3D scanning and printing

This week's assignment:

* 3D scan an object

- extra credit: make the scanner

* design and 3D print an object (small, few cm)

- extra credit: edit and print an object

that you scanned

Commercial 3D-scanner

This week I skipped class with Harris. Instead of going to class, we

went to a fair called 'rapidpro', where many suppliers were present

dealing with rapid prototyping products and techniques. This was

precisely the subject that includes all

our lessons.

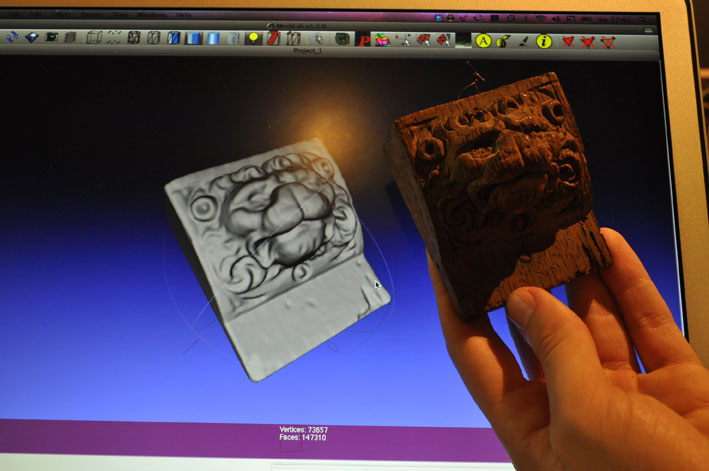

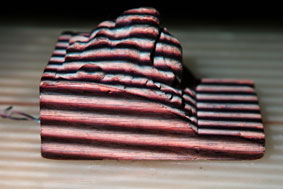

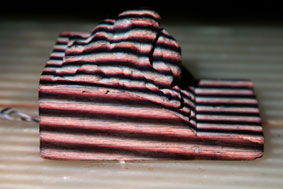

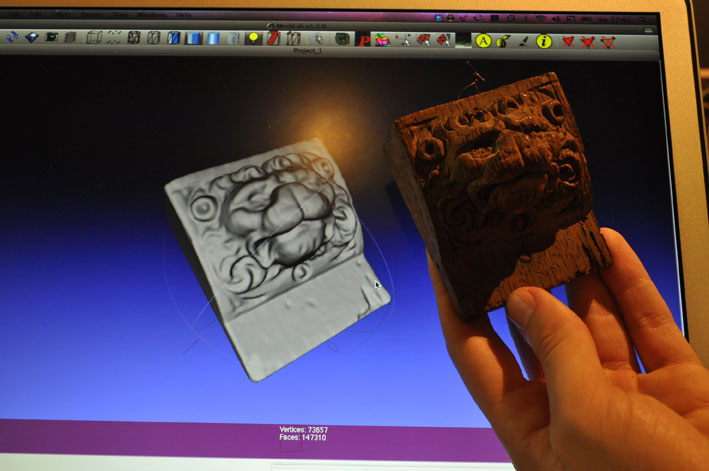

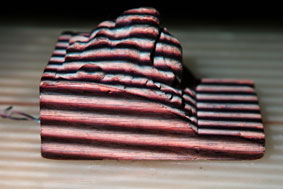

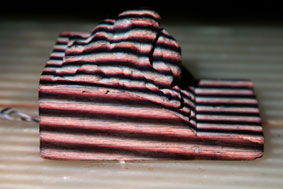

I had taken a piece of wood carving, a lion head, with me from home. I

wanted it to be scanned by as

many different scanners in order to compare results in resolution and

ease of use. I was wondering if one of these scanners can be used for

reproductive purposes and some restoration purposes. Ultimately the

piece was scanned by two scanners the Z-snapper and MMDX 50 3D Scanner

from Nikon.

Tools, materials and techniques

- zsnapper 3D scanner

-

MMDX 50 3D scanner Nikon

- meshlab

- Rhino

- Z-corps 3D printer

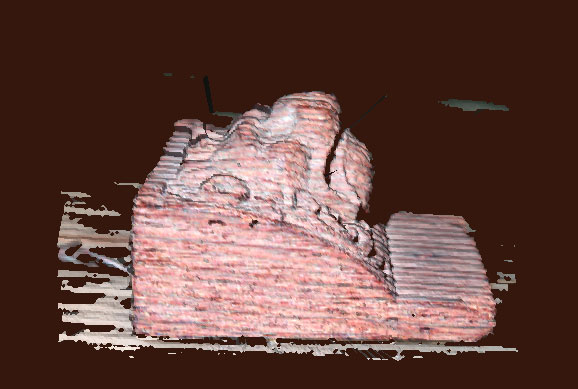

Findings MMDX 50 scanner Nikon

The 3D scanner Nikon MMDX 50 was a handheld scanner that you have to

move around

the object, like as if you are spraying the object. On the screen

you'll see realtime results in a point cloud, so you know exactly where

you left off.

-This scanner is very easy to use. With an inventive adaptation you

could possibly also scan bottom of the object.

- The files are not very large.

- Result is also dependent on how long and how exactly you've scanned.

I had not much influence on that, since I didn't operate the scanner.

Findings 3D zcapper

Coded targets on the object plate were used to determine the

position of the scanner and the object. These coded targets consist

round stickers with a dot in the center surrounded by a circle, that

was broken in different places on each sticker.

- In this set-up the scanner was mounted on a

tripod

while the

object turned. Although it

was also a handheld scanner.

Results

Z-snapper

Nikon

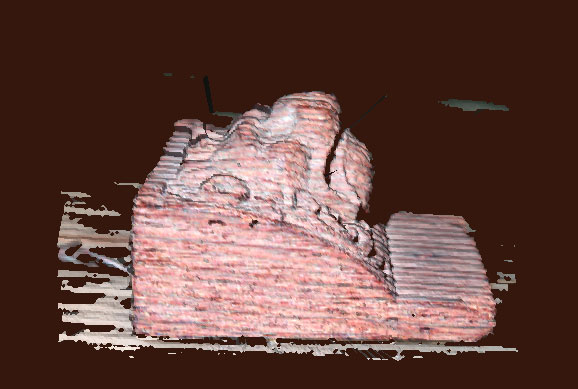

3D scanning by structured light

with three-phase

method

Tools, materials and techniques

a pico-projector

camera

object: wooden carved lionhead

processing

Results

Findings

The result is not very good. In first place, we thought the position of

the camera and Pico projector was not right. We have set up the Pico

projector so that the projection was as a square as it could be

and put the camera in different angles in comparison to the object and

exactly above the projector. Unfortunately without better results.

Then we decided to do calibration of the projector and the camera

properly by using the technique described in this

article. We found a camera

calibration program using OpenCV library on Internet, compiled and

tested it successfuly with a

set

of chessboard pictures. And we planned to translate this

program to Python (OpenCV used in this program has bindings for

Python), because it would be easier for us to modify by adding

projector calibration functionality.

So far this project due to time restrain

Printing

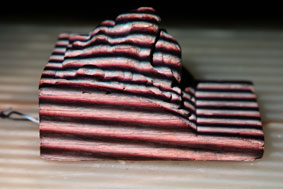

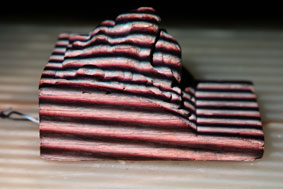

I took the file from one of the scans processed with one of the

commercial scanners. Then closed some wholes

in meshlab and then made it watertide and resized it to a smaller

object using Rhino. This STL file I sent to Fablab Barcelona. They have

the object printed with the Z-Z510 corps. The results of all

printed

objects

from the

Fab-students will be seen in Lima on Fab7.