SUMMARY

As by snow on a bell,

With which the hour is rung

For the evening meal...

(Heidegger, Elucidations of Hölderlin's Poetry)

The initial design called for a bell making machine which removed material from a rotating platter. The current effort produces models out of ABS plastic using a Makerbot Cupcake 3D printer by adding material. The reason for this turn hinged on the activity of our "bootstrapping" lab to get various pieces of make-it-yourself equipment working, these being the MTM SNAP and the Cupcake. Construction and programming of these tools took some time, which obviated the need to create yet another device to develop the proof of concept model described here. Rather, the efforts undertaken over the past year now hint at new paths for the construction of a bell pattern machine for next year! A modified version of Le Big Rep may be undertaken to complete this project. One potential advantage with the additive process is that surface decoration may be built into the pattern as it is constructed. With the tools currently at our disposal, the diameter of the mouth of the bell described here is limited to about 3 inches, instead of the 12 inches originally envisioned.

The inspiration for this project came from the work of the 16th century metallurgist Vannoccio Biringuccio, who describes in his treatise The Pirotechnia an algorithm for the construction of bells. Presumably the form of these bells had been determined empirically through the ages, and passed from generation to generation of bell masters (..."a thing that has been discovered by the masters more through experience than by geometrical rule"... op. cit. p.272) Birringuccio describes the pattern of their construction, and presents:

1) a Bell Scale (above, probably not to scale in your browser) which relates the weight of a bell in pounds to the thickness of its rim, (eg a 10 pound bell has a 1.31 cm rim thickness, 20 pounds 1.57 cm, etc.) and

2) an algorithm for the construction of 2-dimensional patterns based upon this rim thickness, which when incised on strickle boards which are rotated around an axis, carve inner and outer surfaces in suitable materials. Bells of various sizes may then be constructed, from 10 pounds to 10,000 pounds, and estimates of material requirements for casting rapidly assessed.

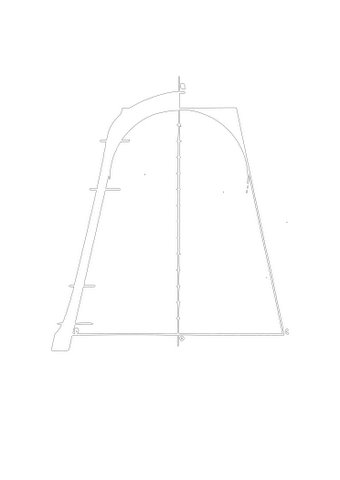

Biringuccio's method of construction is given as follows:

The unit length for the design of a bell of any weight is the rim thickness, obtained by actual

measure from the bell scale (above). In laying out the bell, first draw OA, 14 units long ; then

OB and OC, each 6 1/2 (BC=13) ; then AD and AE each 3 1/2 (DE=7) . Complete the trapezium

DECB. Round the top by judgement or by drawing the part circle FAG. (The circle tangent to

DB, DE, and EC touches the sides at a height of about 10 1/2 ; later instructions allow the straight

side to continue up to about 12, and this is shown in the drawing .) Extend DB to H, making BH= 1.

Draw HI =1 and the diagonal BI. Draw IK parallel to BH and also of length 1 . [note "H" lies one

unit under "B", and "I" one unit under "K", cut off photocopy] The curvature of

the outside is established by connecting with a smooth curve the points K, L, M, N, and P, which

are at heights of 0, 2/3, 3, 9, and 12 units above the base line and correspond to thicknesses measured

from the straight line BD of 1, 2/3, 1/2, 3/7, and 1/2 units respectively . The curved crown is made

the same thickness as the rim ; i .e., AQ= 1 . Templates are cut to the shape of the inside and outside

of the bell and are used as strickles to shape the moulding clay.(The Pirotechnia, p.453)

My method of construction is as follows:

I took a scanned image of Biringuccio's construction (above), and imported it into Inkscape, and transformed to a vector file. I then scaled it and read the constants off with a graphical overlay, and inserted into the polynomial expressions below for the inner and outer surfaces of the bell. Now the pattern consists of digital information which is transformed by a computer program, where the two volumes are subtracted, resulting in a bell. Using the open source program openScad, it is then exported as an .stl file and imported into replicatorG, where it is converted to g code for output on the Makerbot Cupcake.

The OpenScad code to construct the bell is as follows:

/* Adapted from The Pirotechnia of Vannoccio Biringuccio

Height = 16 * t

Diameter 15 * t

The following parametric equations can be used to design a bell of any given

rim thickness "t" - the limits are what the machine can output. A 0.5 centimeter

thickness is chosen here to output a model which will fit on the bed of a Makerbot Cupcake.

Changing the rim thickness "t" will yield a bigger and heavier bell! */

t= 0.5; // thickness of bell rim in centimeters (or whatever units you prefer)

difference(){

union(){

rotate_extrude($fn=200) polygon( points=[[(7.85*t),0],[(7.65*t),t],[(7.05*t),(2*t)],[(6.7*t),(3*t)],[(6.4*t),(4*t)],[(6.2*t),(5*t)],[(5.95*t),(6*t)],

[(5.7*t),(7*t)],[(5.5*t),(8*t)],[(5.25*t),(9*t)],[(5.05*t),(10*t)],[(4.8*t),(11*t)],[(4.6*t),(12*t)],[(4.4*t),(13*t)],[(4.1*t),(14*t)],

[(3.1*t),(15*t)],[(.3*t),(16*t)]] ); //outer surface of bell

}

rotate_extrude($fn=200) polygon( points=[[(6.75*t),0],[(6.5*t),t],[(6.3*t),(2*t)],[(6.1*t),(3*t)],[(5.85*t),(4*t)],[(5.85*t),(5*t)],[(5.4*t),(6*t)],

[(5.15*t),(7*t)],[(4.95*t),(8*t)],[(4.7*t),(9*t)],[(4.5*t),(10*t)],[(4.25*t),(11*t)],[(4.0*t),(12*t)],[(3.5*t),(13*t)],[(2.6*t),(14*t)],

[(.3*t),(15*t)]] ); // inner surface of bell

}

Coordinate [x,y] pairs define the inner and outer polygonal surfaces of the bell, and the difference between the two yields the volume of the bell. Note that my zero is one unit below that given in the illustration, and that 16 points define the outer surface, and 15 the inner surface. Also, a small aperture is left in the crown of the bell through which the clapper and cannon assembly may be attached.

The .stl file is opened up in ReplicatorG, and in this case "scaled up" to make a larger build. The theoretical time to fabricate a bell of this size is 45 minutes to an hour.

It was observed that the ABS plastic was not quite hot and sticky enough, as the circular arcs were sometimes pulled into line segments, instead of adhering and following the prescribed circle below. Midway through the build in this test, things stabilized for a time, until the belt driven drive mechanism of the z table missed a couple of steps, and knocked the pattern off the table. Time for a reset and a rebuild! We are able to control the temperature of the ABS plastic, and the rate of deposition in the xy plane, as well as the z step. However, experience has shown that the Makerbot seemingly requires a lot of persistence, patience and low animal cunning to produce a successful build.

CONCLUSION

The method and the result of bell pattern making presented here is not that different from Biringuccio's time. Indeed, a 16th century craftsman could turn himself over to this technology without too much effort. Ultimately, the pattern will be used to create a mold into which bell metal will be cast in the usual way.

What is different in our respective times is the picture of what a bell is. Today the pattern to make the bell can be expressed as a digital approximation, and its construction and assembly accomplished by a machine. Now when the bell tolls, does it strike the same tone in body and spirit of men as it did half a millenium ago?

Future updates for this project will be hosted at campanologia.com

Window with falling snow is arrayed,

Long tolls the vesper bell,

The house is provided well

The table is for many laid

Georg Trakl, A Winter Evening