Principles of the heart rate sensor with photo diode

and infraredlight LED:

The principle of measuring the heartbeat with a light source is based

on the transmitted and absorption characteristics of oxygenated and

de-oxygenated hemoglobin. Oxygenated hemoglobin absorbs more infrared

light and allows more red light to pass through while deoxygenated

hemoglobin absorbs more red light and allows more infrared

light to pass through. Red light is in the 600-750 nm wavelength light

band. Infrared light is in the 850-1000 nm wavelength light band.

Findings

- The first

version of the heart rate

sensor, I tested with the oscilloscoop with a light sensor

(...) and

an infrared light

(...)

(...)

showed signals. Unfortunately

it was not

my heartbeat. It had been just very exceptional as

it

would

operate at once... I decided to add an amplifier, which should enhance

the signal. I decided to use the circuit previously

found on the internet, because in that

example,

an

amplifier was used.

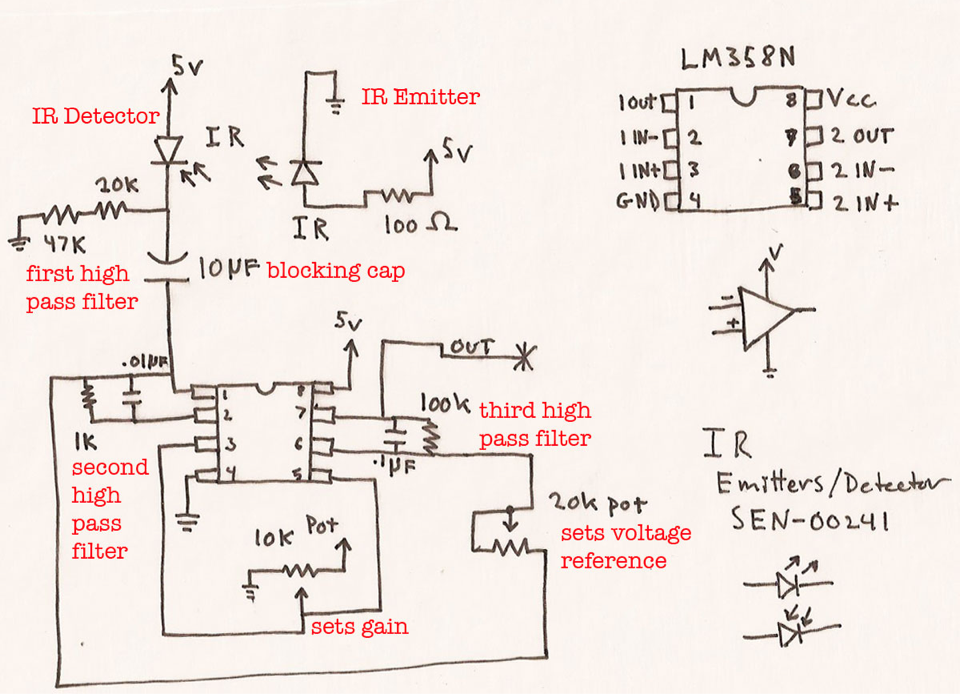

This is the image of the circuit

and this is the link: http://www.johnhenryshammer.com/TEChREF/opAmps/opamps.html

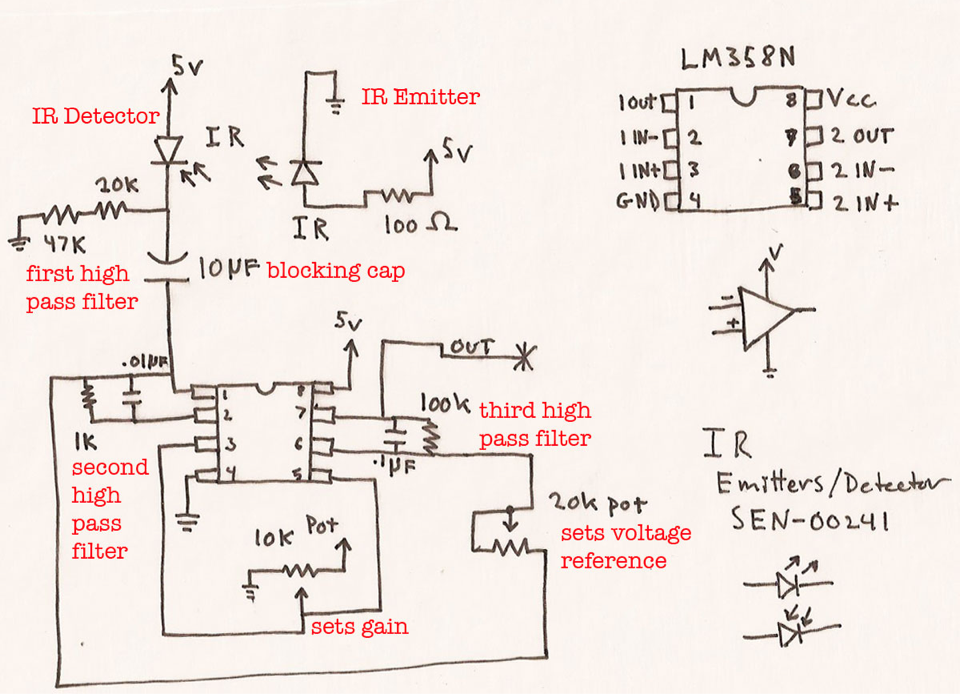

I have used the eagle software to enter the design in order to mill it out on the MODELA later on. The pictures

below

shows the results of the eagle-software.

Schematic

layout

Board

layout

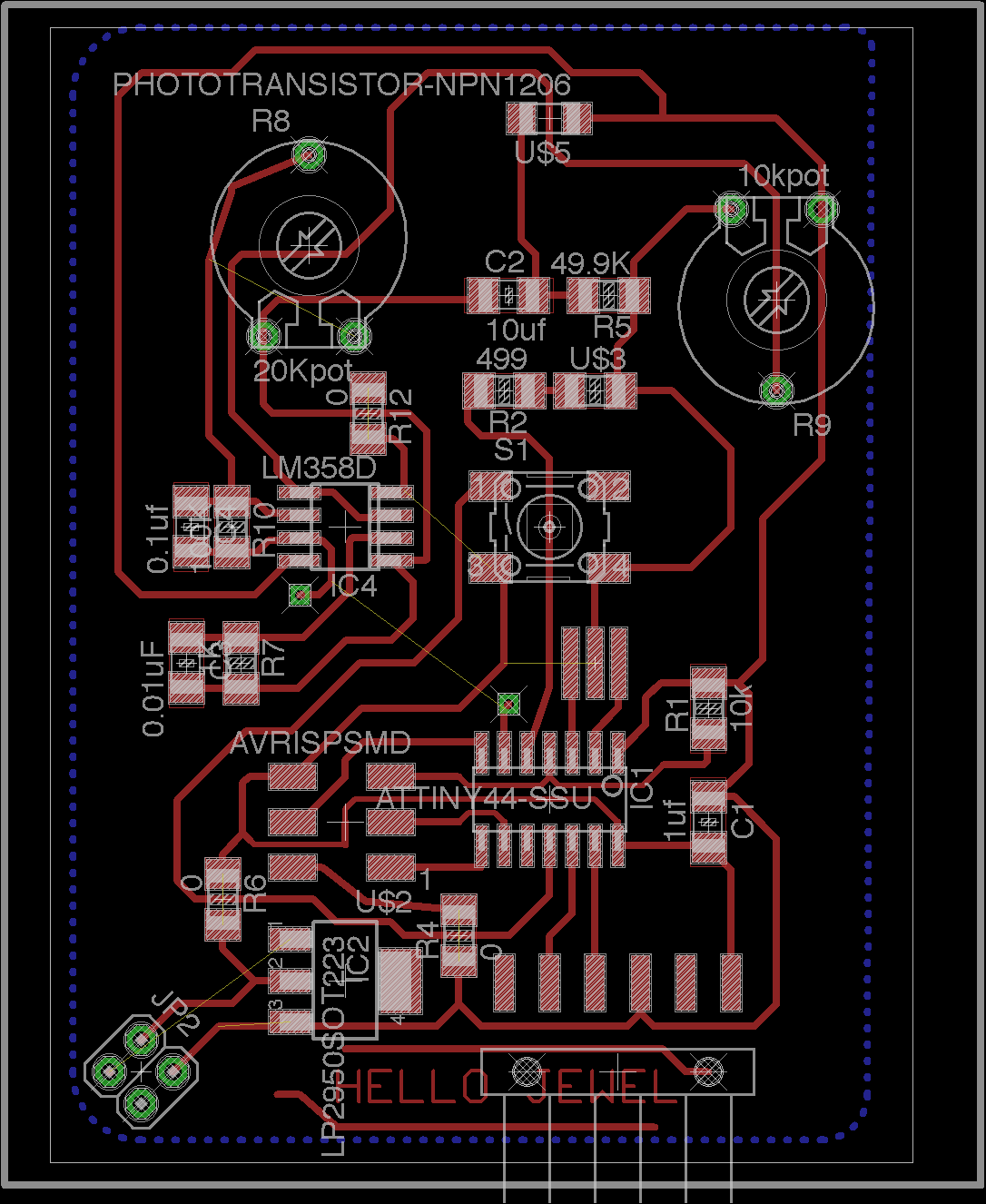

physical

board

At first

it did

nothing. I could not program the chip. Here came

debugging

into play.

1) I checked the soldered and the schematic again.

- The potential meter was connected wrong in the schematic

- I soldered the LM358 other way around. I learned more about

the different packages of the components.

- I think I used a wrong capacitor. I probably had misread.

Instead of 0.01 uF I used 0.1

uF

- At the end I found a missing trace of the voltage regulator. At first

I didn't

connect the board to the 9Volt battery, but

to the

external power supply to the header

to set the board to 5 volts. I

used a oscilloscope to measure its behaviour. Any

movement changed the signal, but

it was not my heartbeat.

Meanwhile

I had a

final

presentation of the fab academy. Time pressure... I wanted

to show something

closer

to what was my design. I decided

to make make

my design

physically. Sometimes

it's better

to start

all over

again. Moreover, you

can debug

better

with

separate

circuitry.

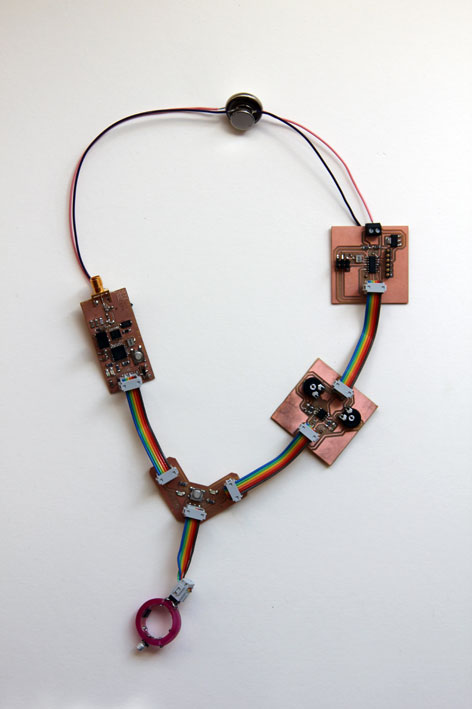

Below is the

result.

The circuit

I have

divided

into five parts: The chip, the amplifier, the LED, the sensor and

the 'hello

radio'.

The board

of the chip include

connections for the batteries, a voltage

regulator and an external

crystal

and some capacitors and resistors.

The board of the amplifier include two potentiometers and two high pass

filters.

The board of the LED include two LEDs and some resistors

The circuit board

of the

sensor and the infraroodled

was made

in a ring. I believe the ring

would

imply

less

movement. I used copper foil and the vinyl cutter

to cut

out the circuit.

The

picture above shows copper

foil pasted in the ring and soldered

components.

This part of circuit include the first high pass filter.

Now debugging really came into play.

I learned more about active high pass filters. The reason ....

fout

ligt in de versterker. vermoedelijk is het filter

design niet

juist. high pass filter is anders aangesloten en gaat meteen van in

naar de out.

zie ontwerp

high frequency laat hoge frequenties door. een hartslag geeft ....

frequentie

optie:

digitaal filteren:

gebruik pin 13 om een potmeter op aan te sluiten die de functie krijgt

van als A REF (external voltage reference)

meet met de oscilloscope je hartslag en zet de weerstand van de

potmeter op het voltage wat je maximaal hebt gekregen met de

oscilloscope. zet in het programma AREF = 1voor de ATtiny 44

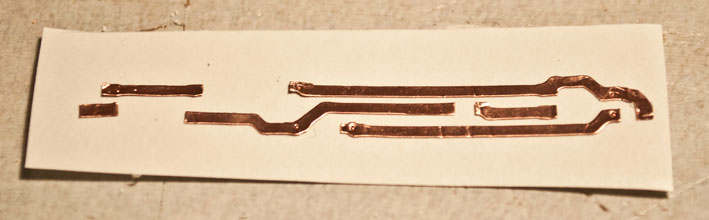

Vinyl cutting the traces in the

copperfoil

1) Open eagle PNG document in Illustrator and then choose live trace

and expand. You can still modify the traces a little. For example, I

made the lines a little thicker.

2) Choose print from the illustrator menu: place the object in the

lower left corner of the screen. Further operations of the vinyl cutter

on the device itself. The width of your file appears in the display.

3) Lift the handle at the back and slide the copper foil under the

wheels. The white marks indicate the possible position of the wheels.

3) Navigate through the menu Select roll. The force and speed I used

for copper foil 1cm = 60g / s

4) Click OK (PC) to print

Result

Copper foil fresh from the vinyl cutter.

Carefully removing the residual material using tweezers.

Ready to transfer the traces.....

with transfer foil.