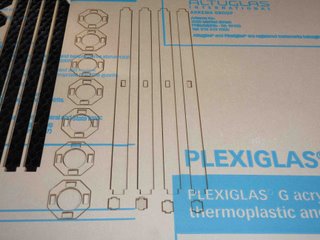

My Pressfit project is a miniature size winerack. I used 0.11" thick clear acrylic. I am not sure how we ended up with 0.11" thick acrylic. Quality control at the "Acrylic Factory" was not so good that day.

The only reason this matter is for the little square notches on the octogonal pieces, these are dimensioned to pressfit with 0.11" thick acrylic and need to be resized for 1/8" if you want/desire to replicate this project. (svg File) (pdf File)

The settings for the Epilog laser were:

Auto Focus: checked

Vector cut: checked

Speed: 15%

Power: 80%

Frequency: 5kHz

Piece size: this is up to you but I used 24x12in

Measure twice!

With the laser cutter I can afford to measure once:).

But make sure to cut plenty of extra pieces.

The octogonal pieces, once you insert the long slender "ribs",

will be under a lot of stress around the square cut outs

and many of them will brake as they are put together.

To make each cylinder I used 4 "ribs", the long slender rectangular pieces. For the back/buttom I used an octagonal piece that does not have a circle cut out in the middle. For the top octagonal piece I left an opening in case I want to put something in there :). I made some small tabs to connect two or more cylinders together, I connected 3 for the buttom raw and 2 for the top raw. Right now I do not have a way to connect all six of them together. Work in progress.

2 Birds in one shot.

Since it was Valentine's Day on Monday

and I had to finish my pressfit project

I decided to "kill 2 birds in one shot".

I added a little something something and

and I gave this to my hobby as a Valentine's gift :).

Top view of an assembled piece.

Everything assembled.

I used 6 total pieces for my project.

The idea is that one can use as many pieces

as they wish, depending on what they use it for.