FabISP Project Tutorial

Milling the board on the modela was not

too difficult due to the software but it was important to make sure that the

board was fastened down well to the bed of the modela.

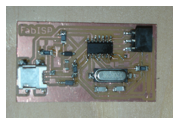

I love the look of the boards after they are cut. It always reminds me of a piece of

modern art. After all the components are added the board takes on its purposed

look and displaces the art with function.

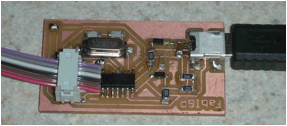

Putting the components on was quite a task. They were very small and I was not a

practiced solder gun wielder. The

task took all my attention and I forgot to take pictures until the soldering

was well along. The most serious

problem was a serious difficulty getting the solder to flow. We raised the temperature of the gun

from 700 to 755 and then changed the tip. Finally I used a hammer to flatten

the wire solder and then cut it into chips. The pounding was very rewarding.

The chips of solder helped with the small pins on the centipede or

microcontroller and the USB chip had very fine pins to solder and keep the

solder on the pad and trace. During this process I also experimented with using

flux to see if that would help with the solder flow.

Although I knew to orient the small chips I didnŐt pay attention

to the orientation of the microprocessor and had to undo all my careful

soldering. We didnŐt discover the

error until we tried to program the ISP.

The reoriented chip

worked much better and the ISP is

complete.