Classes > Electronics Production

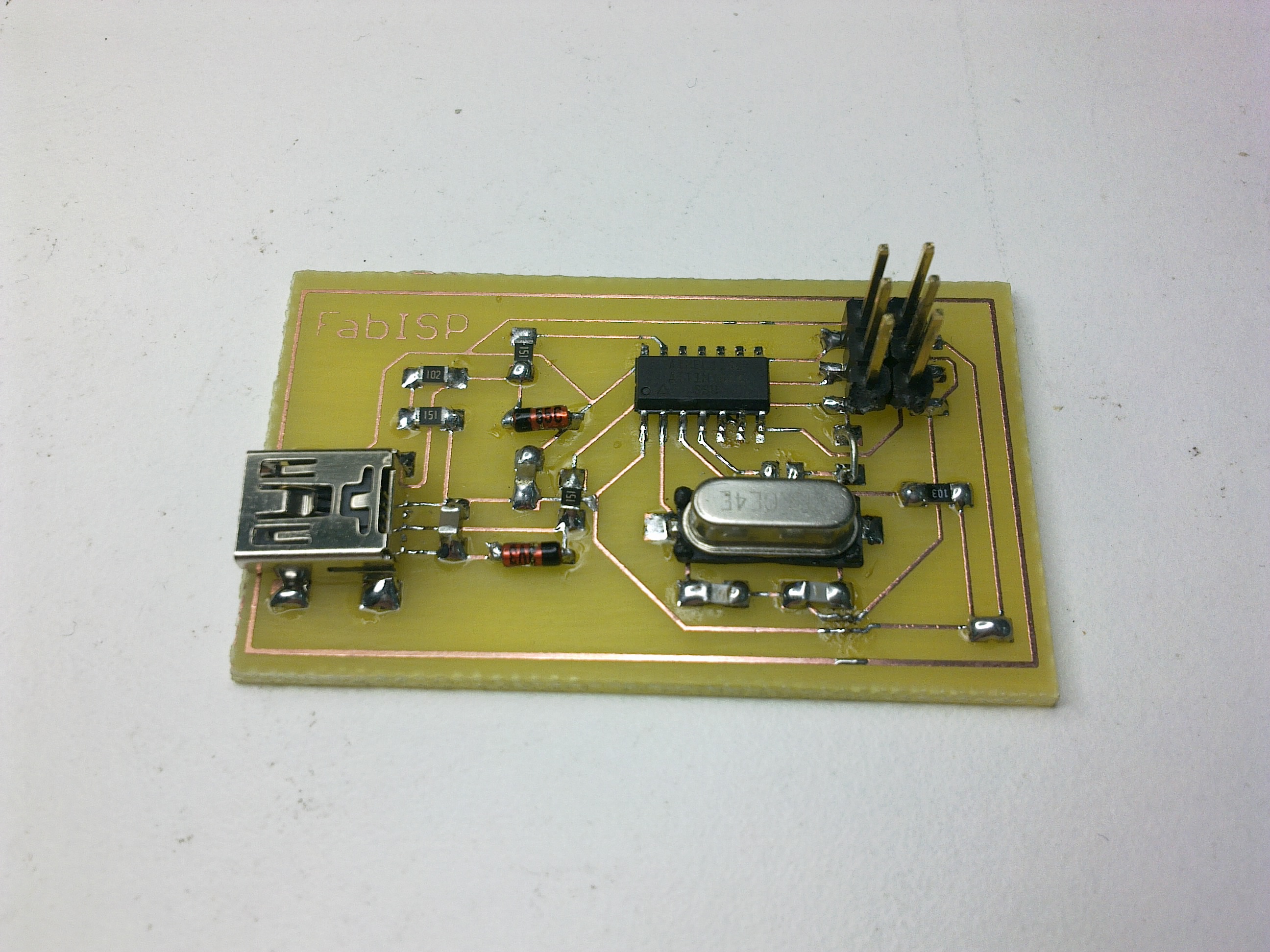

For this class, the assignment was to build, program and test the FabISP, an AVR in-system programmer based on the opensource USBTiny.

As we had no CNC bits smaller than 1mm left, we decided to make them using the traditional methond of UV curing and chemical etching. I have long experience with this process, as I've been doing electronics as a hobby since I was 10 or 11. We have a lot of PCBs with photosensitive layer at the lab, and we also have a professional UV box, PCB shear and so on, so it was fast and easy. We printed the mirrored design on trace paper (translucent), peeled the protection from the PCB and put them on the UV box for 130 seconds. This time was based on previous PCBs I did at the lab. Then we developed the PCB with a mix of caustic soda and water, and etched it with a 50%-50% mix of hydrochloric acid and hydrogen peroxide. The result was near perfect.

Then we started soldering, and realized that we had no 3.3V zenner diodes on SMD packages, just through-hole ones. So we cutted their legs and soldered them like SMD ones. It worked. We also ran out of 0 ohm SMD resistors so we used a bit of wire from the diode's legs as a bridge. Then tested for shorts, and programmed it with our AVRISP MkII. All perfect.

In order to test it, we programmed a small hello world (led blink) for an AVR Attiny2313 and programmed it using our new FabISP. It worked the first try.