1. Finalized bookshelf design on Inkscape.

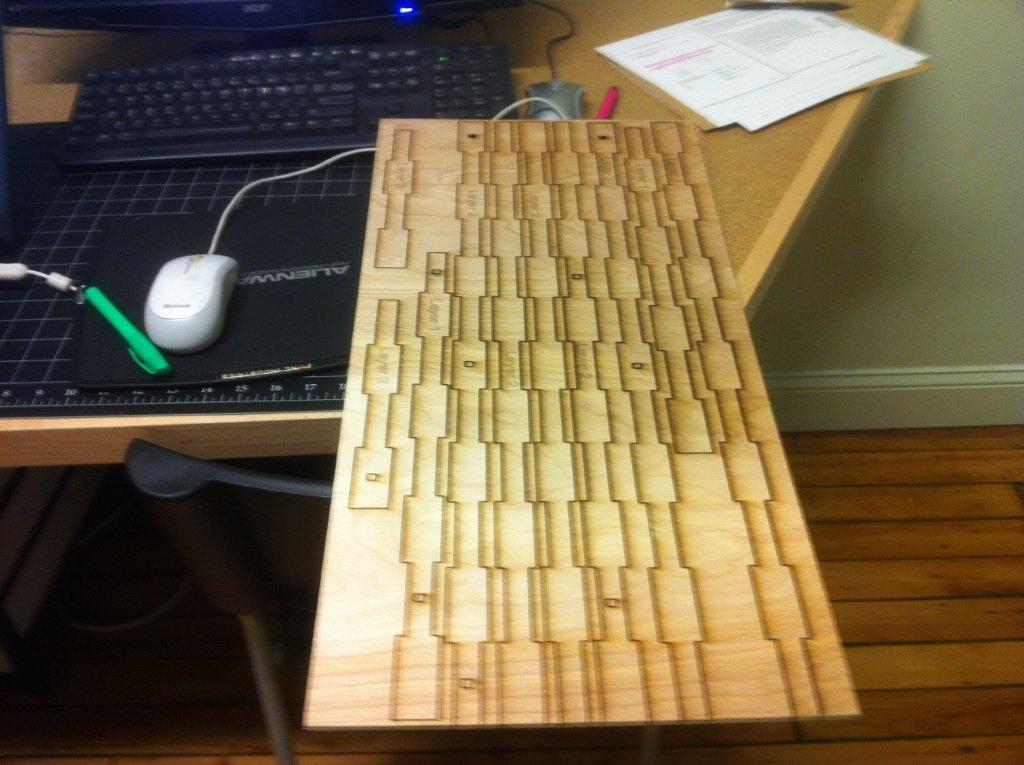

2. Attempted to laser cut 2-D elements.

3. Epilog laser cutter, whether due to warped bed, warped plywood, old laser tube, sunspots or phase of moon, is not cutting all the way through on most elements.

4. Tried various settings (speeds of

3%-8%, pulse of 450-3000 Hz, max power,) multiple cuts and

deliberate raising of the bed above focus, but the problem

persisted. James Rutter installed a new bed towards the end of the

process, which made the cut come through to at least the point

where I could trace it on the back side of the plywood with a box

cutter. Sanding off a layer off the back side helped, but was

difficult to do precisely without messing up the press fit.

5. Made three shelves and four vertical

support elements. The resulting shelf is fairly hinky.

6. Lessons learned:

a) Use a more appropriate cutting tool (CNC router or more powerful laser,) as the Epilog is not well suited to this kind of task (cutting eats up a lot of time, and cleaning up the cuts with a box cutter or belt sander takes more.)

b) 1/4" plywood shelves do not work well as support elements. Use both horizontal and diagonal support braces to tie the vertical elements together securely, and usethe former to support the shelves.

c) I really need to learn SolidWorks.