Making a circuit board

Assignment

Make the FabISP in-circuit

programmer

Result

photos

Techniques/tools:

Roland modela with cad.py software (new software not installed)

Cutting out the traces: 1/64 bit

Cutting out the board: 1/32 bit

Solder iron temperature 75 x10 F

Tweezers

Magnifying glass with light

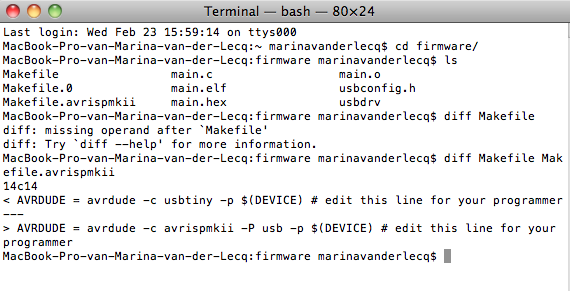

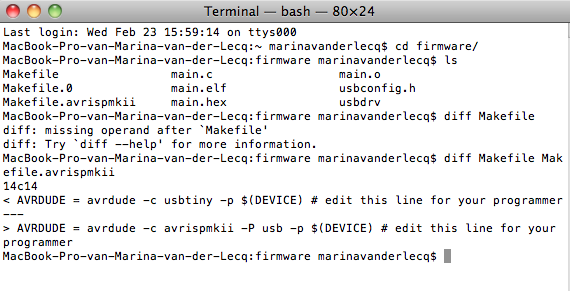

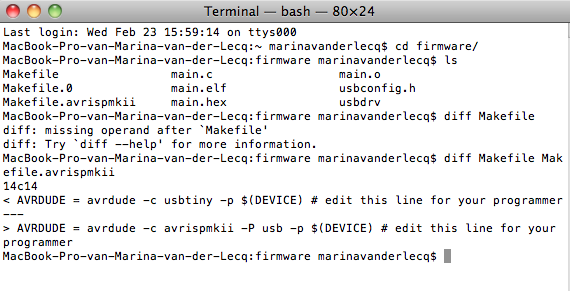

Programmer: AVRisp MKII

Software: AVRdude and cross Pack AVR

(both open source)

Materials:

png files: fabisp.png and fabispdim.png (archive)

double sided tape scotch 3M

FR1

Wire soldering lead/tin with flux, kester connection innovation

Findings:

Machining

When changing the end mill, I fastened the mill a little bit deeper

into

the head of the milling machine, pressed the view button. Then moved

the head above the middle of the FR1 plate. I pushed down to a certain

point. The mill didn't go any deeper anyway. So, I loosened the sews

of the head and put the end mill on the plate. Than fastened the screws

again and gave the order to the machine to mill the outline of the

plate to loosen the traced circuit board from the greater FR1 plate.

But the board came not entirely loose from the plate, while the

settings in the computer were correct. I think when zeroing mill, the

mill stopped from going down any further. Probably the head has reached

the minus Z endpoint and therefore stopped from going down deeper.

For resetting the modella, I didn't not turn of the machine as written

in the tutorial. I first pressed view and than at the same time

the up and down button. The light of the modela is winking.

Soldering

I find soldering a nice and relaxing job.

Downloading and adapting the

programs

I find it amazing how a microcontroller works and adapts to your

needs. Without any further mechanical action I can load a program on a

chip and make it do something. I find it magic, where command lines act

as spells. Now I have to learn the spells.

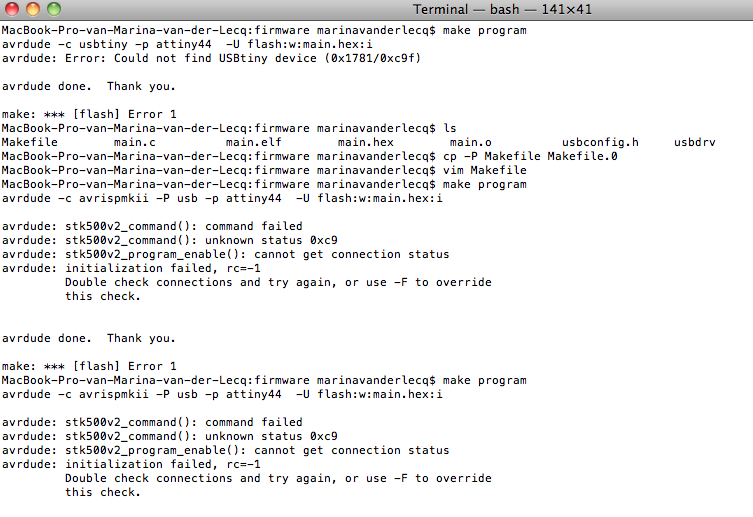

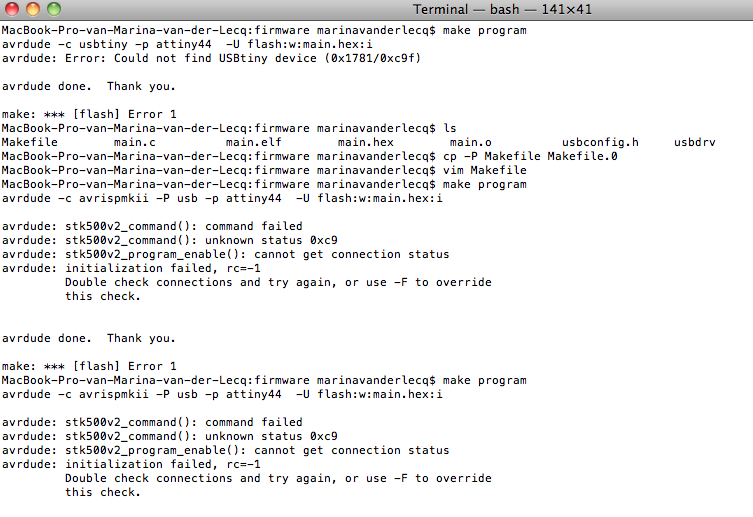

Connecting the Fabisp with

the working programmer

The

connection between the working programmer (AVRisp MKII) and my fabisp

didn't succeed the first time. The trouble was situated at R5 499.

Instead of soldering a resistor of 499x10^0 I placed a resistor of 499

x10^3. The resistance was too big therefore the current was too low and

I didn't got a signal on the USB interface. I desolder the component

and replaced it for the 499x10^.

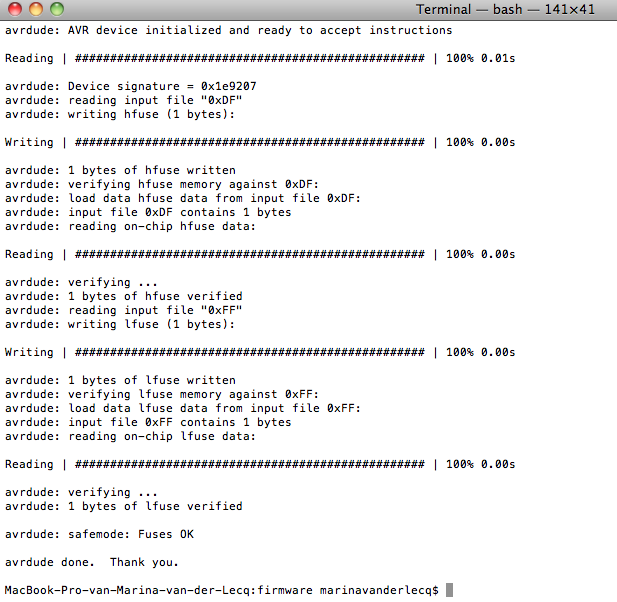

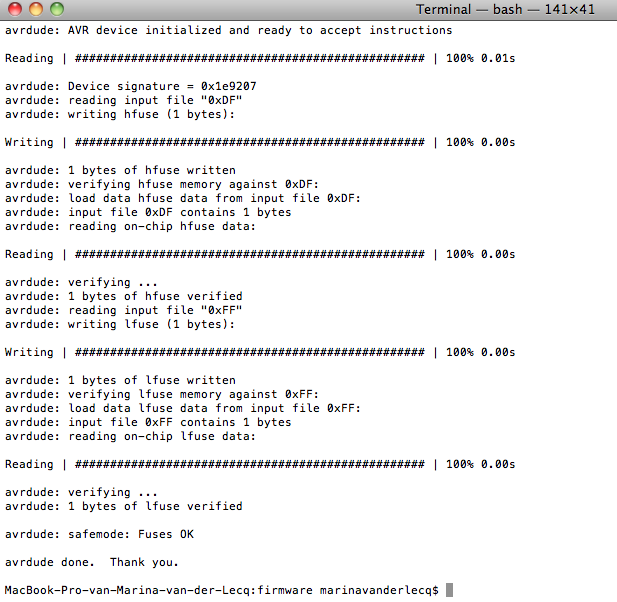

Programming the ATtiny44

After this conundrum of the connection was solved, programming the

ATtiny44 turned out succesfully.