Fab Academy 2012

About Me

My Project

Classes

Computer Controlled Machining

Make something big

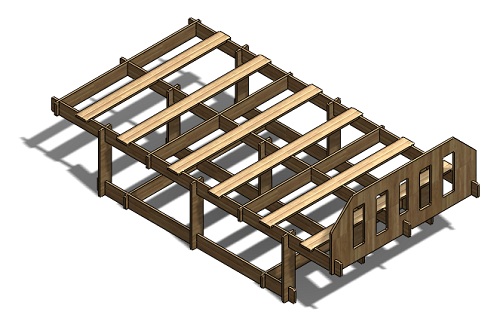

For this assignment I decided that I wanted to make something functional and I chose to make a single bed. One of my concerns was whether the 12mm (1/2") plywood would be strong enough to support a person laid on it.

Actually it was not the laying on it that was a concern, it was lateral movement that concerned me more. I designed the bed to be as supported as possible but I was restricted to keeping my design to one sheet of plywood which measured 2440x1220x12 (8x4x1/2").

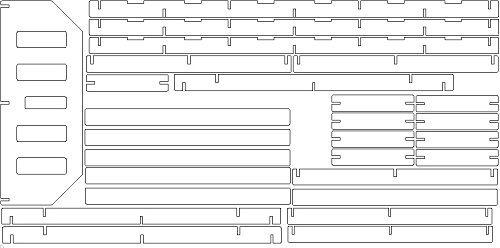

I sketched my design on paper first and then drew it up in Inkscape. I made the page size match the size of the plywood and drew up each part, I then exported the .dxf files to SolidWorks and modelled the bed to check that it would all go together. After a few adjustments I was happy that my bed could be made from one sheet of ply, my layout to be machined is shown below.

Machining

To machine the bed from the plywood board I used the Shopbot router.

I found this to be an excellent machine to use and having used CNC machines in the past I found its operation to be very intuitive and was comfortable with the software.

The only real problem I encountered was that the router left some rough edges on the plywood where it had torn rather than cut. I must take the blame for this as it was user error. Having never used a router of this size before I underestimated how much the workpeice can flex on a job of this scale and I did not secure the plywood in enough places. This left me with more work to do to clean up my parts afterwards, lesson learned.

Another mistake I made was in laying out my parts in Inkscape, I made one too many of one part and one too few of another. I have fixed this in my drawing now which was easy but I did not have enough leftover material to make the missing part.

Thanks to the community spirit of Fab Labs and the kindness of one of my fellow Fab Academy students I was able to fit the design of my missing part on some spare space of another job.

Thank you David Collins

Assembly

As mentioned previously I had some work to do in cleaning up my parts after machining.

Fortunately, after cleaning the parts they fit together perfectly and the bed was as I had envisioned it.