FabLab Academy 2012

Manchester Lab

David Forgham-Bailey

Vinyl cutter:

Laser cutter:

Assignment: design, make, and document a press-fit construction kit.

My inital thoughts were to make a protoype for a kit which could make

mechanical models.

The kit would contain a frame into which the mechanism is mounted. A

variet of components such as Rods/ Cams/ Levers/Gears would fit

together axels and linkages.

For the prototype I designed a series of A4 sheets, using Inkscape,

which would include dovetail type joints to make up the frame and axels

and slots to connect the rods, cams etc to the axels.

Since we were to use cardboard, the kit has been constucted using

inches as the base unit with a grid set to 1/8 inch.

The frame would be a 6 inch box and the axels would be a square

cross-section.

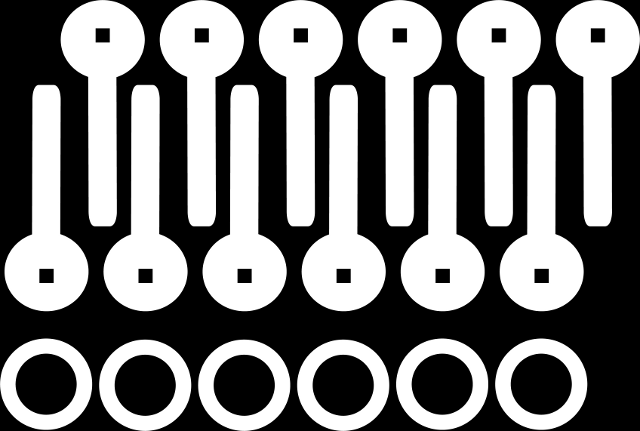

The prototype would be designed to be able to make up a caterpillar

whose body moves when a handle is turned.

Once this principle is proved then other components would be designed

to allow the kit to be able to contruct a number of type of machine.

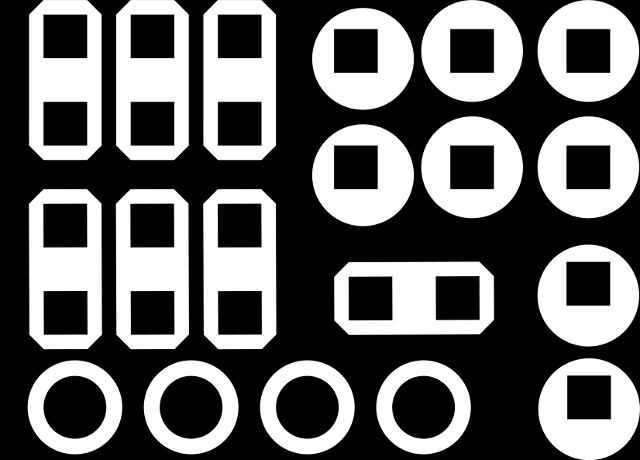

One joint was tested with the material to extablish the best tolerances

for the joints and slots.

Once the design is created in Inkscape as .svg - save as pdf with line

set to .1mm for vector cut.

For raster cut set lines to .5mm

Laser cutter settings in the driver control for printing pdf file

depend on the material to be cut.

Photos and drawings:

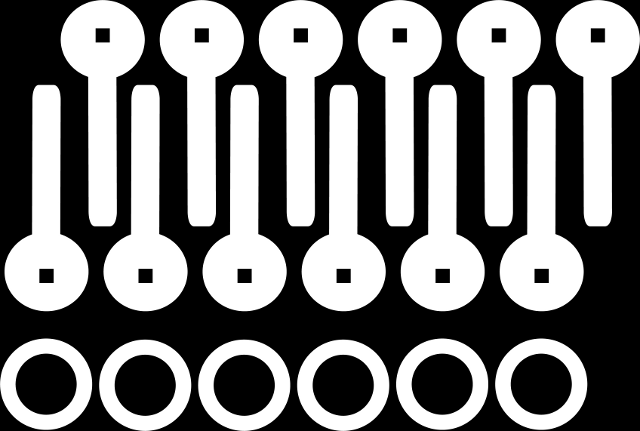

Caterpillar prototype assembled

Caterpillar prototype

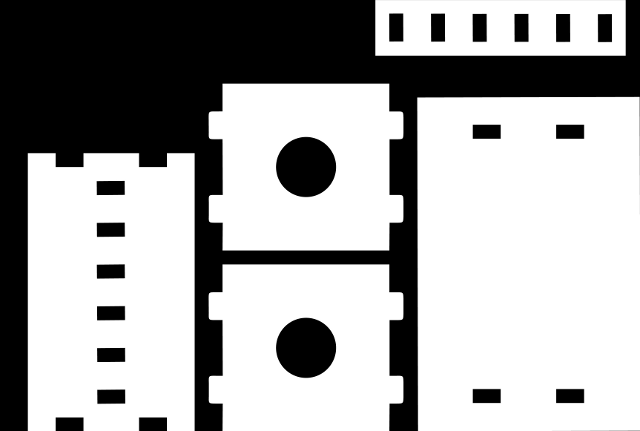

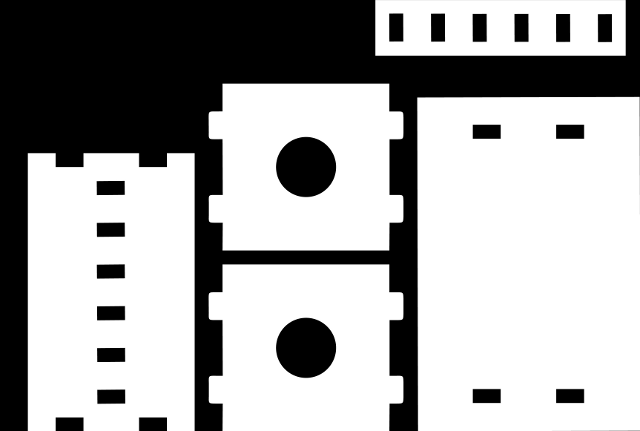

Laser Cutter with cardboard snapfit cutout

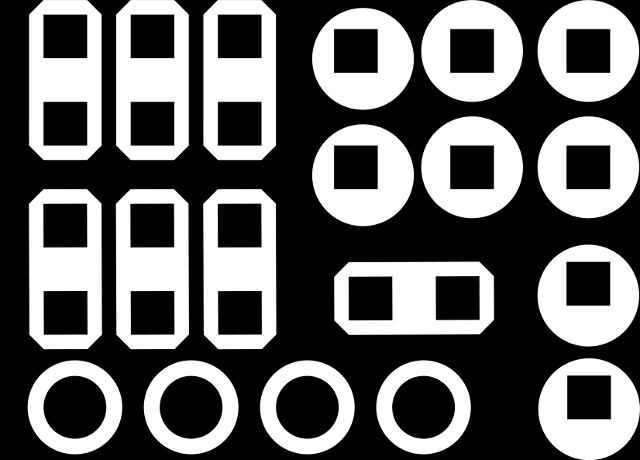

Here are the sheets:

Axels:

Cams/Rods

Caterpillar Body

Frame