This is the Fab Academy class page of Anu Määttä. I’m part of the Amsterdam class, but actually reside in Helsinki, Finland, where Aalto Fablab is currently under construction.

This is the Fab Academy class page of Anu Määttä. I’m part of the Amsterdam class, but actually reside in Helsinki, Finland, where Aalto Fablab is currently under construction.

I used work at Fablab Utrecht (ProtoSpace) so am not all new to world of fabbing. But by the looks of things, there are plenty of things to learn still (and that’s very welcome). I’m really looking forward to learning more about what can be done & made at Fablabs and hoping to make lessons learned part of our lab as we go along developing it.

I studied computer science, with side twist of bioinformatics and genetics, and have mostly worked with software before stumbling across Fablabs. Looking forward to getting physical with code!

Weekly assignments list:

- 1: Plan and sketch possible semester project

- Final project: further considerations

- 2: Build a personal site

- 3: Render and animate a potential final project

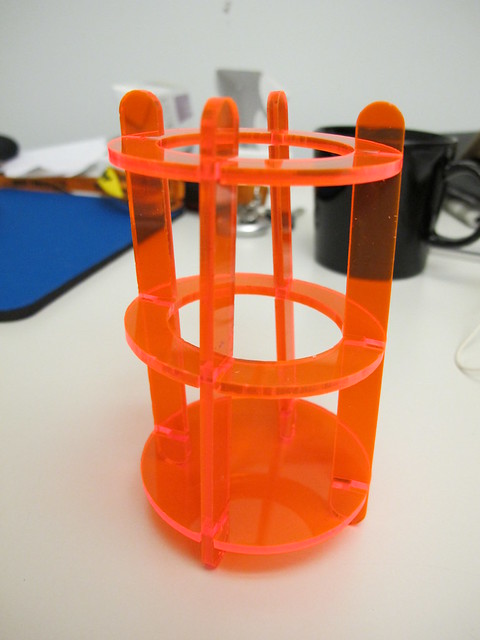

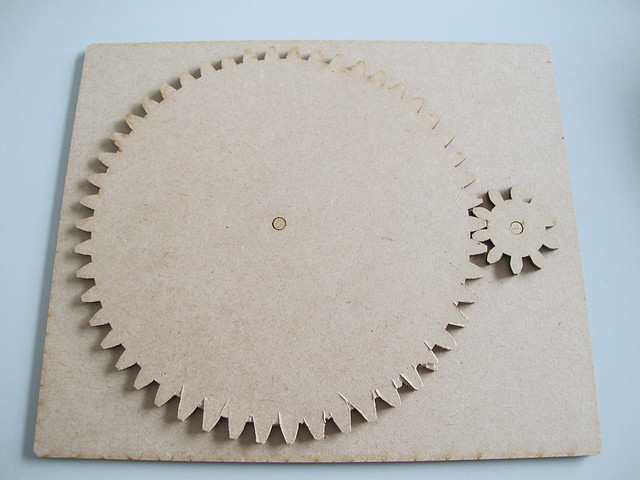

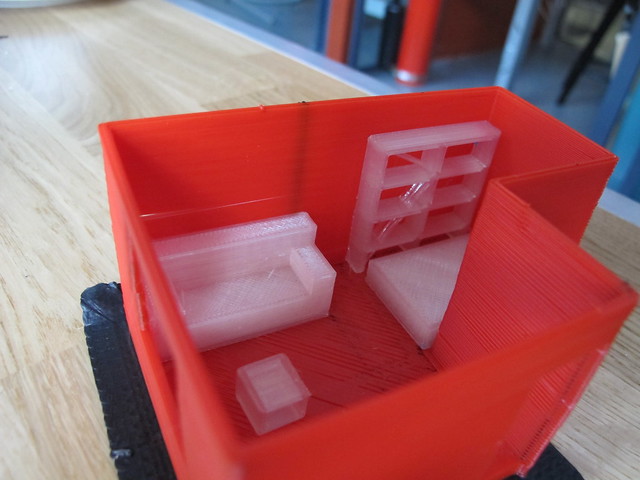

- 4: Press fit construction kit

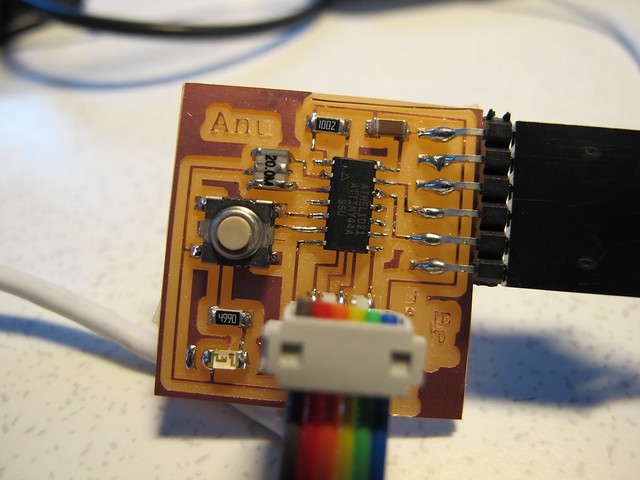

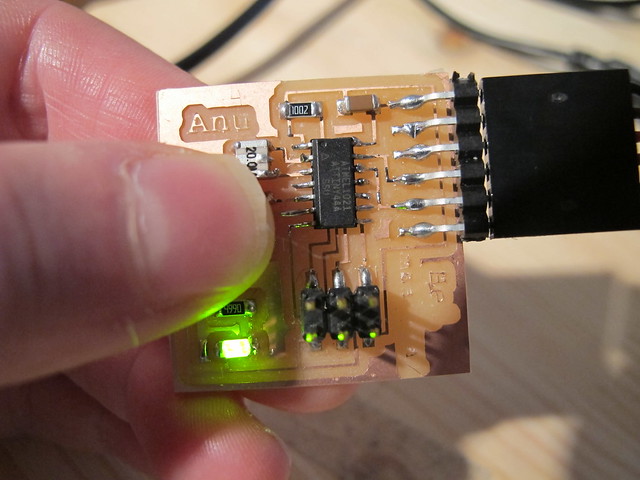

- 5: Electronics production

- 6: Make something big (Amsterdam)

- 7: Electronics design (Amsterdam)

- 8: Molding and casting

- 9: Embedded programming

- 11: Input Devices (Amsterdam)

- 12: Interface and application programming

- 13: Output devices (Amsterdam)

- 14: Final Project Update

- 14: Mechanical design

- 10: 3D scanning and printing

- 15: Networking and communications

- 16: Machine design

- 17: Planning the final project (Amsterdam)

- Final Project presentation