project, an afordable, desktop CNC Machine will be documented below.

The Design

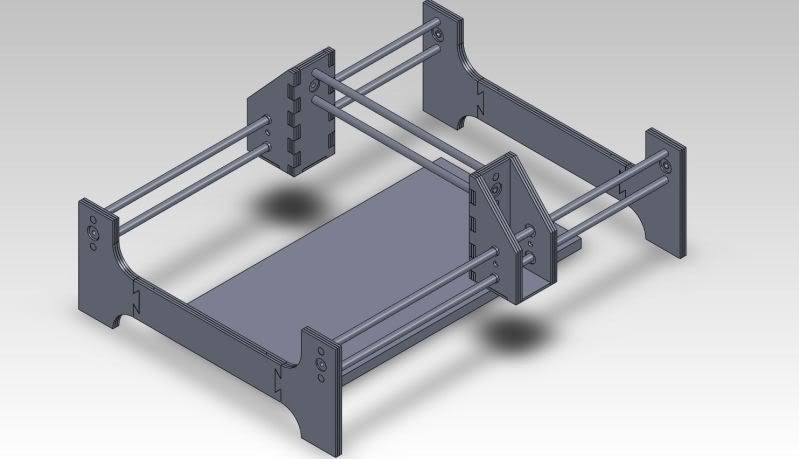

After looking at many of the designs that are available for commercial and personal use I decided to try to create a design that was able to be low cost and easy to build from scratch. Curretly, I am on my second version of the CNC machine's design. The first version can be seen below using smooth steel rods and being driven by threaded rods in the XYZ directions.

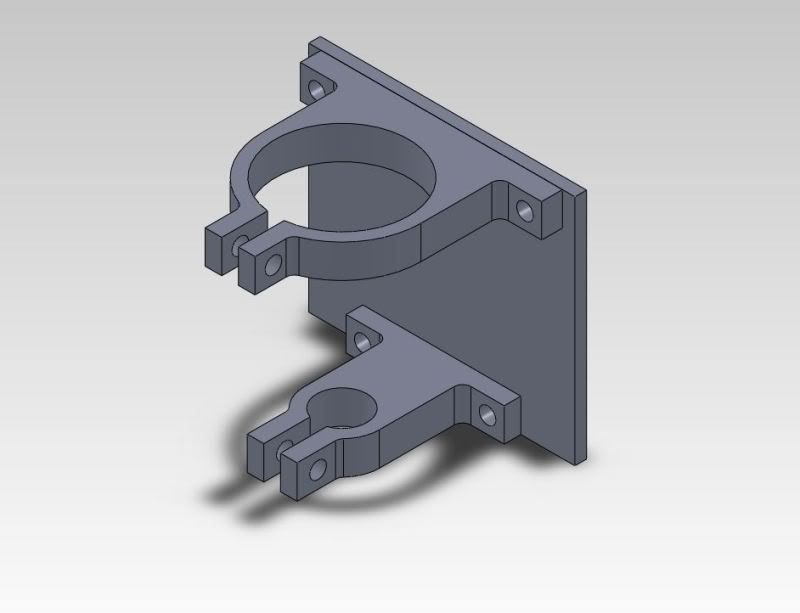

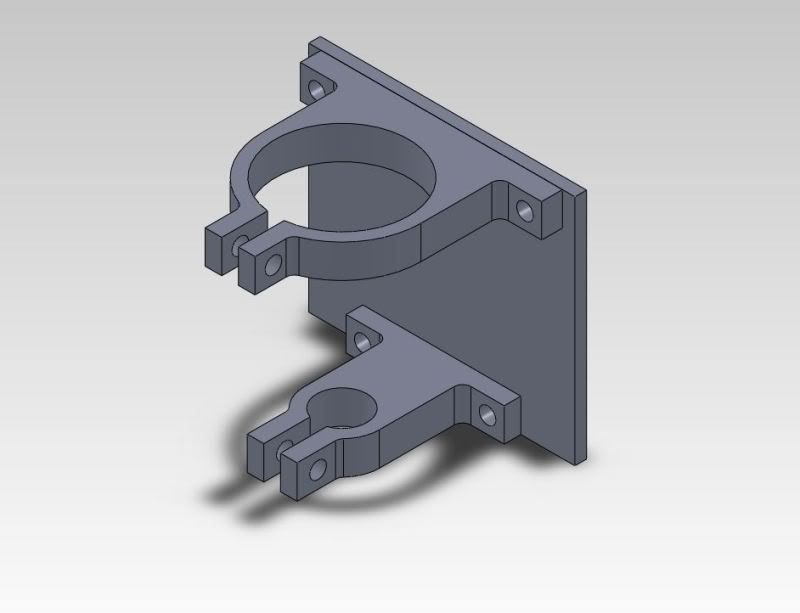

The cutting tool that would be used is a Dremel 300. While not the top of the line model it is a solid tool that is able to handle high speed cutting. A picture of the mounting brackets that I designed are pictured below.

After talking with Sean Wallace at an event at AS220 about a design he took part in in which he helped to create a small milling mahcine, I was able to get some great feedback on the design picuted above. Wallace was able to help me see that the current design might have issue which could cause it to bind up as it traveled along the Y axis (the 2'-0" length). As a result of that, I came up with a new design that should help to eliminate parts and cost while creating a stronger frame for the machine to operate within.

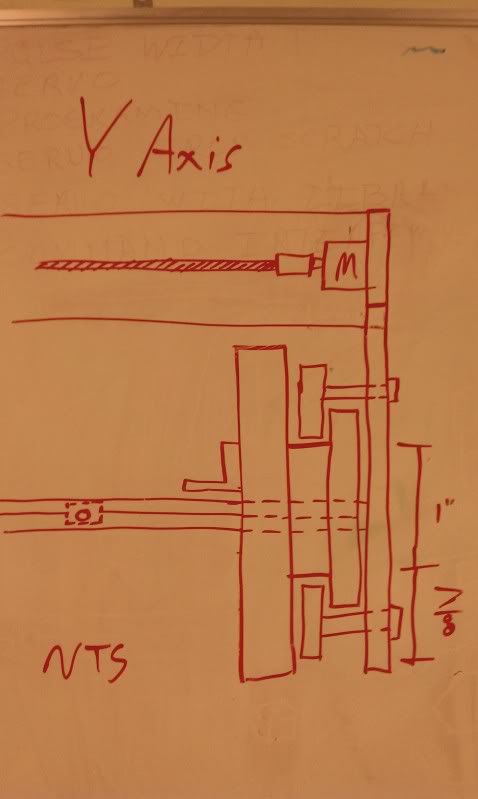

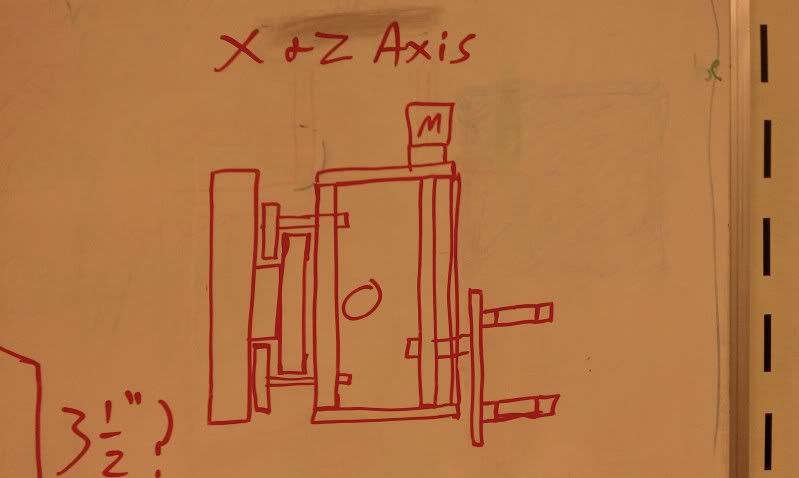

Below is a set of drawings that the newest version of the machine will be based upon. By eliminating the guide system that used smooth rods and oilite bearings, I will be able to replace it with a bearing track based system as see in the drawings below.

The picture here shows the Y axis that would travel along the 2'-0" portion of the machine. The threaded rod runs underneith of the buid platform pushing the two sides in a parallel motion using a captive nut system.

Note: Drawings Not To Scale

The picture below shows the setup for the X and Z axis. The X axis will work in much the same way that the Y axis. The drive rod for the X axis will be another captured nut that is housed within the same box as the Z axis drive rod and guide rods.

Here is a model that shows the mock up of the 2 clips that will be used to hold the Dremel tool. They will be milled out of 1/2" HDPE plastic. The reason for using HDPE over Alumium is because I have no way of milling alumium and HDPE is much cheaper. I could make these brackets out of MDF, however, while MDF is a great material to use for building things, it is not as good when it comes to being used as a clip. This is because there is no grain structure to help the material support itself under certain stresses and it is also much weaker than HDPE when milled to the shapes in the picture below.

More updates to come.