suspitition

suspitition Weekly Assignment:

* 3D scan an object

- extra credit: make the

scanner

* design and 3D print an object (small,

few cm)

- extra credit: edit

and print an object that you scanned

Narrative:

There are a number of ways to produce a 3D scan but first I

investigated using the iPhone/iPad. There are a number of apps which

claim to produce 3D scans by using the camera on the device.

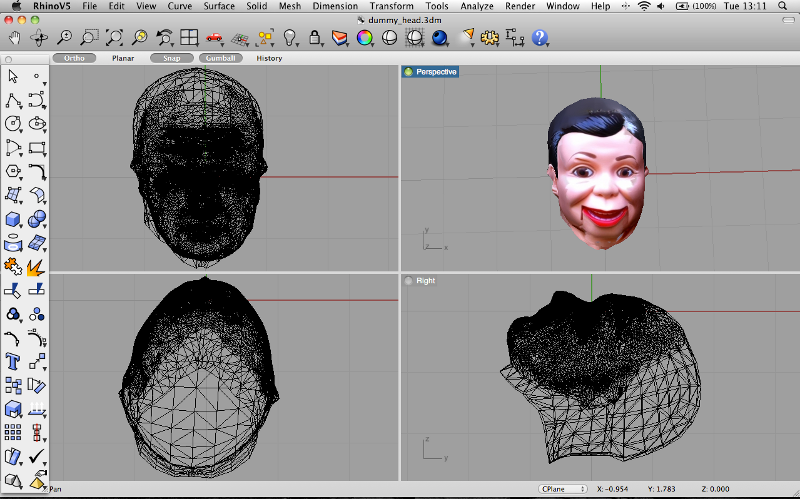

With 'iFace3D' the subject is scanned for 15 seconds from one side view

to the other - the result is uploaded to a server and the completed

mesh and texture are produced (obj/wrl/jpg). To create a good scan the

motion must be constant, the lighting must be even and the subject must

be in front of a wall.

I have a head from a ventriloquist dummy which I want to use as a guide

for my final project. So I used this for a trial. The result was good

and I imported the obj file into Rhino:

suspitition

suspitition

At first glance this looks like a powerful and cheap little app but

I suspect that the camera creates the texture file which is

wrapped around a standard head mesh.

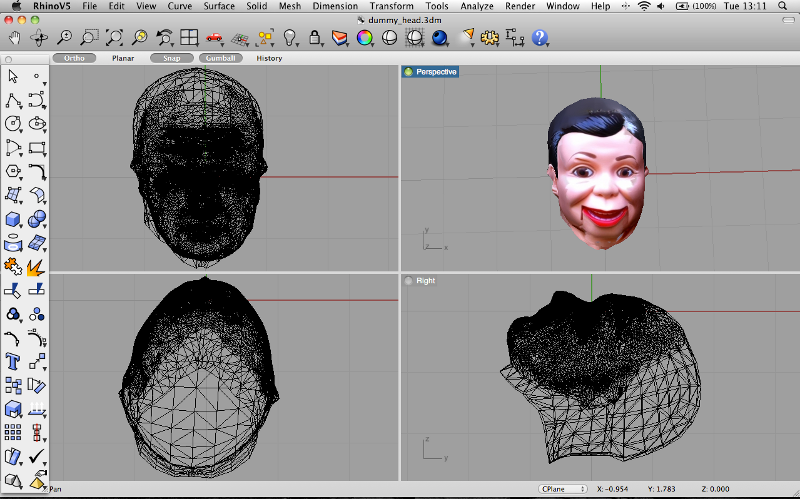

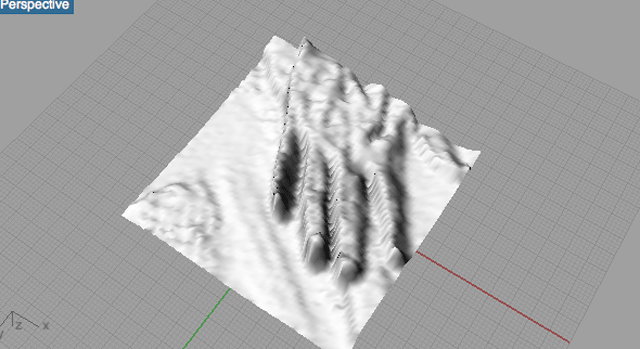

The next app is 3DSurfScan - this creates an obj file - it works on the basis of colour contrast and with some practice can produce surfaces which can be worked on:

My Hand

My Keyboard

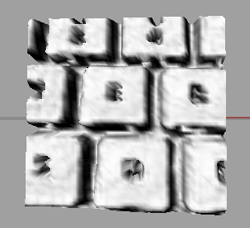

a block

a block

I also tried other apps but none were as good as these two.

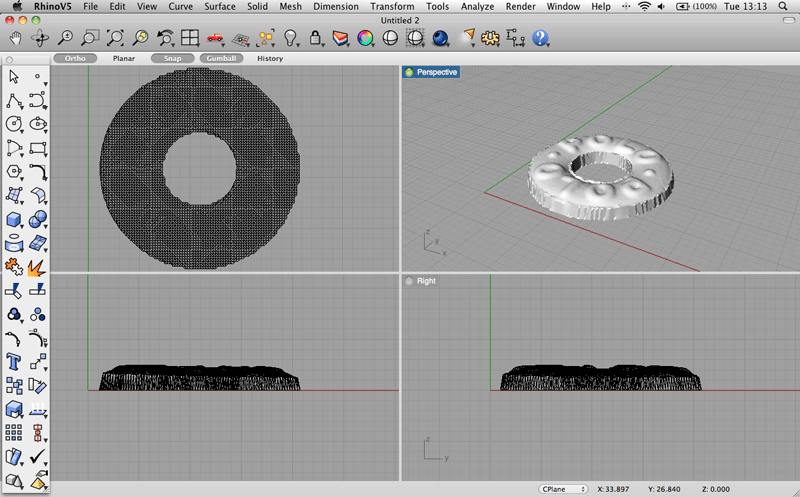

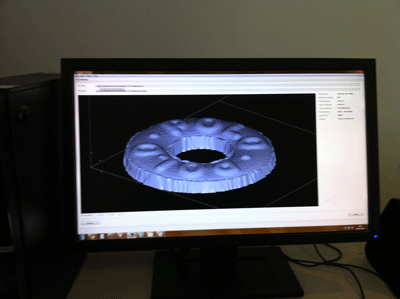

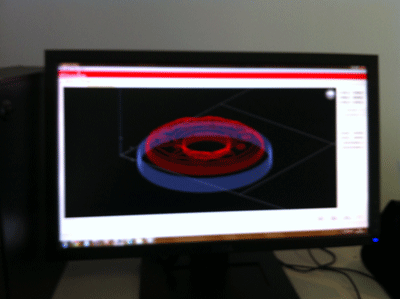

In the Lab, I used the Modela to scan a polo mint. Since this was a rather small object I scanned at .25mm resolution - it took 40 minutes to complete but produced a good result which was imported into Rhino:

This was used for 3DPrinting -

I also took the opportunity to print a prototype joint for my final

project.

I decided to make a simple universal joint and print this out as

small as I could. This would provide some idea of how small the

mecanism could be if it were to be 3D Printed. This photograph shows 2

universal joints printed out and still fixed to the black support

material. However, when separating the first print the white material

snapped - too small and fragile for my purposes - must scale up. This

has demonstrated how the eye and mouth mechanisms could by manufactured

for my final project.