Fab Academy 2012

About Me

My Project

Classes

Computer Controlled Cutting

Laser Cutter

The Epilog laser cutter that we have in the Fab Lab is capable of vector cutting and engraving and raster engraving. It is a very easy to use machine but must not be left unattended as it cuts using a burning process.

Kerf is the size of the cut made by the laser, in the case of the Epilog the kerf size is 0.2mm

When making push fit parts on the laser allowances should be made for the thickness of the kerf. Push fit models rely on an interference fit and a 45 degree chamfer should be put on all male tabs to make act as a guide for the pressing movement.

Push fit kit

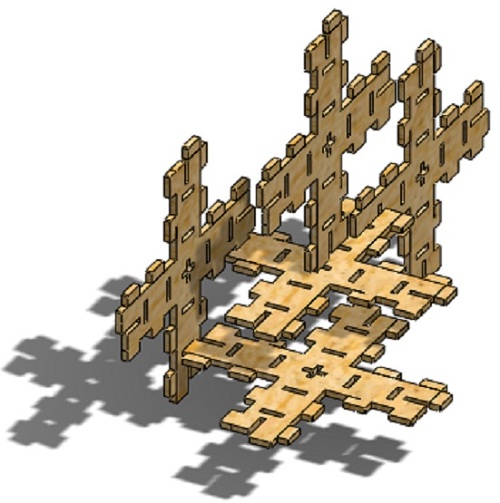

I have created a push fit kit that consists of many parts of just one design that can be assembled in many different configurations.

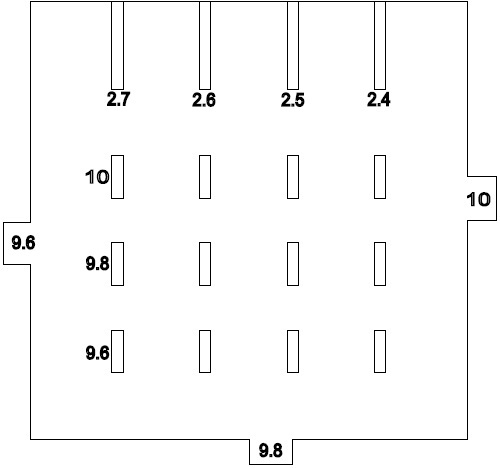

I used card which I measured as being 2.7mm in diameter. I created a test piece first using a range of different sized tabs, hole, and slots so that I could find the optimum sizes to use in my model.

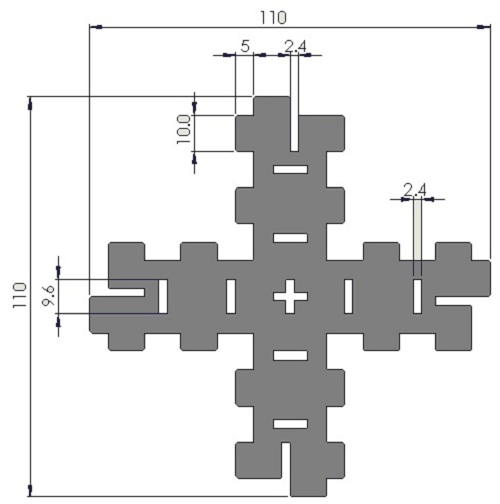

From this test I found that for my application I should use tabs that are 10mm wide, slots that are 2.4mm wide, and holes that are 2.4mm x 9.6mm

I then drew up a design for a part that could be mated with other parts of the same design in many different configurations and cut these on the Epilog laser cutter.

I drew this part as a sketch in Solidworks and saved it as a .dxf , I then transferred it to Inkscape and saved the design as a .pdf which I sent to the laser to be cut out.

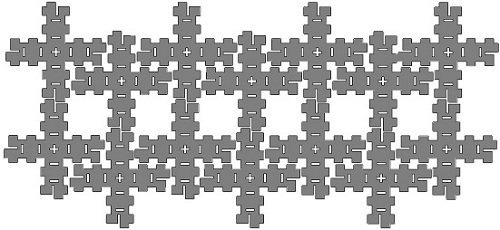

After I had cut 2 of my parts and tested that they fit together as intended I then used the whole of the lasers bed to cut a full sheet of parts.

I now had 16 parts in total and I was able to begin fitting them together as the SolidWorks Assembly below shows.