Classes > Molding, casting, and composites

I've been printing a part in the makerbot a lot of times. It's a support for making yagi antennas (I'm a radio amateur), so for the assigment of this week I thougt it'll be great to make a mould for it, so I can make these parts faster and cheaper, and also try some other materials than ABS plastic.

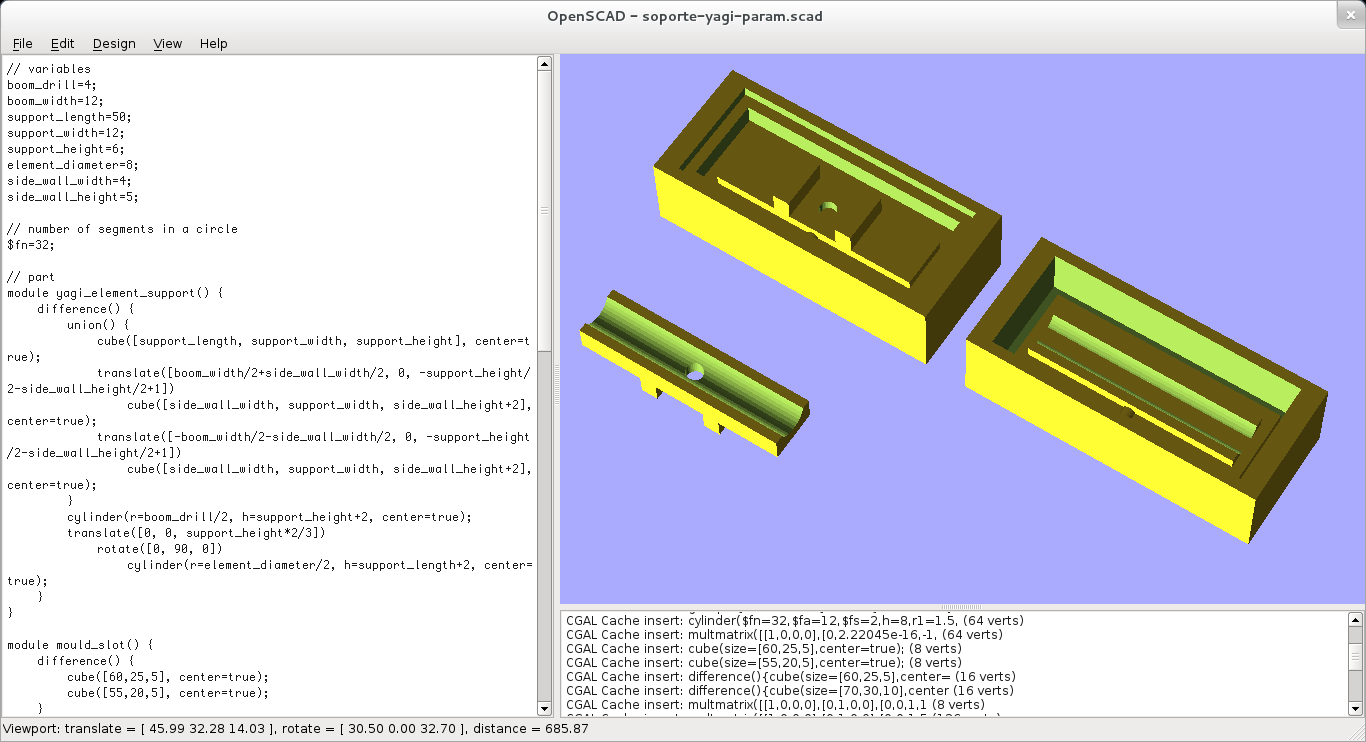

So I started designing the moulds for the casting. I decided to go with the positive mould/silicon negative mould/positive part method. As I designed the part in OpenSCAD, making the mould was not hard, using the part as a module, and using some boolean operations with prisms, this work was done.

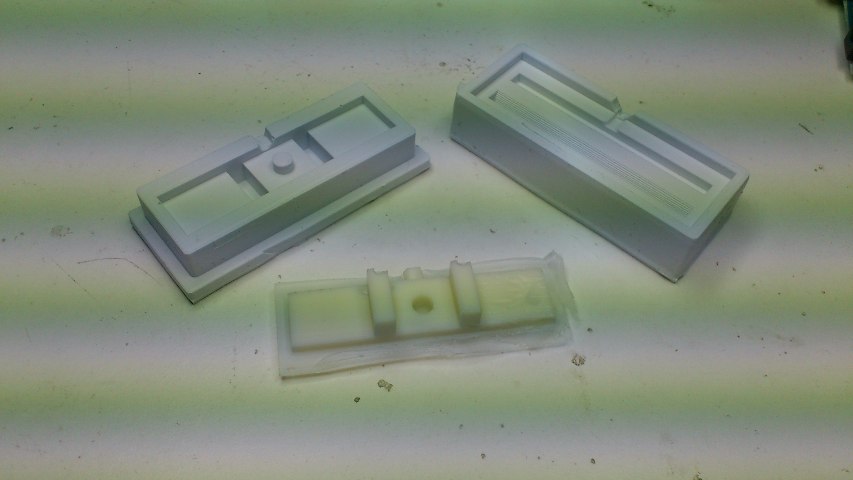

Then I exported the STLs and went to the modela to machine them. I used polyurethane foam I had at the lab to test the moulds, and after milling them they looked really nice.

Here you can see the test pre-moulds.

After this, I machined the wax pre-moulds..

and used silicon to make the final moulds.

![]()

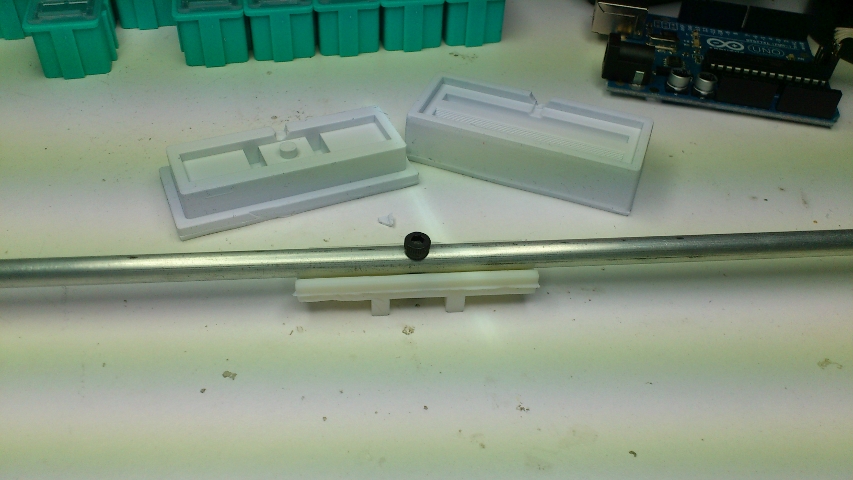

Then I used polyurethane to cast the part.

I got some bubbles in the process, but the part is nice and hard.

Here you can see the part working as intented, supporting an aluminium element for a yagi antenna. The legs are designed to mantain the part perpendicular to the antena boom, and are parametric (all the design is).

OpenSCAD file: