Home >Class Feb 8 Assignment

I have already been working on a snapfit solution for lasercut acrillic. As acrylic is very brittle and also doesn't compress very well, i've desided to go with snapfit instead of presfit only.

I also did some tests to find out how thick the kerf is on our lasercutter. For this i cut some 3x3mm squares. After measuring them, i found that the holes were 3.2x3.2 mm. from this i concluded that the kerf is .1 mm.

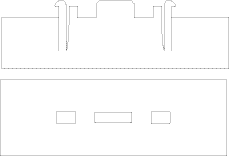

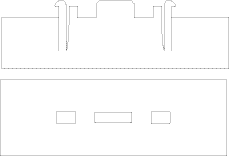

The material i'm using is 2.85 mm thick, do to make my cutout fit, i need to draw it at 2.65mm

I've set my grid in illustrator to .05 mm (1cm grid with 20 subdivisions)

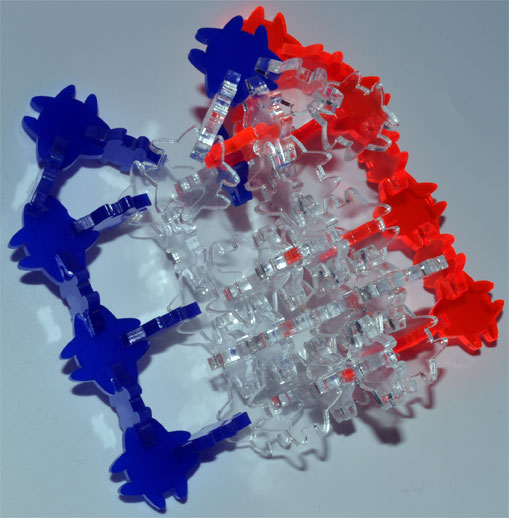

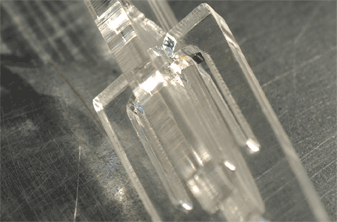

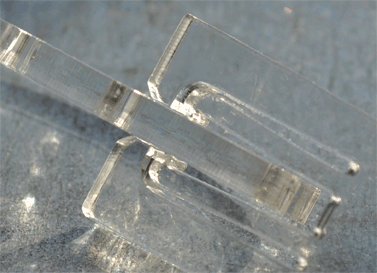

The next iteration towards a kit was the following:

this design also includes stress relieves around the corners/ dogboning to make the snaps sit flush with the other piece

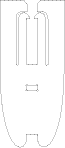

I then found that the front part (as in the detail) made a perfect snap connection with a lasercut edge (of the same material ofcource). after investigating a little further i noticed that cutting a line trough the acrylic creates a little ridge on the surface along the edge of the material being cut.

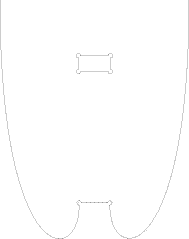

Above is the final design for my snapkit. A next step could be making this design parametric so it will be easly adaptable to other thicknesses. The material choice will ofcource be limited to materials that create a ridge like acrylic does.