FabLab Academy 2012

Manchester Lab

David Forgham-Bailey

Comments:

Software:

Hardware: Roland Modela

Weekly Assignment:

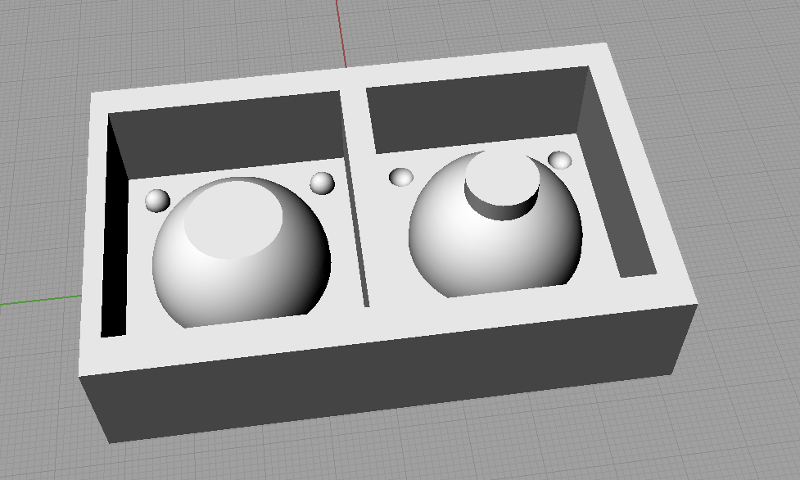

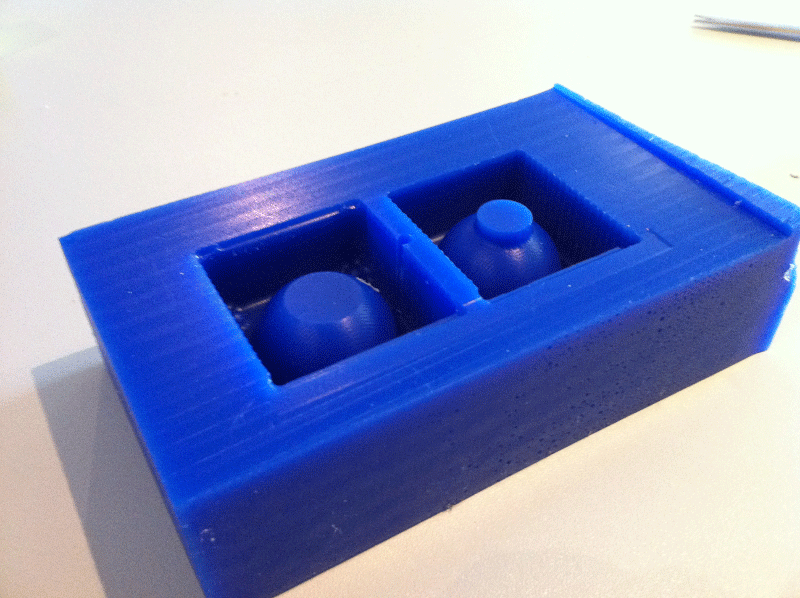

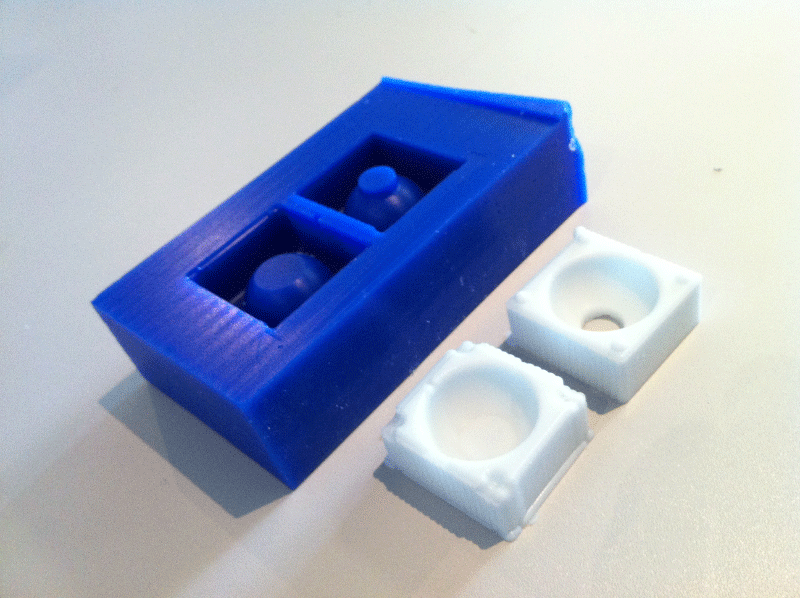

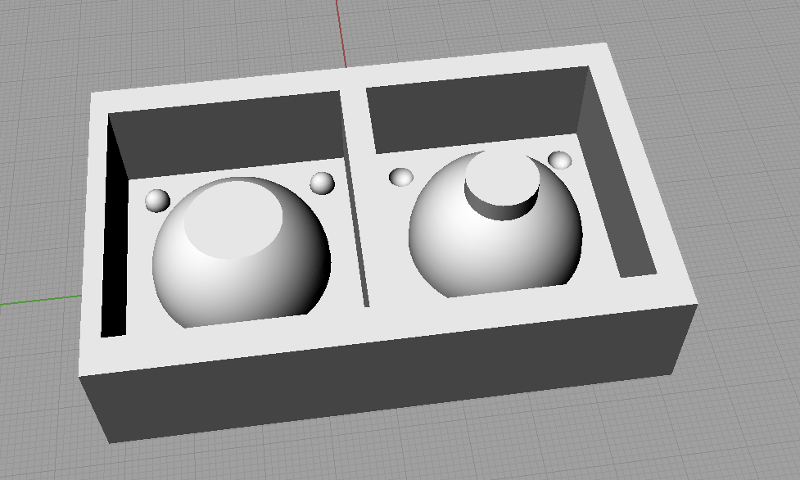

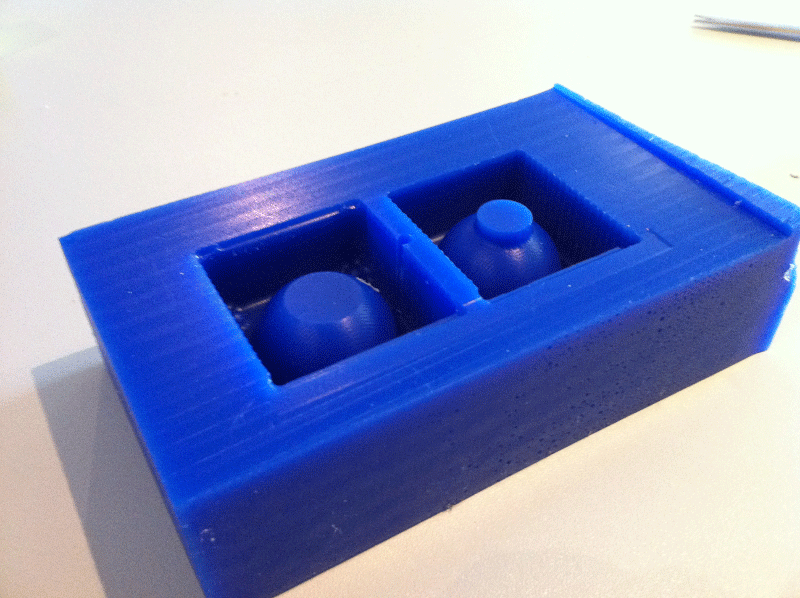

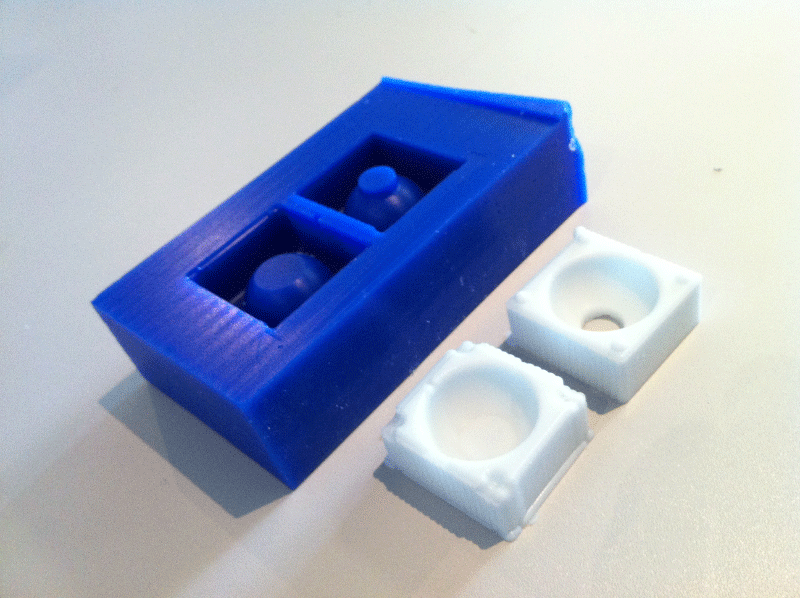

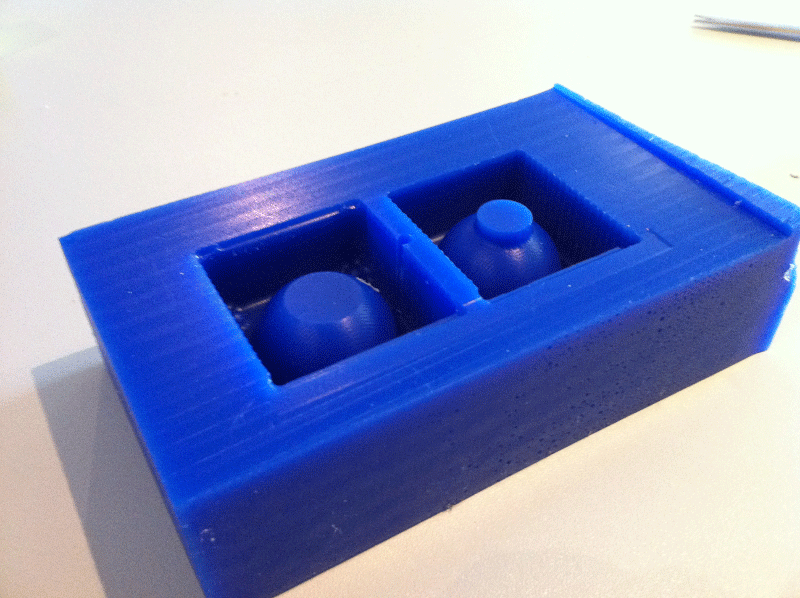

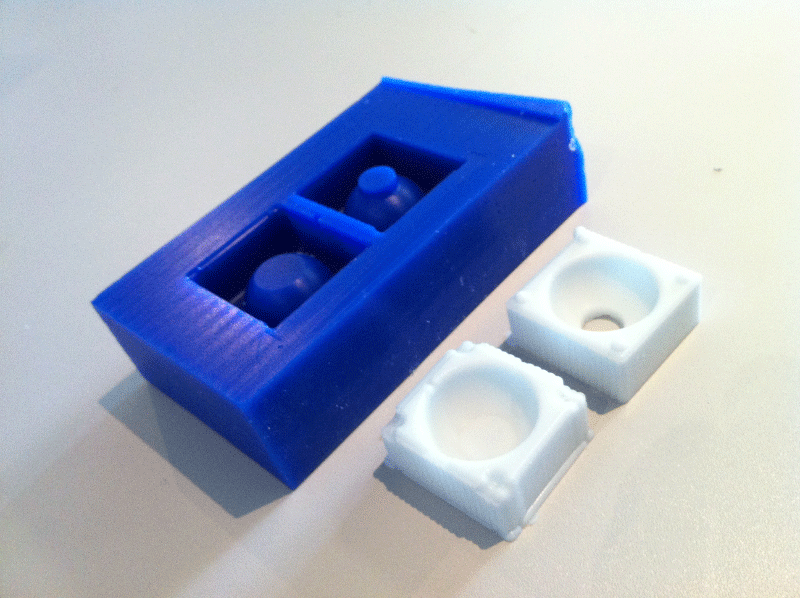

I decided to make an eyeball unit for my final project. We were

restricted to milling a wax block, then using this to form a silicone

mould, from which the final 3D shape will be cast.

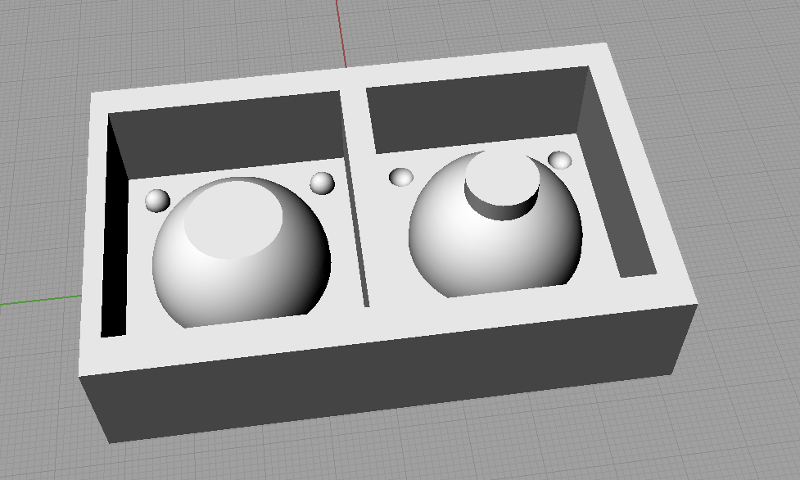

I designed a two part mould which will produce a silicone mould

(2 part - with registration lugs and pouring/filling spout -

Narrative:

having

produced

the .stl file the milling path is made my Modela

Player. The wax block is first cut to make the top face flat and tool

zeroed. Next path is the roughing out - leave enough work for a final

cut with a round nose tool. Finishing cut is final path - this will

determine the quality of the finished item.

.

Materials:

Machine Settings:

Photos:

<>

Files:

Drawings:

External Links:

Course Notes:

Similar to 3D printing but better finish and quicker - Good for short

production run - not good for parts within parts -

Injection - sprue/runner/gate/vent/partition line/flashing

insert casting - place object in mould before casting

vacuum - blow - inflate - bottles - flexible - start with rigid

material then use flexible - need mould release - make part and bend

mould to demould

machinable wax - high temp wax - remelt and reuse - melt shavings from

machining - remelt and reuse - Good Surface finish

low temp wax - good for transferring - make mould from other objects

rigid foam - building material - use on ShopBot - glue sheets together

for deeper mould - not good finish due to granular foam use Gesso to

seal then sand.

alginate gel - non toxic - one shot use - good for body casts

urethane rubber - plastic - stick to each other - v stretchy -

silicone - not as stretchy - completely inert - will not stick

PDMS - Latex - avoid - cures by drying - takes many coats - take long

time

thermoplastic - fluid when heated - thermoset - needs heat to cure

Drystone - fancy plaster - adds polymer matrix to strengthen - quick dry

Hydro Stone - mix of portland cement and plaster takes a little longer

- cheap $30 - 50lb - waste is just rock - good starting point low

viscosity -

metal powder - ceramic powder - low temp alloys - glass can

be moulded - food -

additives - fibres - add strength - -fillers - add other

characteristics - glass spheres for bulk - other s for

conductivity/density/flexibility/colour/etc

Beware - if water is added to eurothane plastic it will foam -

mixing - mix well

deairing - removes bubles - avoid getting bubbles in first place -

vacuum chamber - residue

when stirring use shear - you have 10-15 mins to work and have bubbles

removed - filling pour slowly - tilt mould so vent on top design mould

for vent to work correctly

curing 150 degC - silicone use desk lamp to elevate temp - exothermic -

gets hot when curing

demould - taper - release agent - washing up liquid - shelf life 6-12

mths will not cur if too old - Keep container ring clean - will not

open if cures in place

safety - materil safety data sheet - disposable gloves - ventilation -

protection - can make you sensitive to the material

weekly project use - silicone rubber - hydrostone - drystone - 3D

toolpath - depth of cut must be possible with selected tool - what is

the cut depth of the tool?

Rough cut in layers to remove material - finish cut follows surface of

the part - tool overlap -

flat end mill for flat surfaces - ball end for round surfaces -

Composites - strong compression - not good in tension - composite makes

tension good - epoxy/carbon fibre - toxic - concrete/rebar - -adobe -

friendly composites - fabris with matrix - epoxy eurothane - needs

ventilation - oat building uses all materials - processes - compaction

infusion - 50/50 volume fraction

open mould - 1 side - *.png good at preserving dimensions