FabLab Academy 2012

Manchester Lab

David Forgham-Bailey

more than just cutting - upto 7 axis and more - robotic arm etc -

Roland Modela

Shopbot

KUMA

Type of material influences type of tool -

Materials:

Rigid foam insulation - polyeurothane foam - veneer plywood - mdf -

moulds/final parts - MDO - OSB-aluminium - Lexon-polycarbonate glass

Find local suppliers for materials....

TOOL BREAKAGE

Tooling: moves swarf away form cut - ONSRUD- SDS TOOLS - find uk

equiv... - Coatings: - make tool harder - A1TIN - cast iron - hard -

T1C - vioet brown - alloys - Titanium Nitrate - Gold - Gen purpose -

T1DR - specialist

centre cutting/slot cutting - up/down cut - good for finish on both

sides of ply - takes waste away from cut and face of material

mechanical feed - cutting depth - flat/bull end - flat cuts rectangular

slots - rough path leaves steps - bull finishing tool - use smaller

step order -

Diameter of tool / tool holding diam - steps shorter than flute depth -

length of tool - ensure long enough for work - Speed: - rpm of cutter -

feed - speed in lateral plane - Wood - highest rpm is 18000 see tooling

catalogue for speed/feed chart - 1/4 in tool (0.015mm) 18000rpm -

chipload calculator for Shopbot - if tool is hot after cut then feed

rate too slow

Lubricants: dishwasher fluid?

Fixturing: vises/clamps/screws - design positions when designing tool

path - draw hole where not cutting path - double sided carpet tape -

adhesive - encapsulation -

Kerf - diam of tool - offset - thickness of tool - cut on

inside/outside/on line - (changes with tool width)

Rhinocam-file formats -

Safety:

Comments:

Software: - Inkscape/Rhino/

Hardware: ShopBot - sanding equipment -

Weekly Assignment:

Make Something Big

Narrative:

I began this task with the firm idea of making a magic box - I have

had woodworking plans for manufacturing a magic box for a number of

years. But on reflection, the clash between Open Source and The

Magician's Code persuaded me to find something different.

I found an old plan of a 4x8ft sheet of ply which made a workstation

and matching stool and left no waste material - I spent a weekend

rejigging the plan to incorporate snapfit joints and made up a 3D model

to ensure the joints were correctly aligned. - I had reservations

about being able to secure the plywood to the Shopbot bed - but hoped

it might be

possible to use carpet tape. I decided to have a reserve plan if

this was not possible.

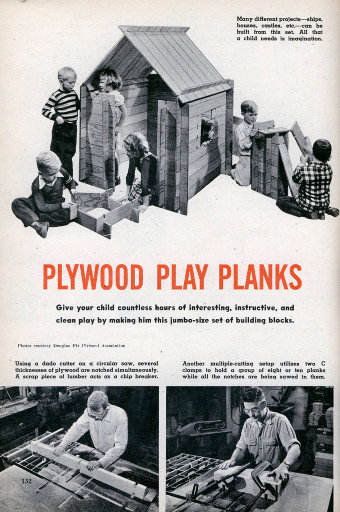

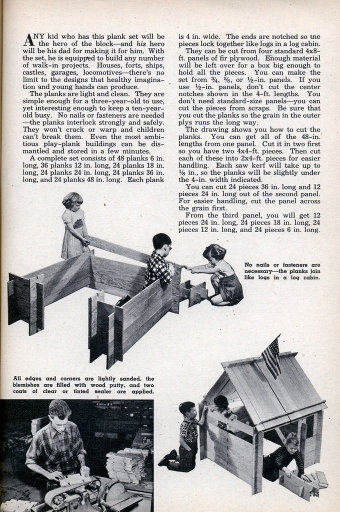

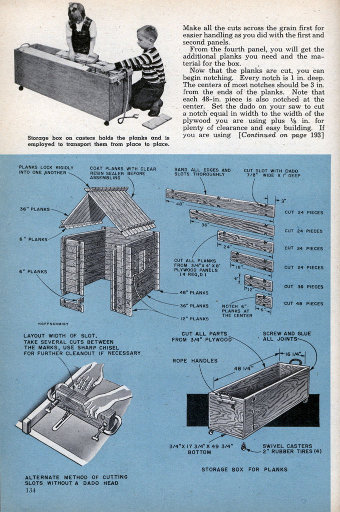

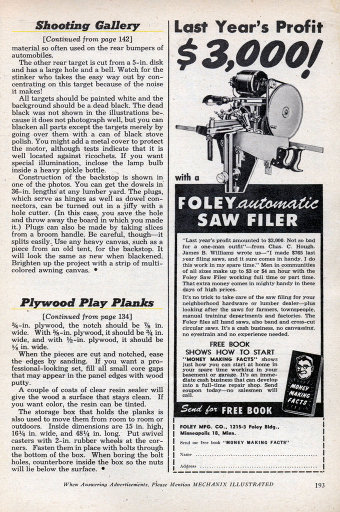

My research for ideas brought me to a set of play planks which I had as

a

child in the 1950's - (see images) - these are now called linkerlogs

and an opensource project.

From Mechanics Illustrated Dec 1953:

I used

Materials: 1/2inch plywood sheet - 4ft x 8ft

Machine Settings:1/4inch tool(up/down cut) - 18000rpm

Photos:

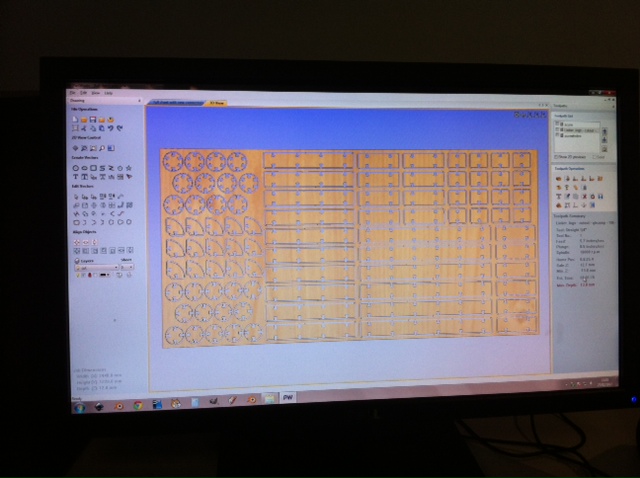

Toolpath:

Shopbot bed - in action:

Kit Assembled:

Files:

Drawings:

External Links: