Molding and Casting

This assignment was made in 3 parts:

--Design

--Milling

--Create Mold

Design

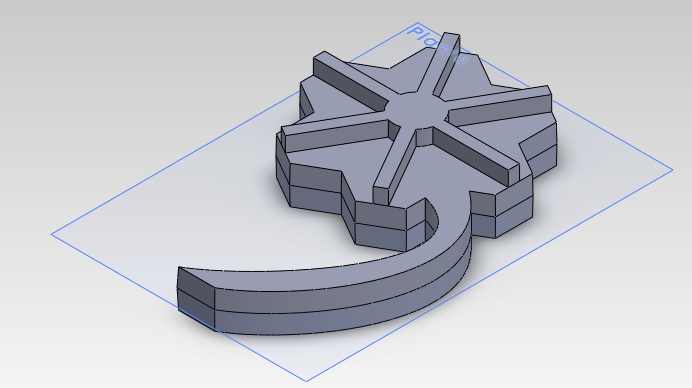

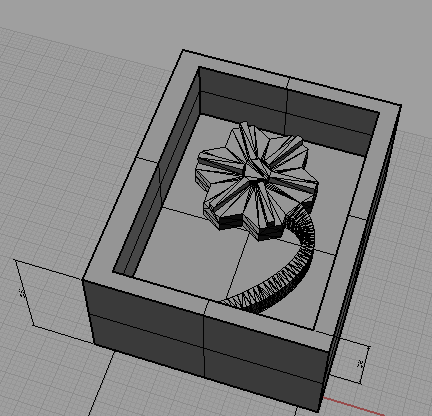

For the design I experimented with two software: Solidworks and Rhinoceros. At the beginning I wanted to make a mold of a leaf, but the forms possessing tough, I was not possible in Solidworks, well my design experience to I reduced it to make a flower-shaped ornament. I did the positive SolidWork, export the STL file, Rhino then used to design all around the flower, the results I got were as follows:

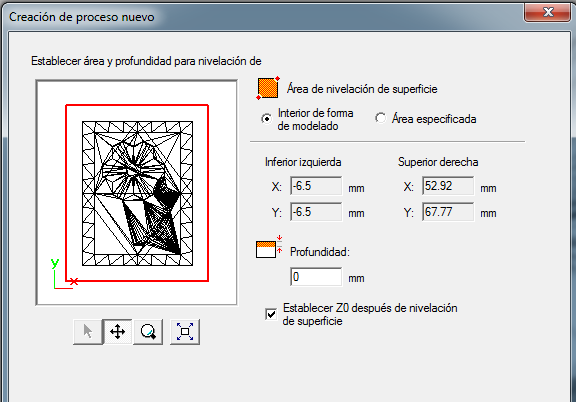

The edge of the box should be to 3.5mm of the extremes in X and Y, ethis distance is to make room for the mill of 3mm to be used. The thickness of the box is 5 mm, Z-axis height is 3mm more than the maximum height of your design

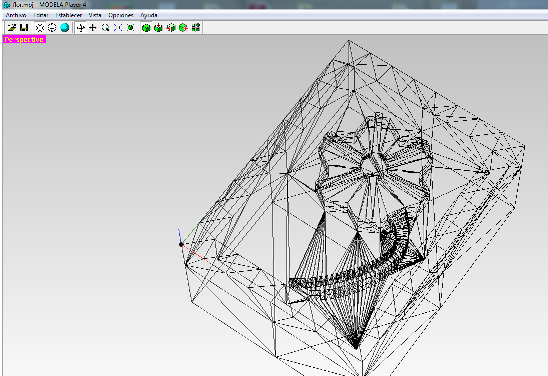

Milling

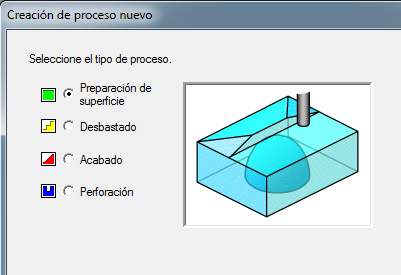

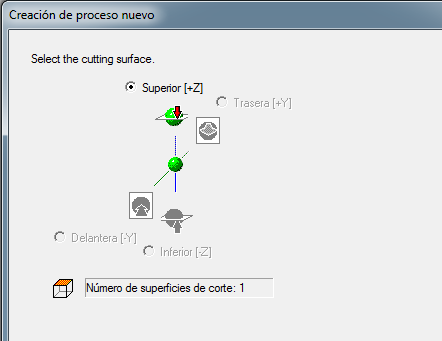

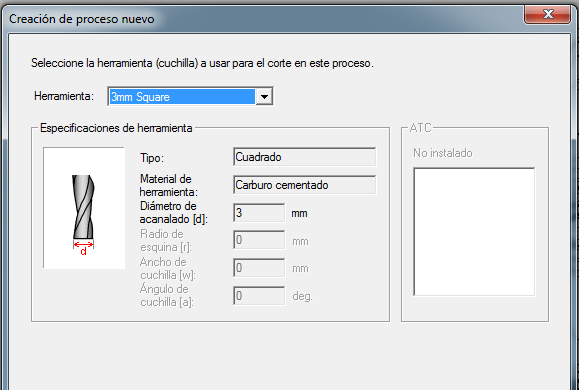

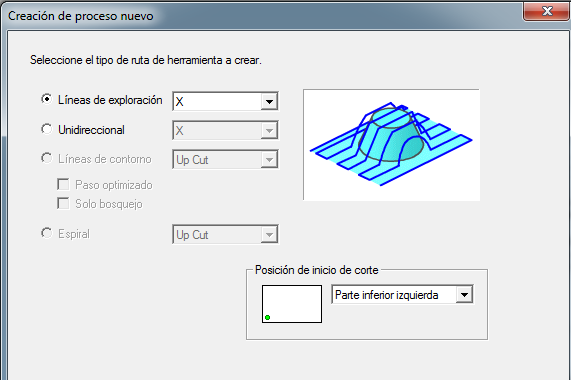

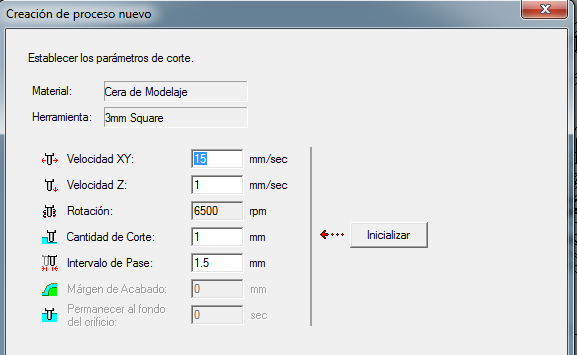

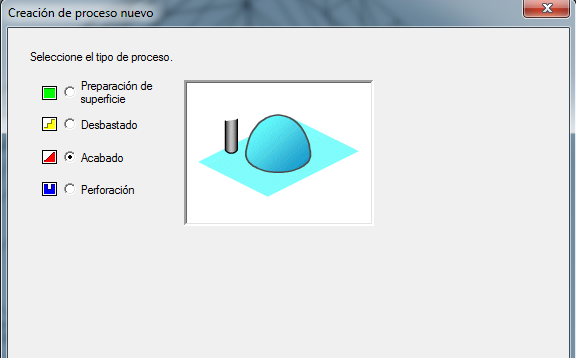

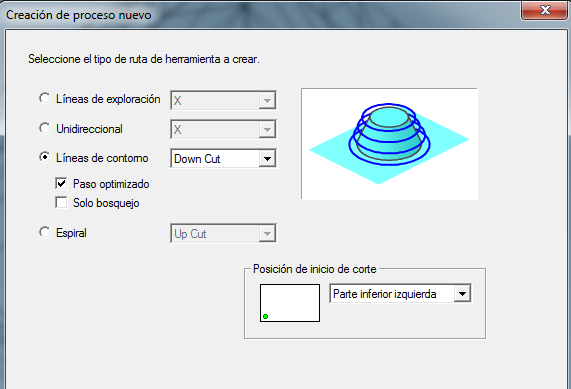

We use a 3mm diameter mill. The process is divided into two parts: Surface Preparation and finishing, these processes take some time because of the depth of your mold, in my case it took 20min I know other colleagues took more. Describe the process in pictures:

The process of finishing is equal except for the following:

The process of finishing is equal except for the following:

It is important to correct axes, because the drill may get out of the material, if we make the error, a way to fix it, is to focus manually wax, without moving the coordinates are in the software. The results of this process is as follows:

Create Mold

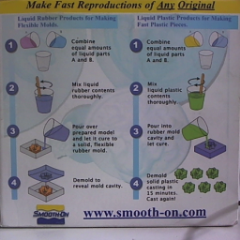

Using the following compound:

![]()

How to use it can be seen in the picture below, except that time was 4 hours

Is obtained as a result the following

Finally is used "gypsum cement" mixing with water in the proportion of 22gr of gypsum and 100gr of water, poured into the mold and results in