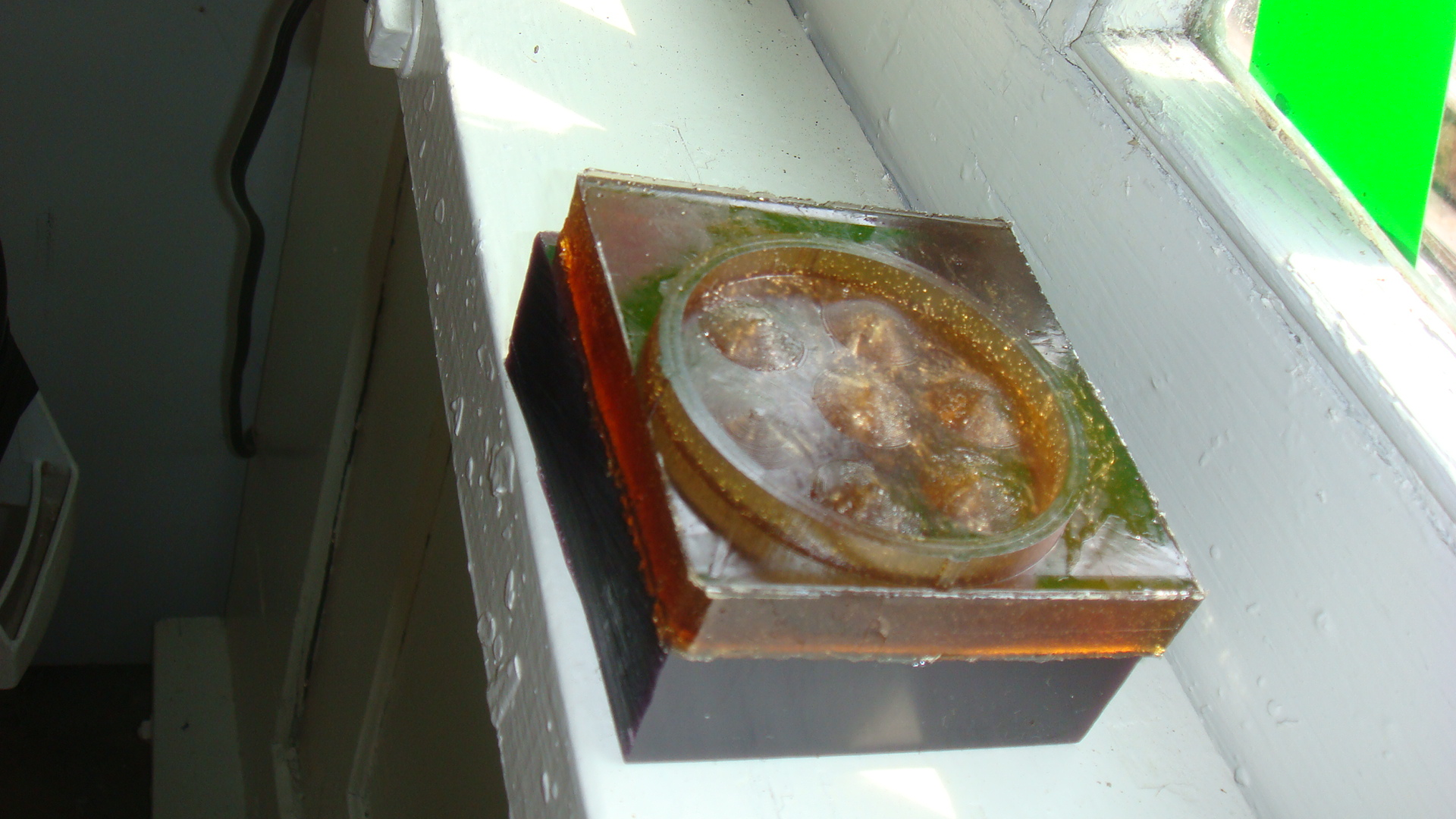

I measured and designed an insert to be used to convert a candy container

into a small watercolor box. I used Inkscape to design a 3D image of my paint

box insert, saved it to a .png file and then output it to the Modela to create

a 3D wax mold.

Once this was done I created a negative mold and cast my paint

box insert in a composite. It took around 4 hours to cut out my 3D mold on the

modella, and an hour to create the negative mold.

I then placed cardboard around the edge of my wax mold with a half inch

section at the top to create a simple mold box. I used Carpet Tape to keep

the cardboard attached. Then I wrapped it around the outside of the wax mold and

cardboard again with packing tape to make sure it was secure.

I used Sooth-On PMC * 121/30 Soft and Flexibel Liquid Rubber Compound to make an

exact reproduction of my original wax mold of my Inkscape Design. I followed the

instructions carefully. When measuring I used poured water into my cardboard mold

quickly to see how much material I would need of the two ingredients. Once this

was done I quickly poured the water into the measuring cup to see how much it

took. I divided this by two. At this point I filled the measuring cup with this

amount and poured it into one of the smaller cups so I could mark the side of it

with a pen. This gave me the amount of that I was going to need of each

ingredient. I poured the water from the first cup into the second one and marked

it in the same way. After dumping the water out and drying the cup I poured

Part B into the first marked cup to measure before putting it into the large cup.

I repeated this process for Part B. Once each of the one of the two smaller cups

ingredients were combined into the larger one I used a cutting back and forth

motion to mix, NOT a circular stirring motion to avoid creating bubbles. After

mixing the contents thoroughly I poued it over the mold and let it cure into a

solid, flexible rubber mold. When it was firm I removed it to reveal my new mold.

I made the final insert by using a liquid plastic to pour into my new rubber mold

and let it cure. When it was done curing I took the solid plastic out and was

ready to make another.

Altoids Container

Modella design

Modella design

Modella design