Computer Controlled Cutting

This week's assignment was to create a press-fit construction kit. I decided to use the laser cutter and to make the kit out of cardboard.

I initially had to do some testing to see how to obtain a good press fit between tabs and gaps, taking into account the width of a vector cut line with cardboard (approximately 0.3mm) so I made the gaps 0.5mm smaller than the nominal size and the tabs 0.25mm larger. This should in effect give an interference of 0.15mm.

I decided to keep it simple and design only 3 components - square, triangle and hexagon and fit as many as possible on one piece of cardboard

To vector cut 6mm cardboard I usedthe following settings:

Speed = 30%

Power = 90%

Frequency = 2,500Hz

I did have a little bit of trouble getting the pieces out as it hadn't cut quite all the way through so if I ran this again I would increase the power to 95%

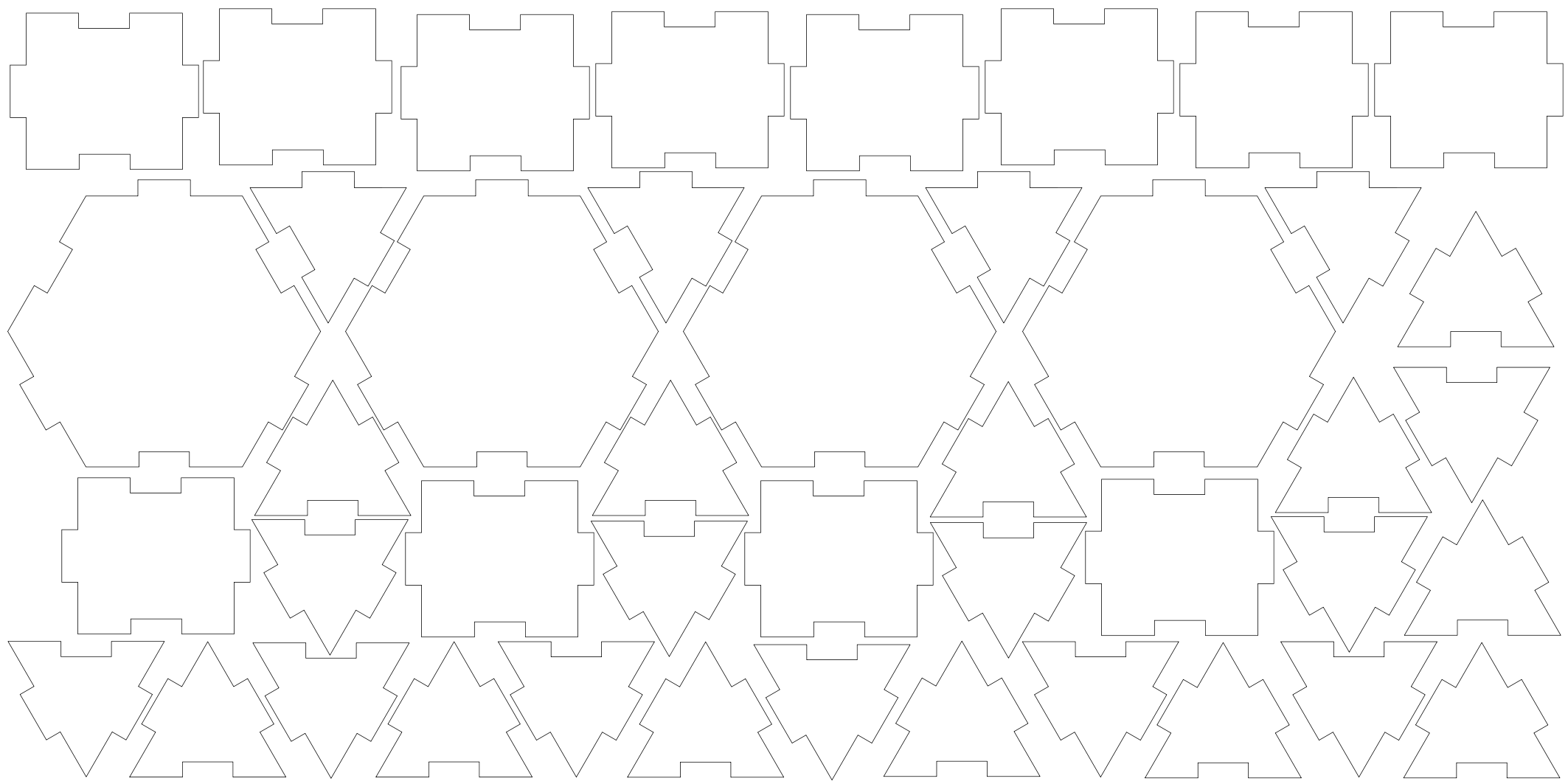

These are the resulting pieces:

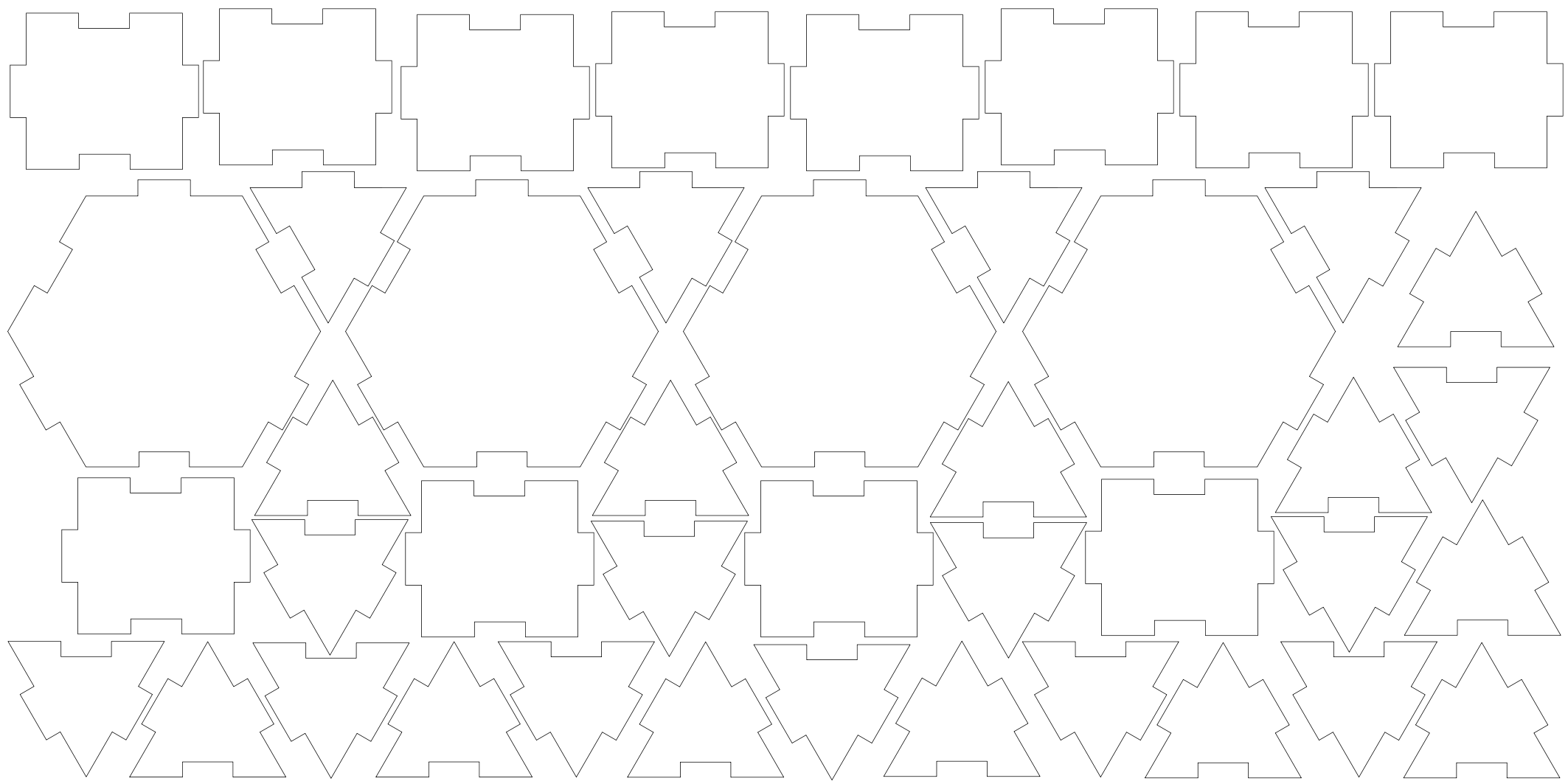

And these are two of the models I made (I am not the most creative person so please forgive me!)