FabLab Academy 2012

Manchester Lab

David Forgham-Bailey

The assignment this week was to

measure something - add a sensor to a microcontroller board and read it.

I decided to make all the example

boards to investigate the different sensors, and evaluate which whould

be appropriate for my final project.

When starting to mill the boards with the Modela the results were very

poor - part of the first board was not milled.

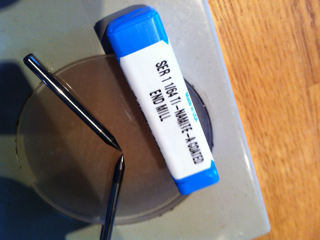

I decided to change the bit - I also ended up refitting the sacrificial

base plate.

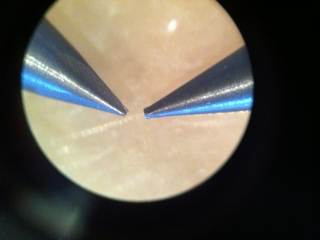

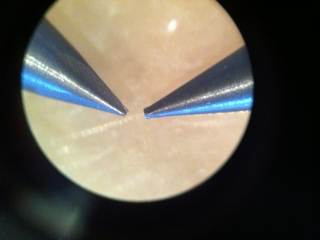

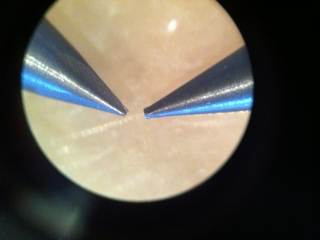

Below shows a comparison of the bits under a microscope -

1/64th End Mill bits - under microscope to show worn tool:

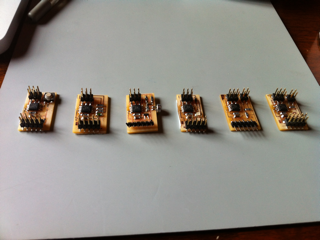

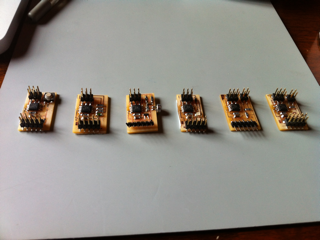

Completed boards: button/temp/mic/light/load/TxRx

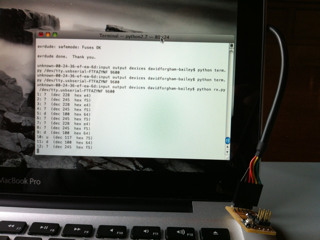

Each board was programmed by

compiling the c file using -

'sudo make -f hello.button.45

make' (substitute button with:

temp/mic/light/load/load/txrx)

and the board programmed by connecting the fabisp board -

'sudo make -f hello.button.45

make program-usbtiny' (substitute button with:

temp/mic/light/load/load/txrx)

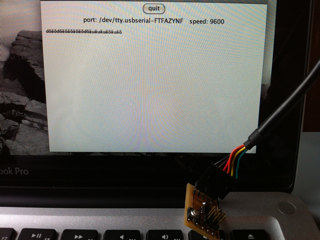

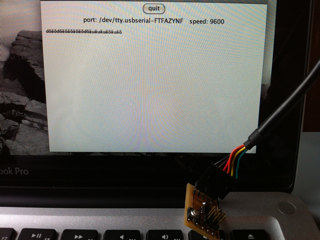

The Fabisp was then disconnected and the FTDI cable was used to connect

the board to my computer via the usb.

To find out the FTDI port address type: 'ls /dev' in terminal - FTFAZYNF

To read the output using Python Ptinker type:

'python term.py /dev/tty.usbserial-FTFAZYNF 9600' - or -

'python rx.py /dev/tty.usbserial-FTFAZYNF 9600' - in

terminal

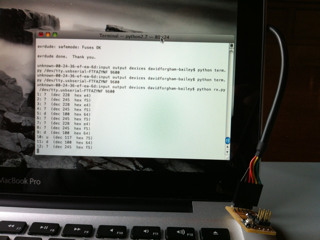

Button: term.py/ rx.py - should read 'd' when pressed/ 'u' when

not pressed: not always accurate with spurious characters being

output...

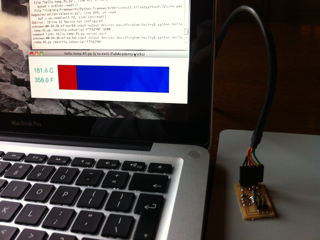

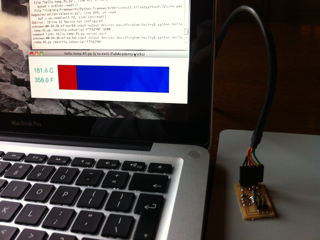

Temp: reading 181.6 at room temp/ 993.9 when touched with finger:

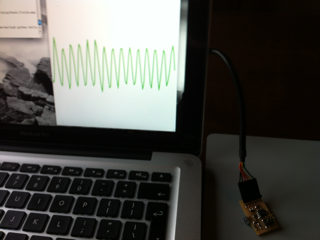

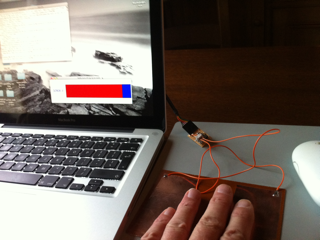

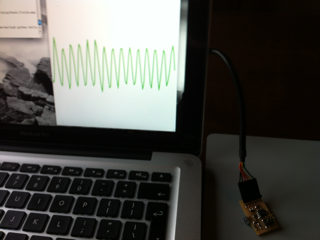

Mic: showing response to whistle (single tone):

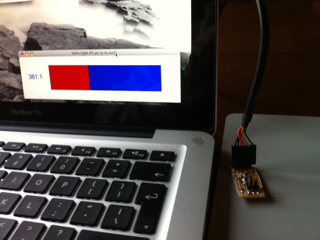

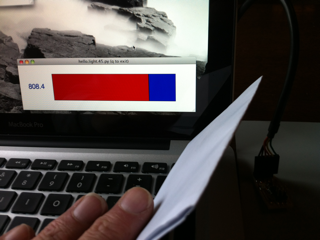

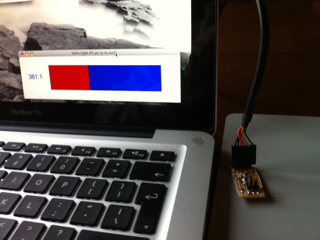

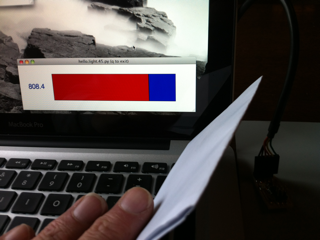

Light: showing response 381.1 to ambient light/ 808.4 to shade

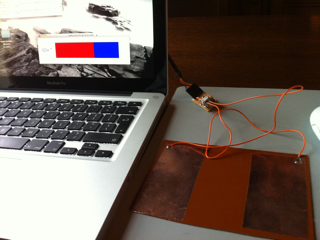

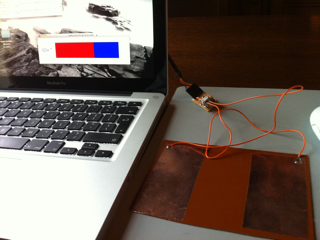

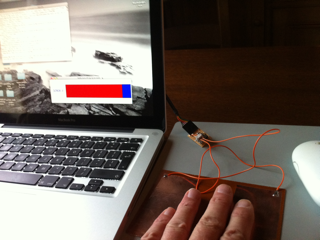

Step (TxRx): showing response 6234 open/ 32806 touched

although each board gave an output the value od the result was not

calibrated.