Fab Academy 2012

About Me

My Project

Classes

Electronics Production

PCB Fabrication

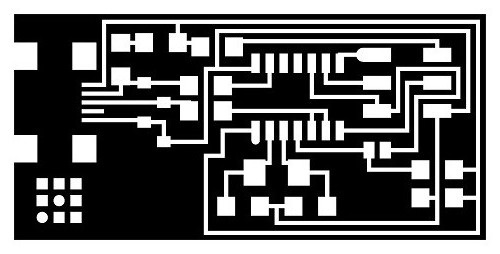

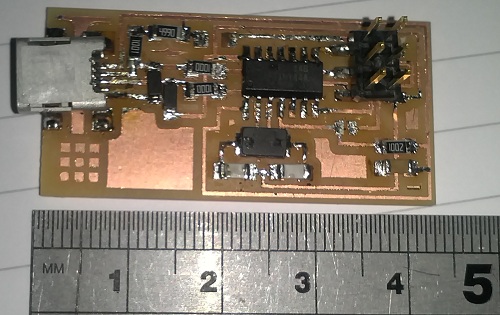

FabISP The PCB for the FabISP was manufactured on the Roland Modela. The tracks were cut using a 1/64" end mill, and the outline was cut using a 1/32" end mill; both plans were created using the Fab Modules

The material the board was cut from was FR1, this is copper clad phenolic paper.

Components The components used to propogate the board were all surface mount

Using these components was an interesting experience and here are some tips I would like to share:

1. You need very good eyesight (or some form of magnification)

2. You need very steady hands

3. It really would be handy to have 3 hands

4. Get the ATtiny44 chip orientated correctly (desoldering 8 legged chips is not fun)

5. Getting it wrong again and again is character building

Firmware

I installed the firmware using another FabISP that had already been created and it installed straight away without any difficulties

The workflow for installing the firmware was as follows:

1. Download and unpack the firmware

2. Edit the makefile

-Check device is ATtiny44

-Check speed is 20MHz

-Check the correct avrdude is selected

3. Send the firmware to the ATtiny44 using the following commands from the same folder as the makefile:

-sudo make clean

-sudo make hex

-sudo make fuse

With the firmware installed I then removed the 2 solder joints so that my board would work as an ISP

The final step was to make the IDC ISP cable, this was simple; I used a 6 wire ribbon cable and push down IDC connectors

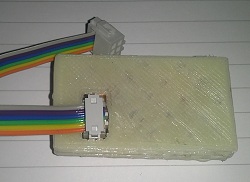

Case

I wanted to make a case to protect my FabISP and so I drew one up in Solid Works and used my RepRap Mendel to print the case

The polymer I am currently using for my RepRap is Green PLA that glows in the dark