molding and casting.

composites

emmotllament

i colada. compostos

assignment

design a 3D mold, machine it, and cast parts from it.

molding

and casting

I have done a one part mold for casting chocolate. The mold has a wood

"insert", a thin stick that permits to do a lollypop.

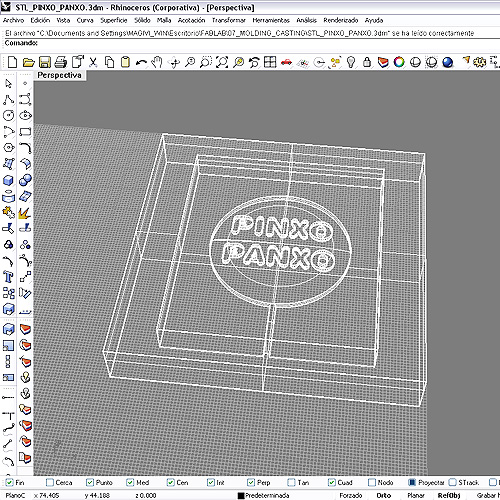

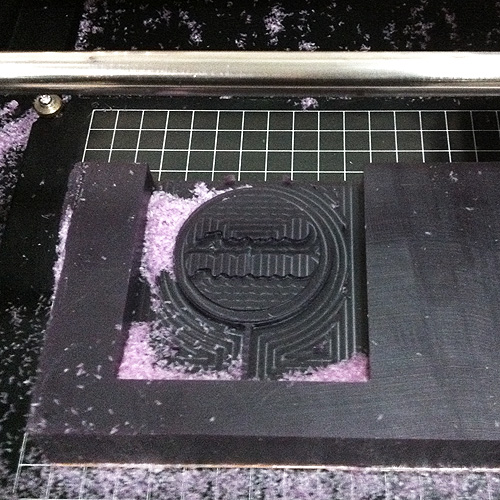

The model has been done with Rhino 4.0 and exported as a STL file to mill

it. I used the fabmodules, first with a 1/8 rough drill and after with

a 1/32 finish mill because the definition of the letters. I had to reset

the default parameters of the tool. I changed the diameter to 0.79 mm.

(the 1/32 inches equivalence in mm.).

I had problems with the width of the mold, one of the walls stayed open

and I had to close with a piece of methacrylate.

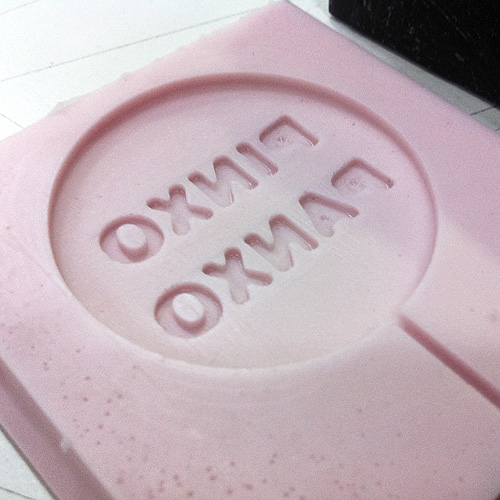

After casting the liquid silicone (mixing the two components) has waited

a minimum of 24 hours. It has been demolded the silicone mold for casting

liquid chocolate and it has waited until cooled down to take the lollipop.

This is the result.

01.the chocolate lollypop

02. the molding proces

re-using

wax

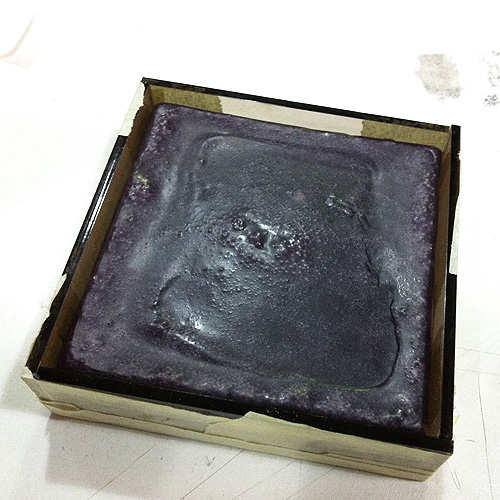

We have proven to reuse the wax shavings from the milling. After heating

the wax, we put the liquid wax inside a methacrylate mold and allowed

to cool.

03.reusing the wax

produced milling the molds

folding

mold

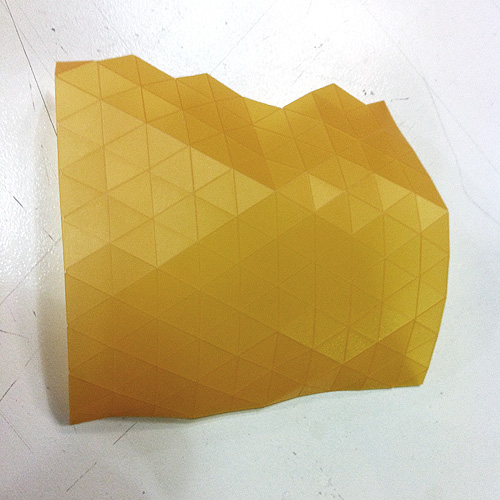

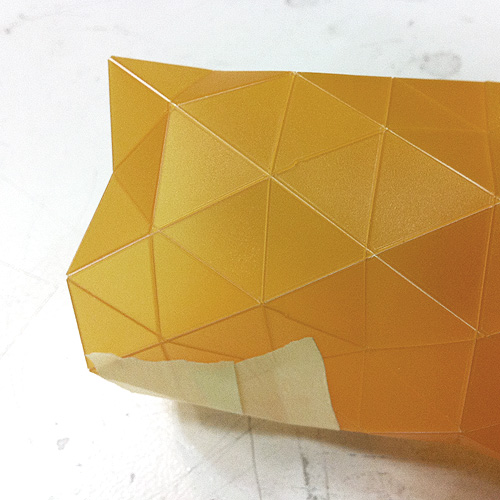

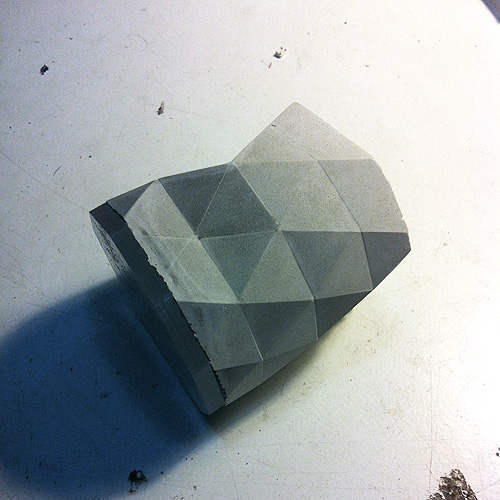

I tried o do another kind of molding using plastic board and graving

a geometric pattern in it. After wrapping it in the way we want you

can cast any piece and any material. I have no tried yet...

04.mold using a graved plastic

board