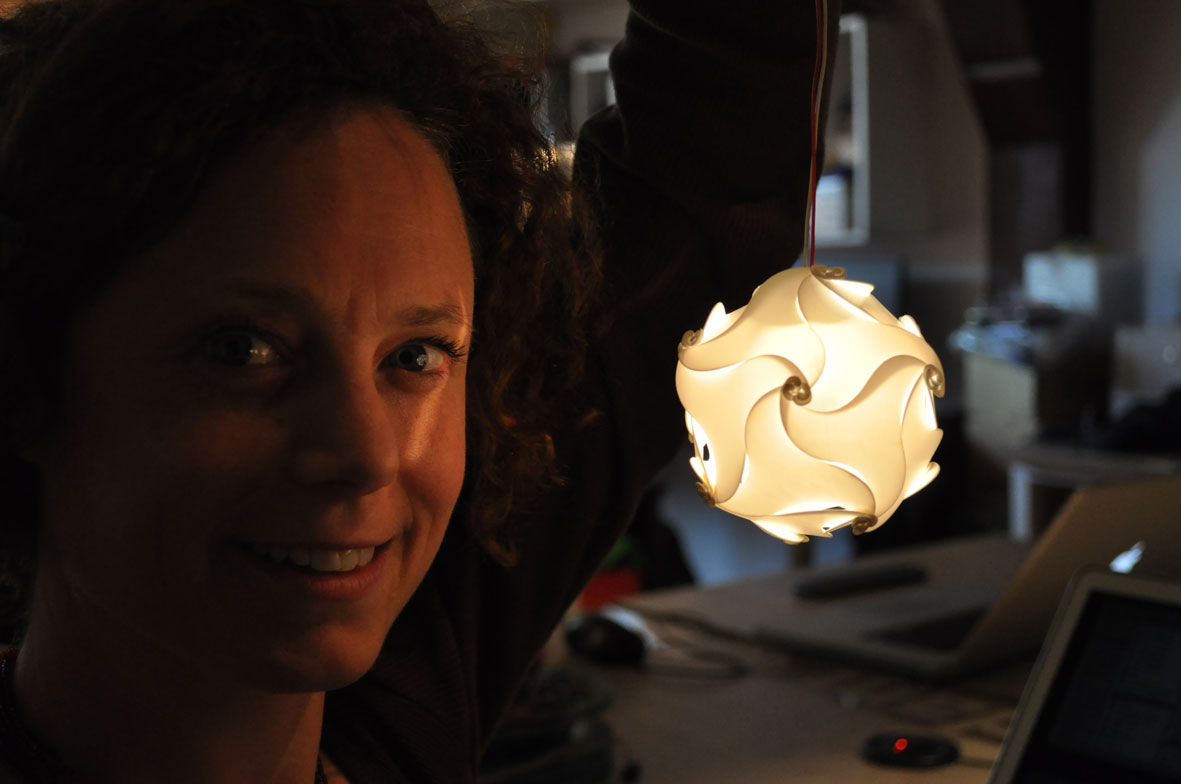

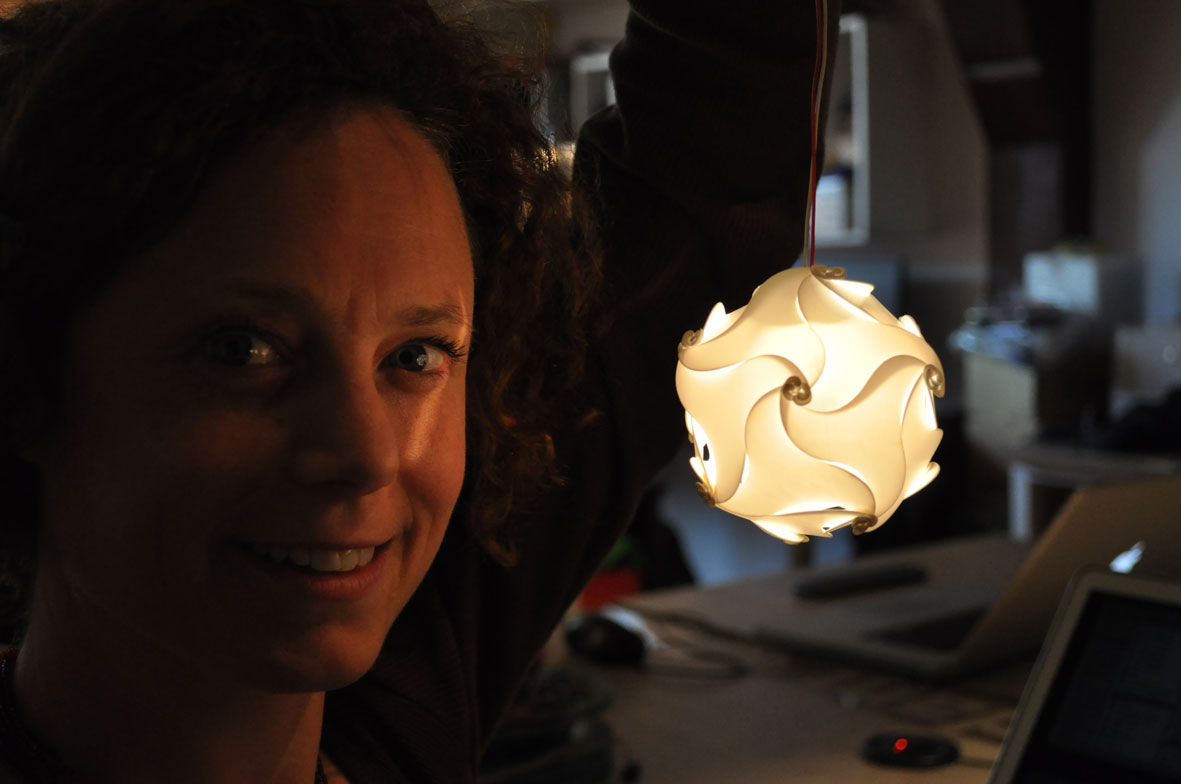

Lamp

Assignment for this week:

Design and make a press-fit construction-kit

I was inspired by the Danish designer Holger Strom. He designed a lamp

called IQ light. IQ light is a self assembly lighting system made up of

interlocking parallelograms.

Lamps of various shapes and sizes can be constructed by linking

together the identical elements.

Instead of a parallelogram as a basis for constructing the sphere I use

a curved triangle. I made the drawing in illustrator CS2. I used the

laser cutter to cut these patterns out of a piece of polyethylene

sheet.

Techniques:

- adobe illustrator CS2

- laser cutter (speed 5 power 75 ppi 400)

Material:

- probably high density polyethylene sheet ±1 mm;

(manufacturer unknown since I used a left over).

Method:

- Before cutting I wanted to make a reference sheet

to find out the

ideal laser cutting settings. With this board I want to explore these

different settings linked with various materials.

Findings:

- I'm still busy with the assembling of the different variations.

- It is better to use a harder material, e.g. polyethyleen, because it

is

stronger and less stretchable.

- I placed the triangles in a nice looking order on the sheet, which at

first was

not very efficient, material-wise. But from the left-over I made an

alternative lamp.

Result:

Box

I wanted to give the traditional finger

joint a special look. (under construction)

Techniques:

- adobe illustrator CS2

- Rhino V5

- laser cutter (speed... power...dpi...)

Material

- PMMA (polymethylmethacrylate) in various colours