Work In Progress Drawers

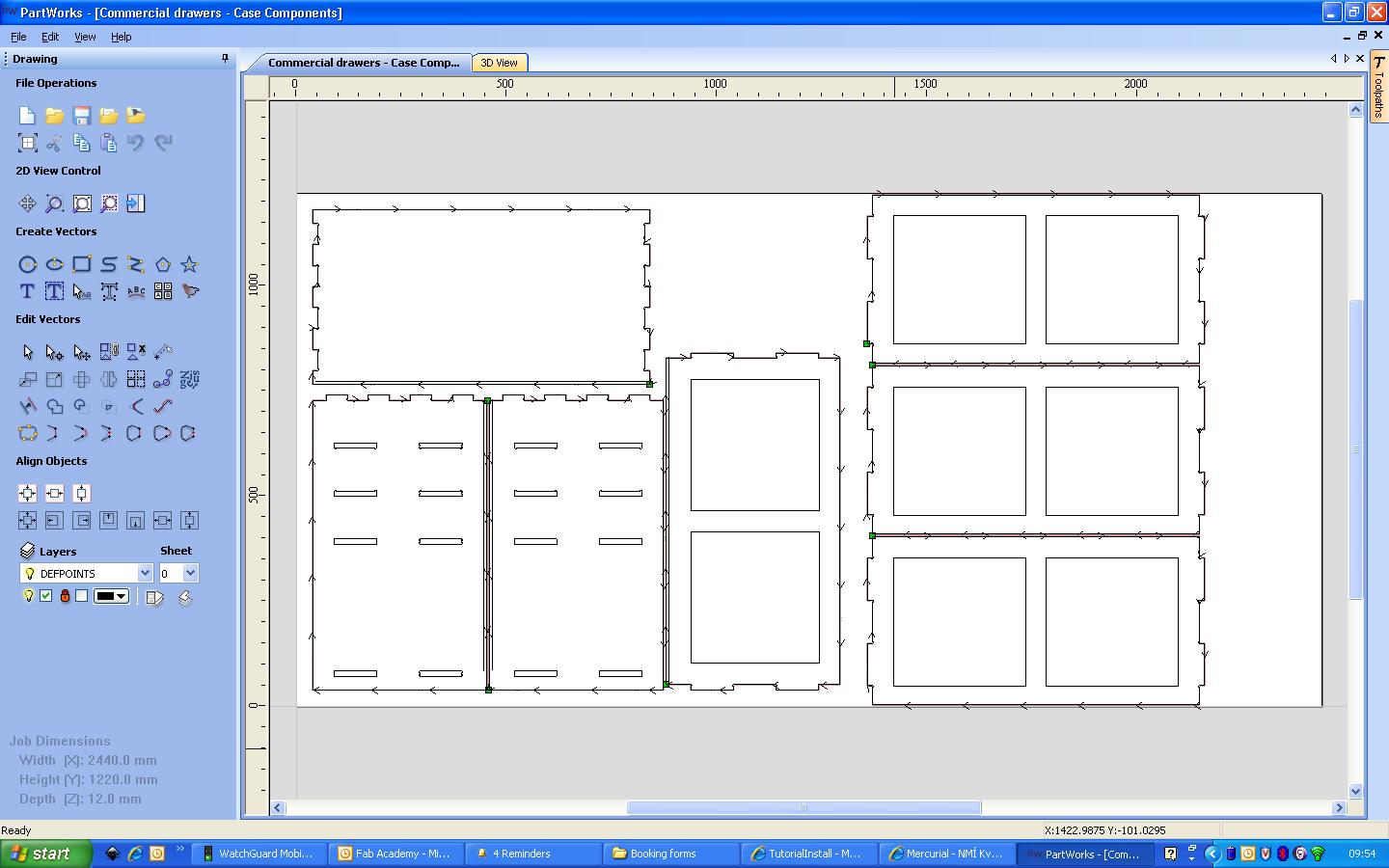

The drawers were designed in 2D using Partworks V2"

The main material used was 12mm MDF as I knew this worked well with interference fit

The drawer bottoms and case back were made from 3mm Fibreboard

Corner joints were made using a square 'dovetail', the gaps being equal in size to the tabs.

The joints for the drawer fronts were 10mm deep pockets about 5% bigger than the tabs

All internal corners were given a 'dog bone' fillet to prevent internal radii

All parts were cut with an 8" upcut 2 flute spiral solid carbide tool at 15,000RPM and at 3.5 inches/second.

The spindle speed has been arrived at through experimentation and the feed speed was calculated from recommended chip load in the Onsrud catalogue

Cutting all parts took about 2 hrs

The final product was assembled in about 1/2 hr with a rubber mallet and no glue, nails or screws!